A metal creep forming die

A mold and metal technology, applied in the field of metal sheet creep deformation mold, can solve the problems of high mold processing cost, long design and manufacturing cycle, etc., to reduce the cost of mold trial and avoid height errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

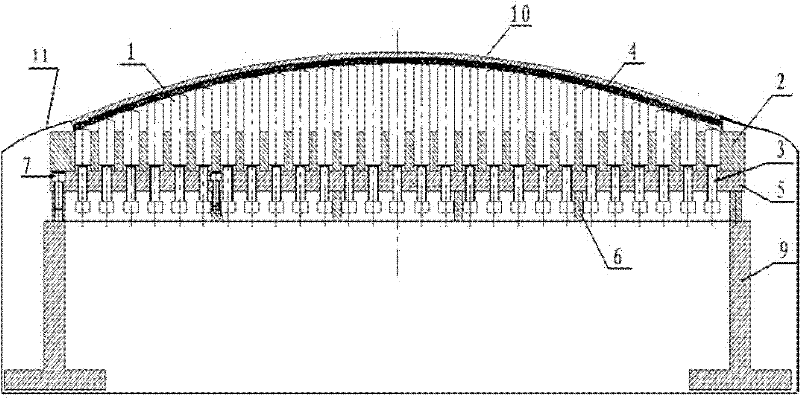

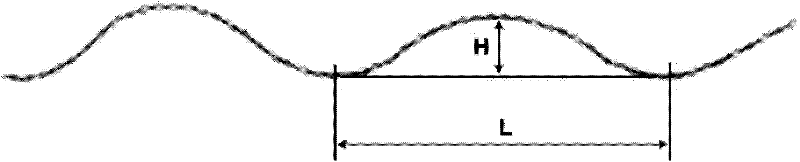

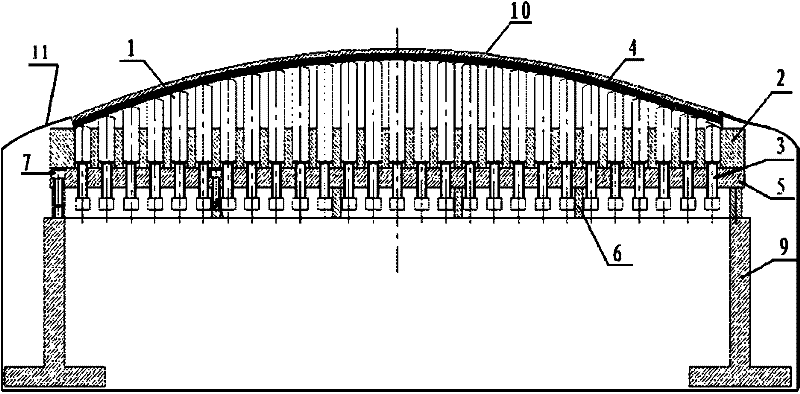

[0025] The plane size of the mold is B(400mm)×L(800mm), the ejector pin 1 has a diameter of 10mm, the two ends are hemispherical surfaces with a diameter of 10mm, the length is 50mm, and the distance between adjacent ejector pins 1 is 10mm; the thickness of the ejector pin fixing plate 2 is 20mm ; Each ejector rod 1 is equipped with a corresponding screw 3; the thickness of the screw fixing plate 5 is 50mm; the height of the rib 6 is 20mm; Taking the plane of ejector pin fixing plate 2 as a reference, the height array of ejector pin 1 is adjusted according to the radius of curvature in the L direction of 3000 mm, and the 0.5 mm thick 7075 aluminum alloy plate after solution quenching is used as the creep forming blank, and the mold and forming blank are used After the plastic bag 11 is sealed, vacuumize it, then place it in a normal-pressure heating furnace, and heat it at a rate of 150° C. for 16 hours. During the heating process, continue to vacuumize the sealed bag. Unload ...

Embodiment 2

[0027]The plane size of the mold is B(1600mm)×L(3900mm), the diameter of ejector pin 1 is 50mm, and the two ends are hemispherical surfaces with a diameter of 50mm, and the distance between adjacent ejector pins 1 is 250mm; the thickness of ejector pin fixing plate 2 is 120mm; The ejector rods 1 are equipped with corresponding screw rods 3; the thickness of the screw rod fixing plate 5 is 120mm; the height of the reinforcing rib 6 is 100mm; Taking the plane of the ejector pin fixing plate 2 as a reference, the height array of the ejector pin 1 is adjusted according to the radius of curvature in the L direction of 5000 mm, and the 100 mm thick 7075 aluminum alloy plate after solution quenching is used as the creep forming blank, and the mold and the forming blank are made of plastic After the bag 11 is sealed, vacuumize it, then place it in an 8MPa pressure tank, and heat it at 150°C for 16 hours, and continue to vacuumize the sealed bag during the heating process. Unload after...

Embodiment 3

[0029] Die plane size is B(400mm)×L(800mm), ejector pin 1 has a diameter of 20mm, both ends are hemispherical surfaces with a diameter of 20mm, the distance between adjacent ejector pins 1 is 50mm; the thickness of ejector pin fixing plate 2 is 20mm; each The ejector rods 1 are equipped with corresponding screw rods 3; the thickness of the screw fixing plate 5 is 50mm; the height of the reinforcing rib 6 is 50mm; Taking the plane of the ejector pin fixing plate 2 as a reference, adjust the height array of the ejector pin 1 according to the radius of curvature in the L direction of 3000mm and the radius of curvature in the B direction of 1500mm, and use a 10mm thick 2024 aluminum alloy plate after solution quenching as the creep forming blank. Seal the mold and the forming blank with a plastic bag 11 and then vacuumize it, then place it in a 4MPa pressure tank and heat it at 185°C for 24 hours, and continue to vacuumize the sealed bag during the heating process. Unload after he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com