Junction surface contact area and rigidity confirming method based on surface fitting

A contact area and surface fitting technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problem of limiting the size of the calculation area and calculation efficiency, without considering the geometric shape, that is, the waviness and the contact stiffness of the combined surface Affecting the law, divorced from reality and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention is described in detail below in conjunction with accompanying drawing:

[0049] A method for determining the contact area and stiffness of a joint surface based on surface fitting, comprising the following steps:

[0050] 1) Measurement of real shape and function representation

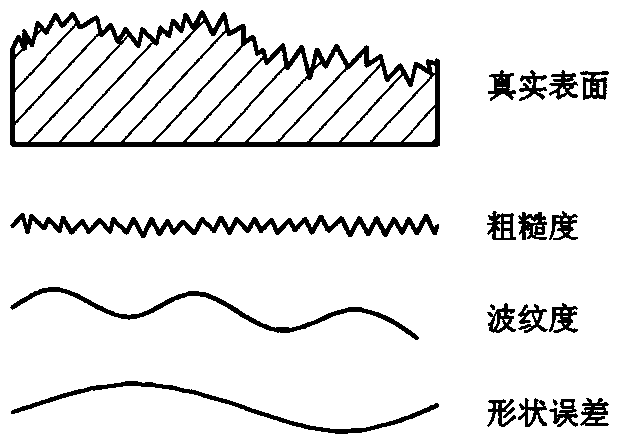

[0051] 1.1) Classification of joint surface morphology: such as figure 1 As shown, the mechanical bonding surface is divided into three levels of roughness, waviness, and shape error according to the wavelength from small to large. The peak-to-peak spacing is less than 1mm. Convex body, and assuming that the shape of the micro-convex body is the same; the surface undulation with the distance between the peaks within the range of 1mm to 10mm is regarded as waviness; the surface undulation with the distance between the peaks exceeding 10mm is regarded as the surface shape error deal with;

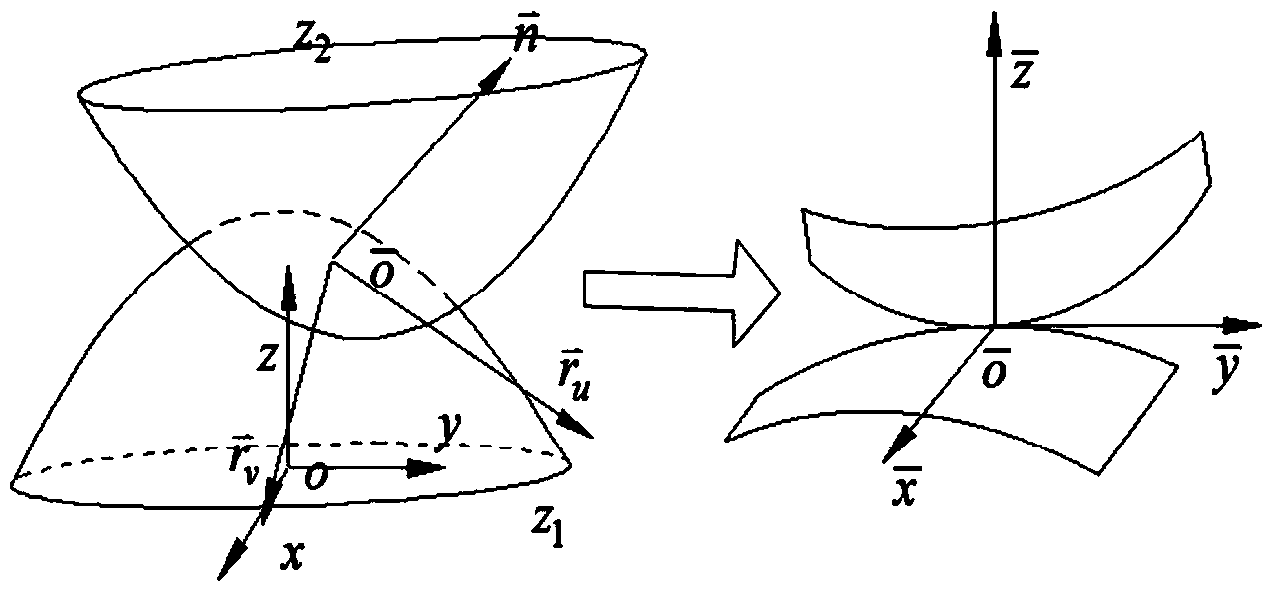

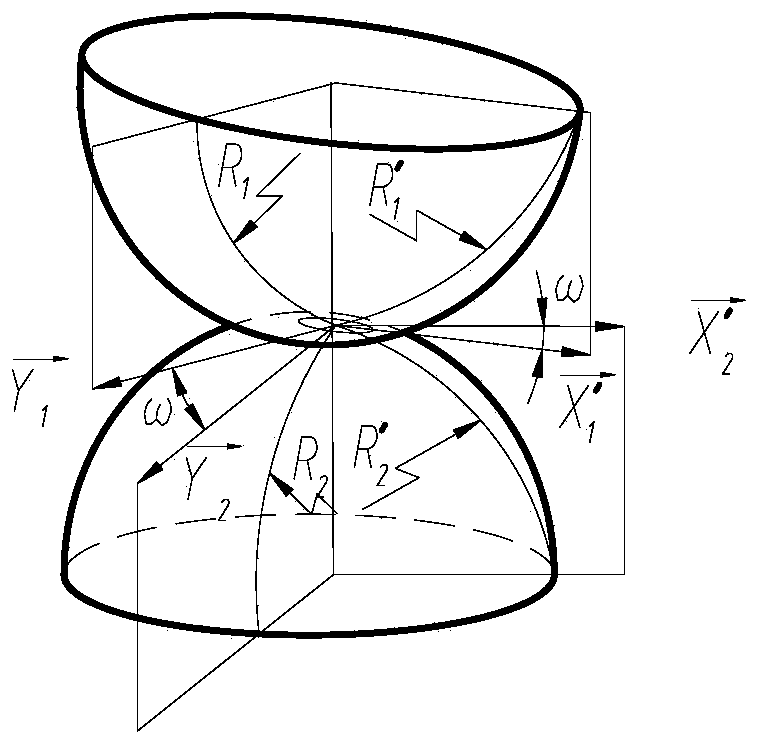

[0052] 1.2) Asperity function fitting: use confocal microscope to observe the aspe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com