Cylinder cylindrical surface groove line precision detection device and method based on projection trajectory recovery

A technology of projection trajectory and accuracy detection, applied in measurement devices, mechanical measurement devices, and mechanical devices, etc., can solve the problems of unstable test accuracy, low efficiency, complicated operation, etc., and achieve simple and easy measurement data processing and adjustment speed. Fast and efficient measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below with reference to the accompanying drawings and exemplary embodiments.

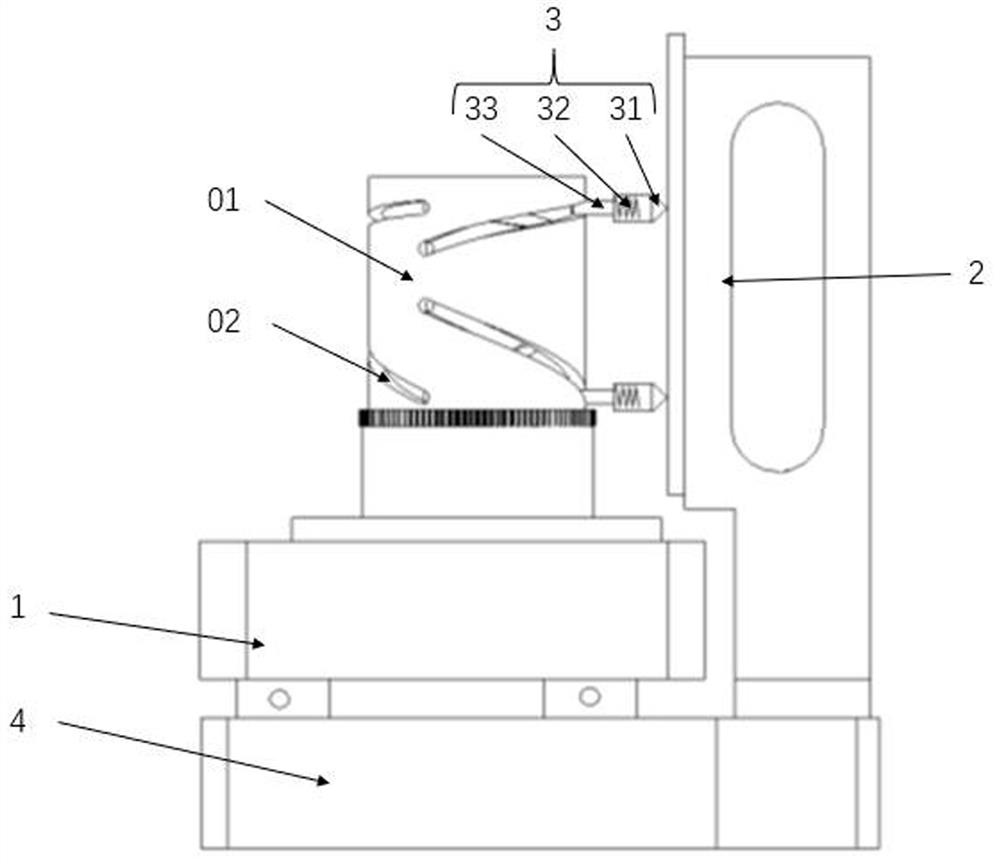

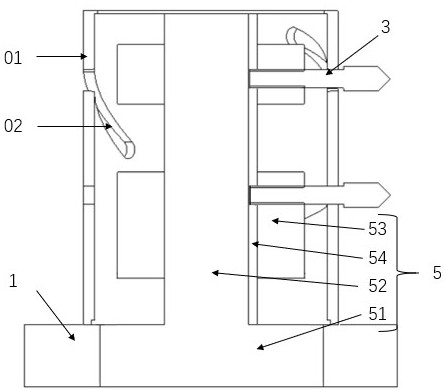

[0029] refer to figure 1 and figure 2 , a cylinder-cylindrical groove line accuracy detection device based on projection trajectory restoration, comprising an annular turntable 1 , a marking plate 2 , two marking pens 3 , a translation stage 4 and an adjustment assembly 5 .

[0030] The cylinder 01 to be inspected is a hollow structure with at least one cylindrical groove line 02 on it. The cylindrical body 01 to be inspected includes at least one equal diameter section, and each cylindrical groove line 02 is located in the same equal diameter section; in this embodiment, The cylinder 01 to be inspected is an equal diameter cylinder, and two cylindrical groove lines 02 are arranged on the cylinder 01 to be inspected.

[0031] The marking plate 2 is arranged on a fixed base on one side of the translation stage 4; the annular turntable 1 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com