Gas sealing experimental device and method

An experimental device and gas sealing technology, which can be applied to electromagnetic measurement devices, liquid/vacuum measurement for liquid tightness, and measurement of fluid acceleration and deceleration rates. Affect the sensitivity of the sensor, the error of the measurement result, etc., to achieve the effect of simple and easy measurement method, high measurement accuracy and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

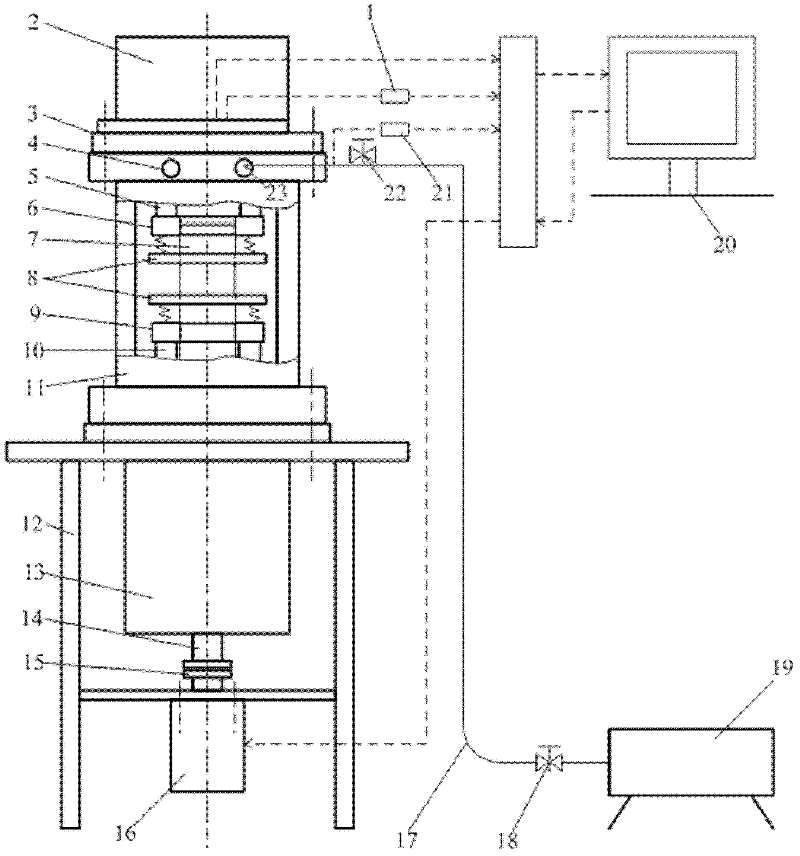

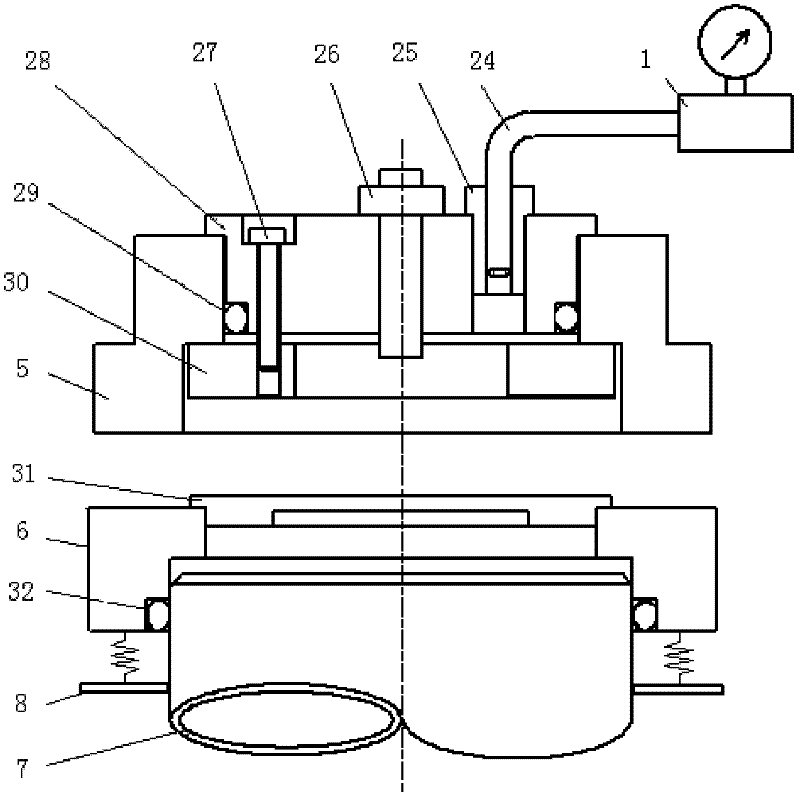

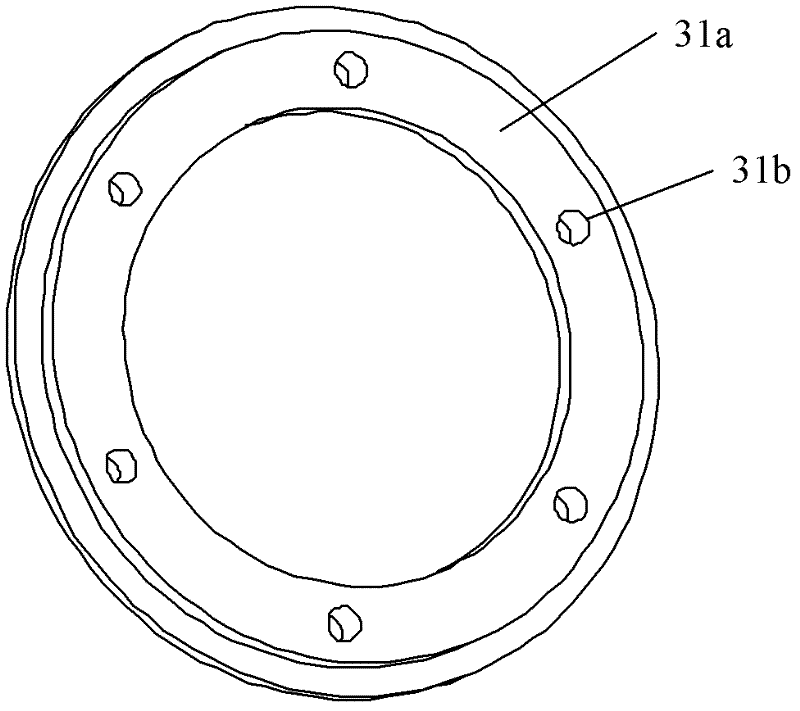

[0031] refer to figure 1 , figure 2 , image 3 and Figure 4 , the gas-tight experimental device of the present invention includes a sealed chamber 11, a drive system, a gas supply circuit and a test system, and is characterized in that the sealed chamber 11 is vertically fixed on the bracket 12 by screws, and the sealed chamber 11 includes a The upper part of the experimental seal and the auxiliary seal located at the lower part of the sealing chamber, the experimental seal dynamic ring 6 and the auxiliary seal dynamic ring 9 are installed on the dynamic ring seat 8, and the dynamic ring seat 8 is fixed on the shaft sleeve 7 by set screws, and the experimental seal An O-shaped sealing ring 32 is installed between the moving ring 6 and the shaft sleeve 7. The experimental sealing static ring 5 is connected with the end cover 3 through pins, and the end cover 3 is connected with the sealing chamber 11 through screws. The auxiliary sealing static ring 10 Connected together w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com