Method for preparing low-silicon high-titanium ferroalloy employing lower ignition method

An ignition method and high-titanium technology, which is applied in the field of production of low-silicon and high-titanium iron, can solve the problem of high impurities, and achieve the effect of solving high impurities, less impurities and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

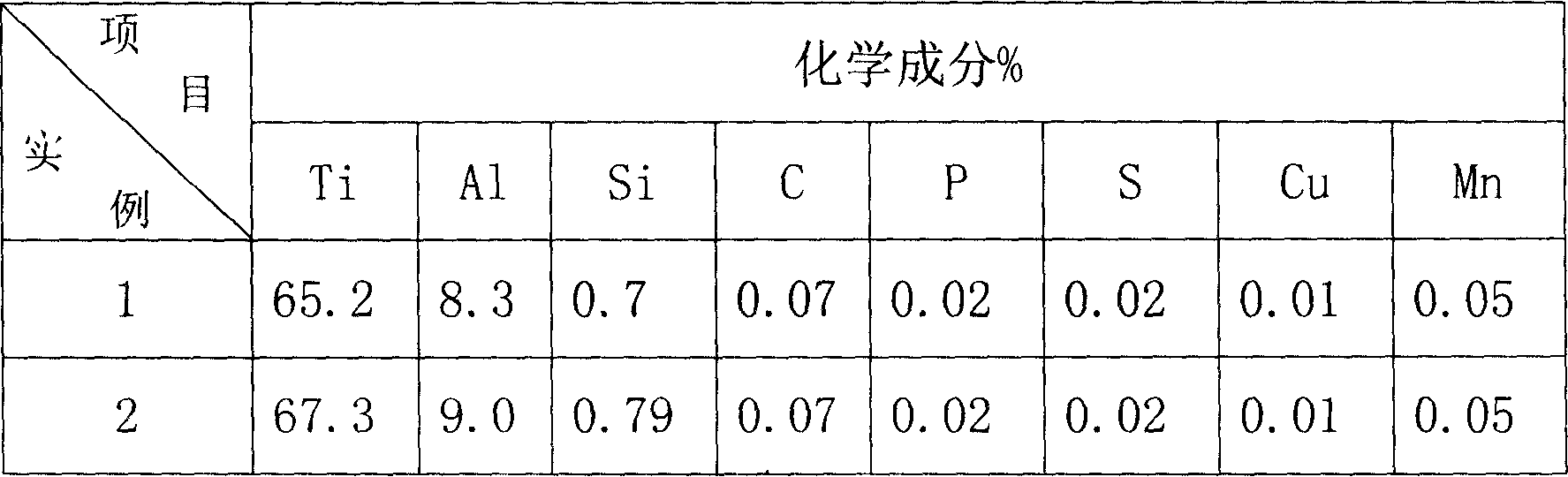

Embodiment 1

[0025] Ingredients: mix and stir rutile, aluminum powder, lime, soda ash, fluorite, potassium chlorate, and iron ore powder in a ratio of 1.0:0.5:0.16:0.035:0.035:0.18:0.08 to obtain a mixture, which is ready for use. The refining agent is (based on 100 kilograms of rutile as the calculation standard) 6 kilograms of iron ore powder, 2 kilograms of magnesium powder, and 1 kilogram of fluorite, mixed and stirred evenly, and set aside. The ignition agent is to mix and stir 0.5 kg of iron ore powder, 0.5 kg of magnesium powder, and 0.5 kg of saltpeter evenly, and set aside.

[0026] Operation: Use magnesia as material to make a pot-bottom-shaped sand nest, then install the shaft furnace on the sand nest to form a smelting furnace, put a small amount of mixture in the bottom of the furnace, and then put in igniting agent, ignite with an electric arc, and let the furnace mix Material reaction, when the slag pool is formed in the furnace, continue to add the mixture to the smelting f...

Embodiment 2

[0028] Ingredients: mix and stir rutile, aluminum powder, lime, soda ash, fluorite, potassium chlorate, and iron ore powder in a ratio of 1.0:0.5:0.16:0.065:0.025:0.18:0.08 to obtain a mixture, which is ready for use. The refining agent is (calculated based on 100 kg of rutile) 6 kg of iron ore powder, 3 kg of magnesium powder, and 1 kg of fluorite, mixed and stirred evenly, and set aside. The ignition agent is to mix and stir 0.5 kg of iron ore powder, 0.5 kg of magnesium powder, and 0.5 kg of saltpeter evenly, and set aside.

[0029] Operation: Use magnesia as material to make a pot-bottom-shaped sand nest, then install the shaft furnace on the sand nest to form a smelting furnace, put a small amount of mixture in the bottom of the furnace, and then put in igniting agent, ignite with an electric arc, and let the furnace mix Material reaction, when the slag pool is formed in the furnace, continue to add the mixture to the smelting furnace, and keep a layer of mixture on the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com