Grinding wheel

a technology of rotating wheels and workpieces, which is applied in the direction of gear teeth, grinding devices, gear teeth, etc., can solve the problems of edge re-profiles that may have to be worn down, and achieve the effects of reducing grooving on the surface of workpieces, reducing grooving on workpieces, and preferably eliminating grooving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

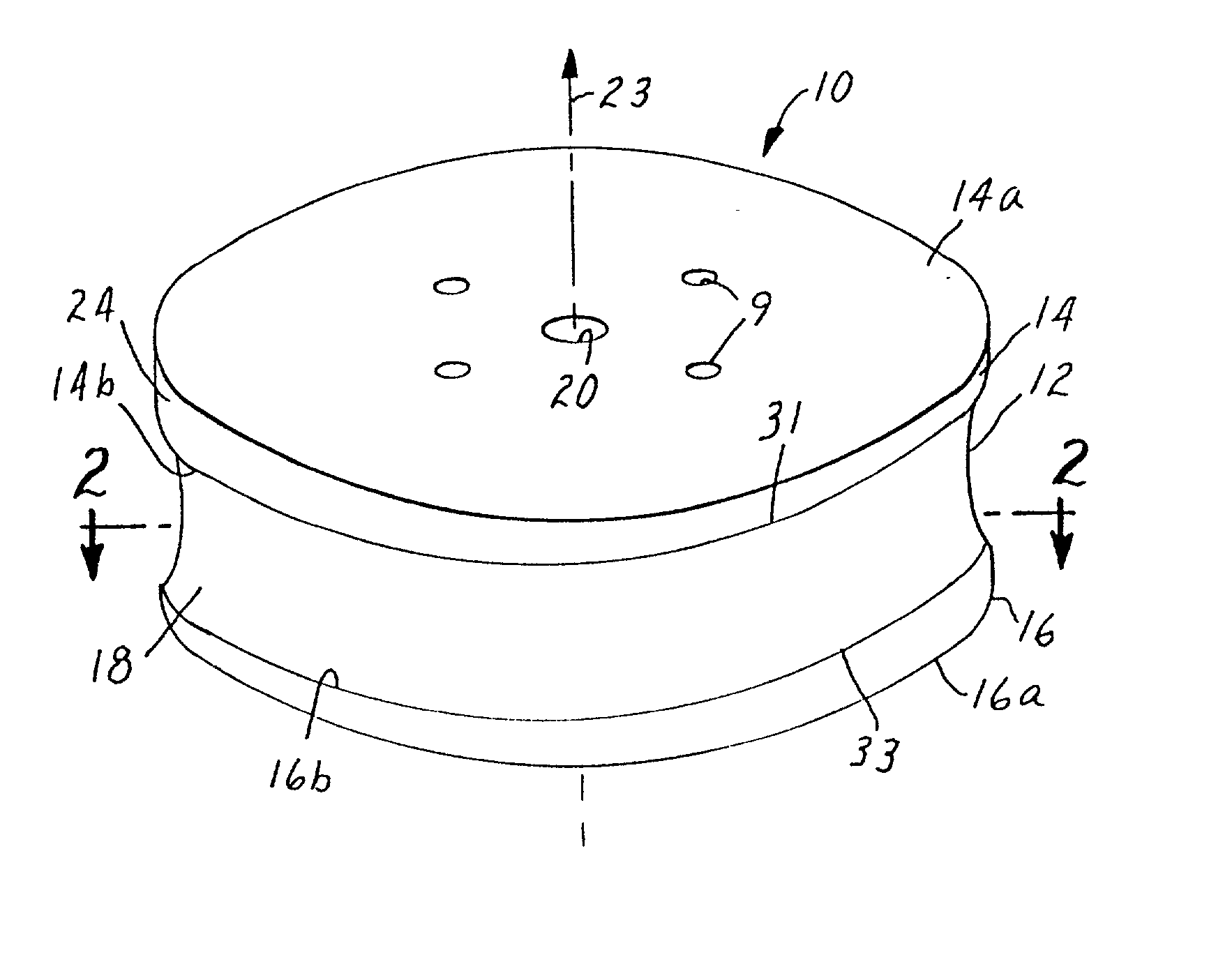

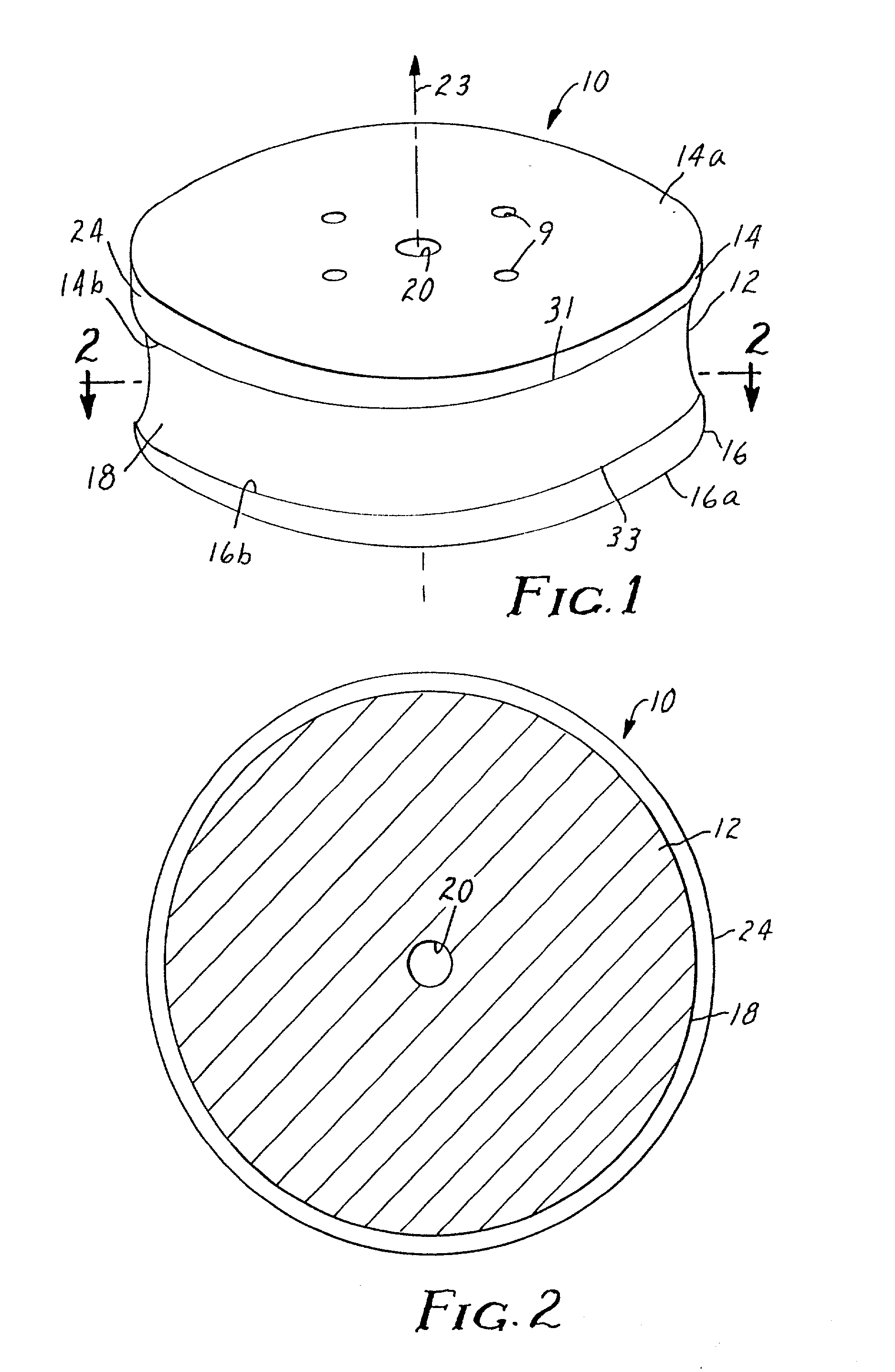

[0100] Referring now to FIG. 23 an adhesively bonded abrasive grinding wheel is shown. Grinding wheel 710 includes first support plate 714 (having inner major surface 714a and outer major surface 714b), second support plate 716 (having inner major surface 716a and outer major surface 716b), metal bond abrasive layer 712 (having first major surface 712a and second major surface 712b), first adhesive layer 715, and second adhesive layer 717. Metal bond abrasive layer 712 is a single (i.e., continuous) mass of metal bond abrasive and is interposed between first adhesive layer 715 and second adhesive layer 717. First adhesive layer 715 bonds the first major surface 712a of abrasive layer 712 to the inner major surface 714a of first support plate 714. Likewise, second adhesive layer 717 bonds the second major surface 712b of abrasive layer 712 to the inner major surface 716a of second support plate 716. Grinding wheel 710 is generally cylindrical and has bore 720 passing through a top an...

second embodiment

[0101] Referring now to FIG. 24 an adhesively bonded grinding wheel of the present invention is shown. Grinding wheel 810 includes first support plate 814 (having inner major surface 814a and outer major surface 814b), second support plate 816 (having inner major surface 816a and outer major surface 816b), metal bond abrasive layer 812, first adhesive layer 815, and second adhesive layer 817. Like wheel 710, wheel 810 via bore 820 and optional mounting holes 809 can be mounted on a rotatable shaft (not shown) and rotated about axis of rotation 823. Metal bond abrasive layer 812 is made up of a plurality of discrete metal bond abrasive segments 813 which are circumferentially spaced about the perimeter of wheel 810. The abrasive segments 813 each have first major surface 813a and second major surface 813b. The metal bond abrasive segments 813 are interposed between first adhesive layer 815 and second adhesive layer 817. First adhesive layer 815 bonds the first major surfaces 813a of ...

