Measuring apparatus for measuring bearing and its part surface appearance

A surface topography and measuring instrument technology, applied in the field of measurement, can solve the problems that the linearity of the guide rail cannot truly meet the measurement requirements, the Z direction cannot be measured and positioned, and the high-precision measurement cannot be truly achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

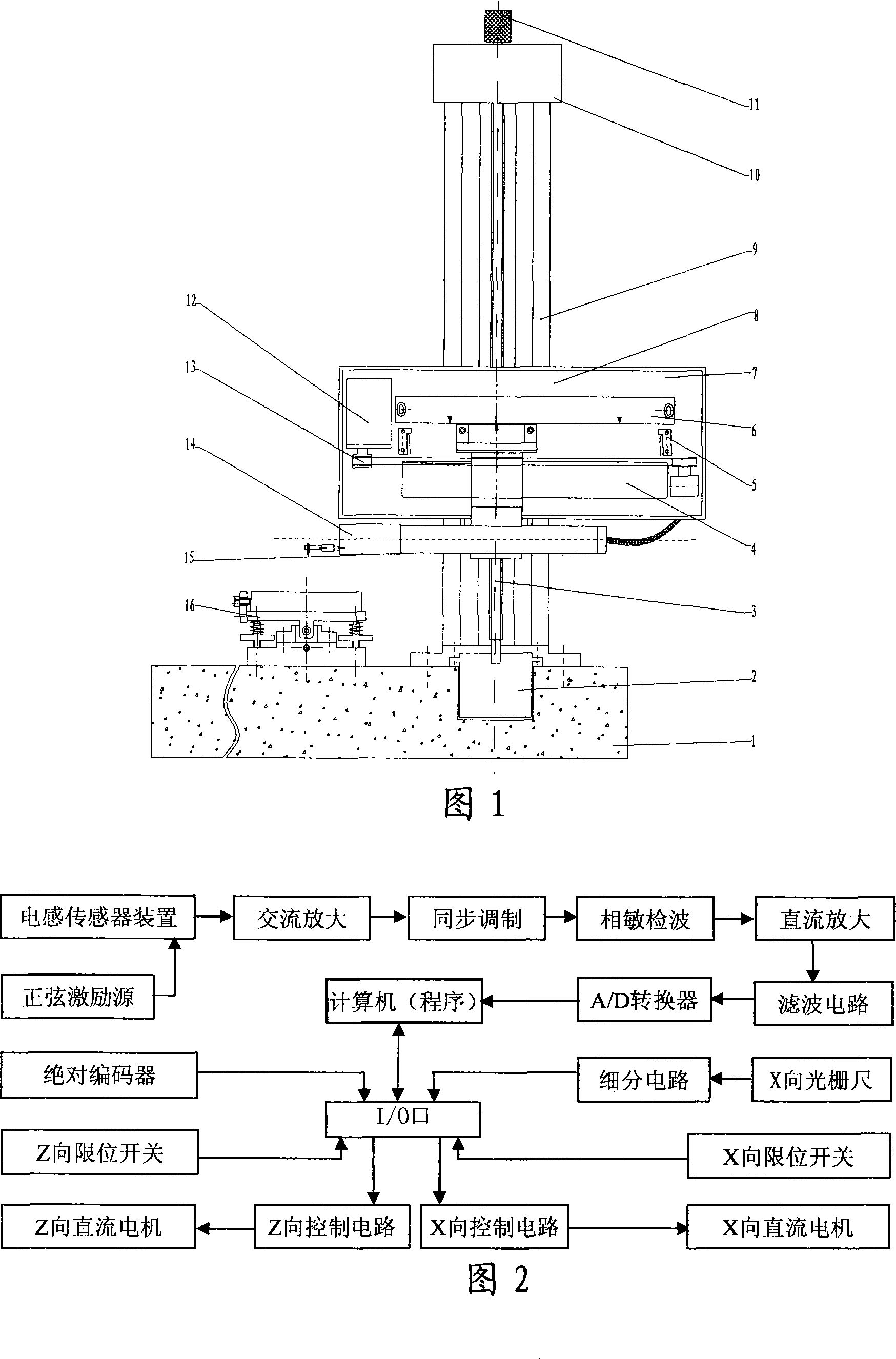

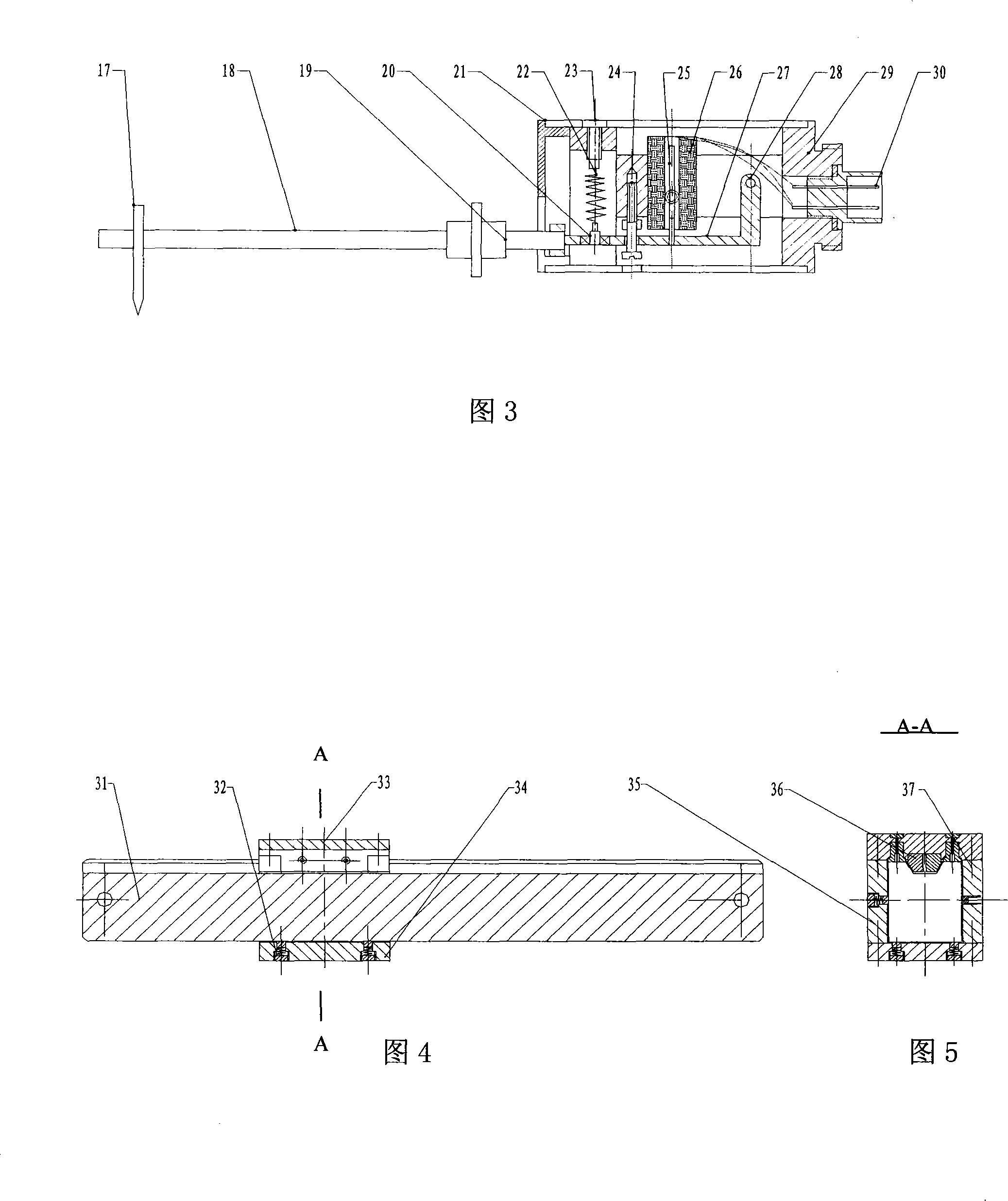

[0025] As shown in Figures 1 and 2: the column guide rail (9) is vertically installed on one end of the measurement base (1), the sensor drive box (8) is installed on the column guide rail (9), and the multi-dimensional workbench (16) is installed on the measurement base on the base (1), it can move horizontally left and right; the diamond stylus (17) is inserted into the inductance sensor device (14) at the lower end of one side of the sensor drive box (8), facing the multi-dimensional workbench (16), it can be moved on the X-direction motor Driven by (12), it moves horizontally along the X-direction rail (4) through the X-direction pulley and toothed belt (13). The moving distance is collected by the X-direction signal acquisition grating (6) and the signal is subdivided and synchronized. into the computer, and the sensor is limited by the X-direction limit switch (5) during the left and right movement; the sensor drive box (8) is installed on the lead screw nut in the ball s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com