Light honeycomb electrostatic dust removal purifier

An electrostatic precipitator and purifier technology, applied in the field of air purification, can solve problems such as unsuitable installation, complicated assembly, and large wind resistance, and achieve reliable and safe performance, simple processing and assembly, and increased efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

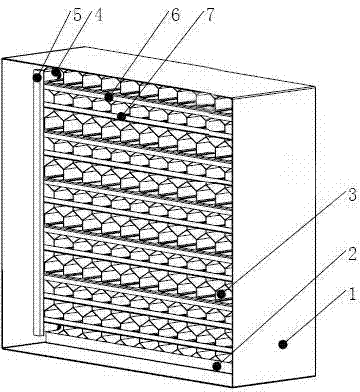

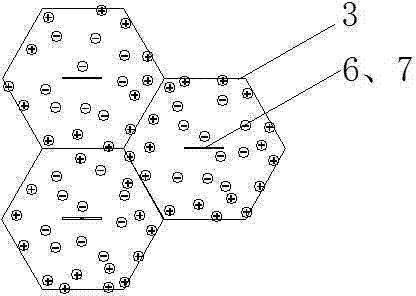

[0017] The structure of this light honeycomb electrostatic dust collector is shown in figure 1 and figure 2 , the fixing plate 2 fixes the aluminum honeycomb dust collecting plate 3 on the plastic-sprayed metal shell 1 through screws, and the integrated strip needle pole 6 and the integrated strip needle pole 7 are fixed on the fixing strip 5 through screws to form a large total needle The pole plate, the integrated strip needle pole 6 and the integrated strip needle pole 7 are made according to the center distance dimension of the honeycomb dust collecting plate 3. After assembly, the two integrated needle poles are parallel to each other, and then the total needle pole plate is connected by the insulator 4 On the fixed plate 2, artificially adjust the positions of the needle points of the two integrated strip needle poles 6 and 7 in the center of the aluminum honeycomb dust collecting plate 3. The purpose of doing this is to make the needle point discharge uniform and impro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com