Aluminum plate cutting device

A technology for cutting equipment and aluminum plates, applied in metal processing equipment, clamping, supporting and other directions, can solve the problems affecting the later processing of aluminum plates, low efficiency, and high labor intensity of workers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

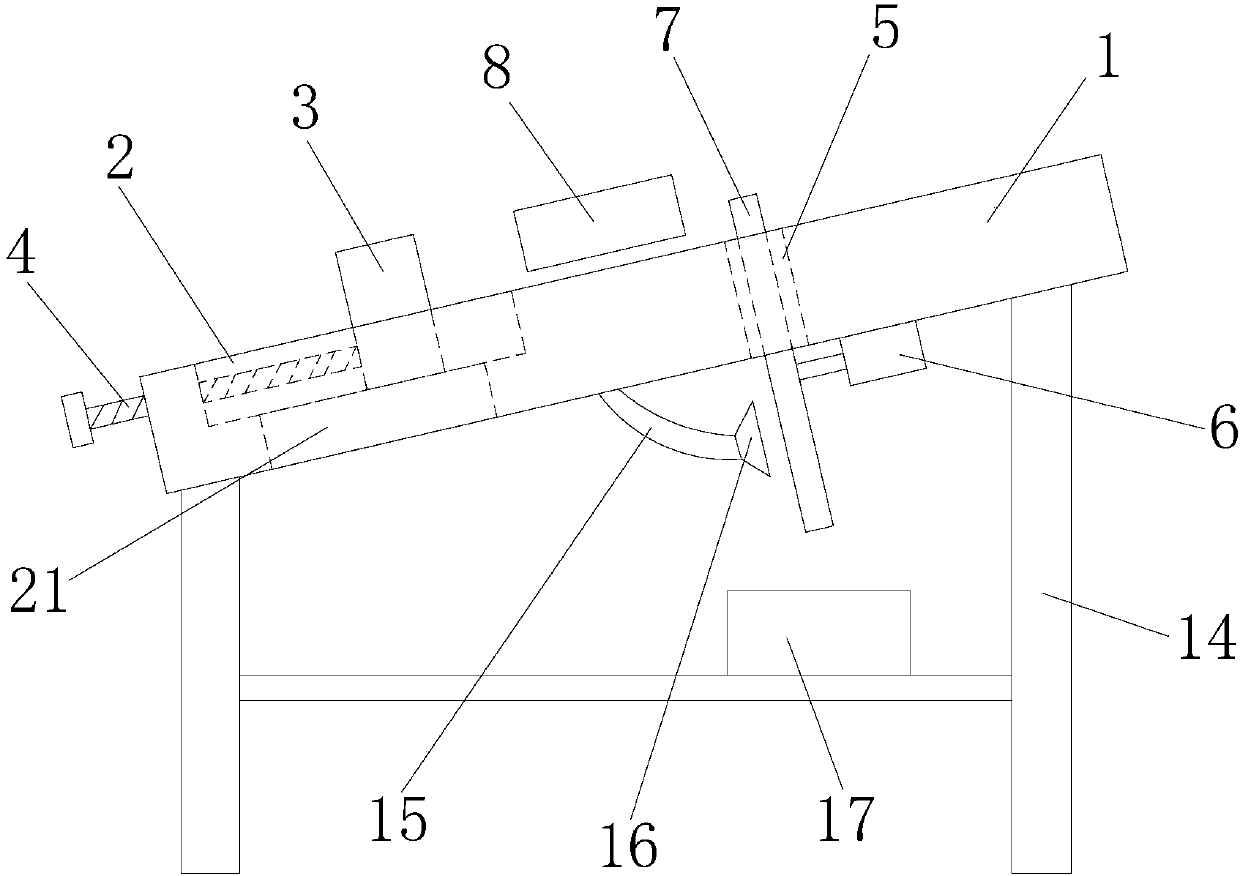

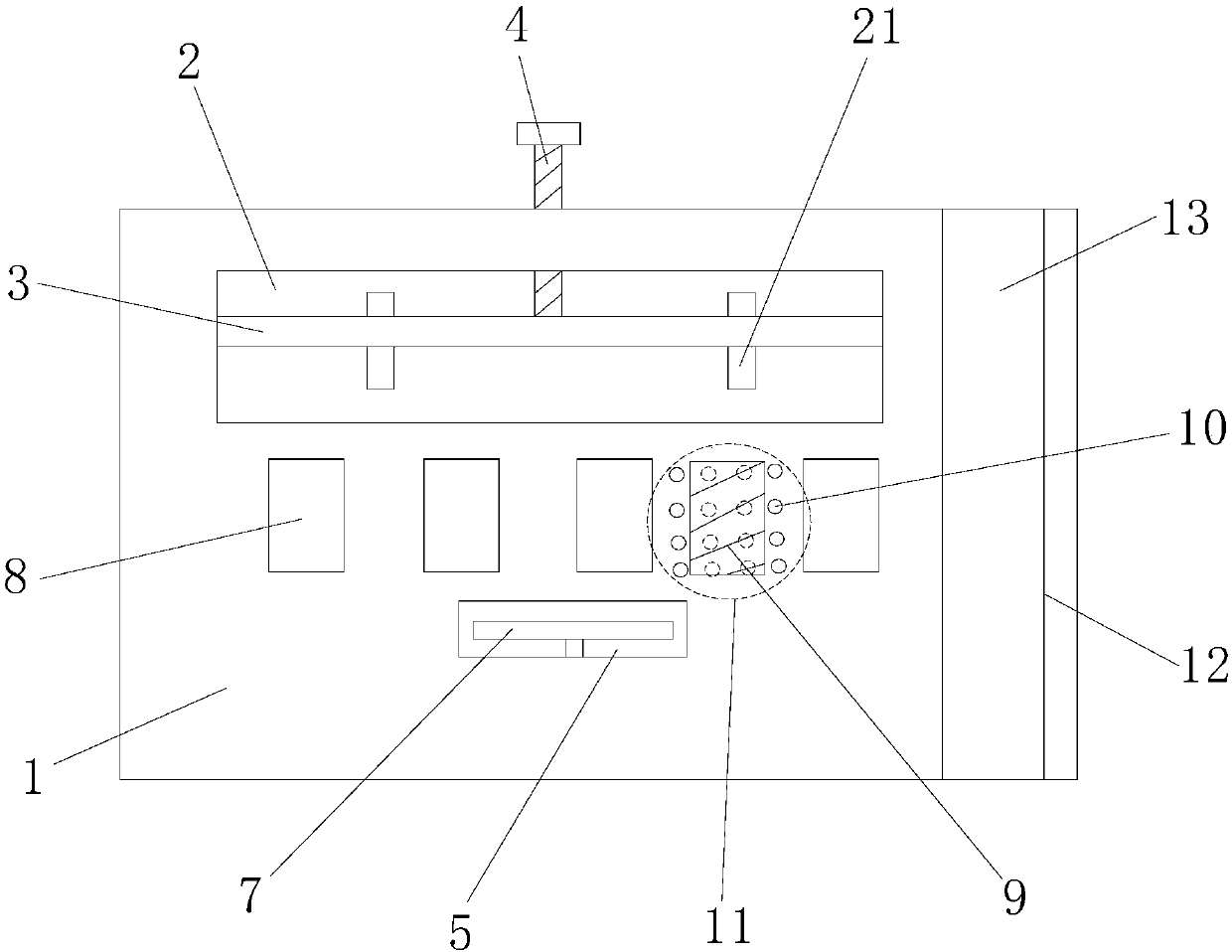

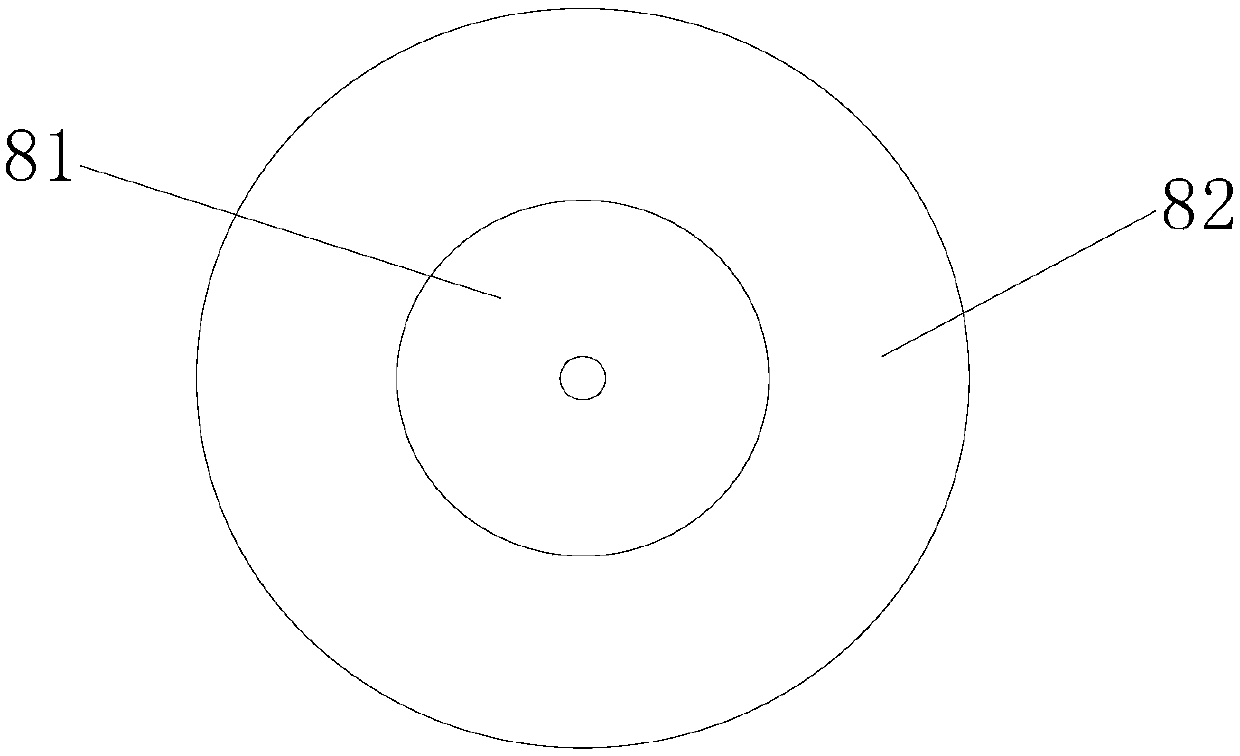

[0019] refer to figure 1 , 2 , 3, a kind of aluminum plate cutting equipment of the present invention, comprises workbench 1, chute 2, slider 3, adjusting bolt 4, cutting edge 5, motor 6, cutting knife 7, conveying roller 8, brush roller 9, dust hole 10. Dust suction pump 11, discharge chute 12, conveyor belt 13, support legs 14, metal hose 15, water spray nozzle 16 and water tank 17, the workbench 1 is arranged obliquely, and the horizontal height of the left end of the workbench 1 Lower than the level of the right end, the upper part of the workbench 1 is provided with a chute 2 along the width direction, and a slider 3 is slid inside the chute 2, and the left end of the workbench 1 is threadedly connected with an adjusting bolt 4, The drilling end of the adjusting bolt 4 stretches into the chute 2 and is rotationally connected with the left side of the slider 3. The upper part of the workbench 1 is located on the right side of the chute 2 and has a cutting edge 5. The cutt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com