third embodiment

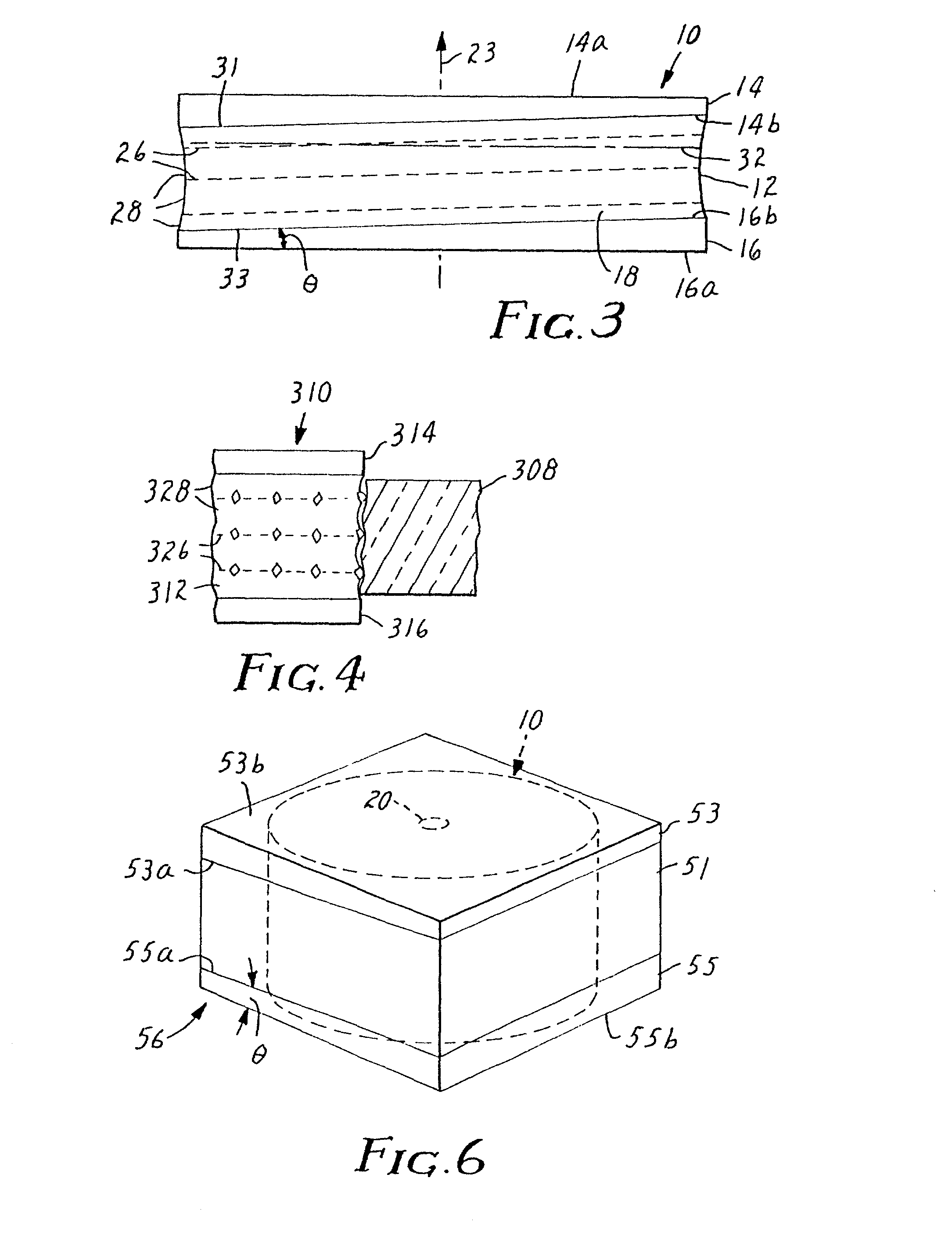

[0102] Referring now to FIGS. 25a and 25b, an adhesively bonded grinding wheel of the present invention is shown. Grinding wheel 910 includes first support plate 914 (having inner major surface 914a and outer major surface 914b), second support plate 916 (having inner major surface 916a and outer major surface 916b), abrasive layer 912, first adhesive layer 915, and second adhesive layer 917. Like wheel 710, wheel 910 via bore 920 and optional mounting holes 909 can be mounted on a rotatable shaft (not shown) and rotated about axis of rotation 923. As shown in FIG. 25b, first support plate 914 includes axially extending surface 930. Second support plate 916 has inner circular opening 922 which mates with first support plate 914 over axially extending surface 930. Abrasive layer 912 is made up of a plurality of discrete metal bond abrasive segments 913 which are circumferentially spaced about the perimeter of grinding wheel 910. The abrasive segments 913 each have a first major surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com