Device and method for high-precision measurement of large-angle optical wedge angle

A large-angle, high-precision technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of questionable measurement accuracy, inconvenient measurement, and many devices, so as to save batch testing time, simple and fast testing methods, The effect of low device cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

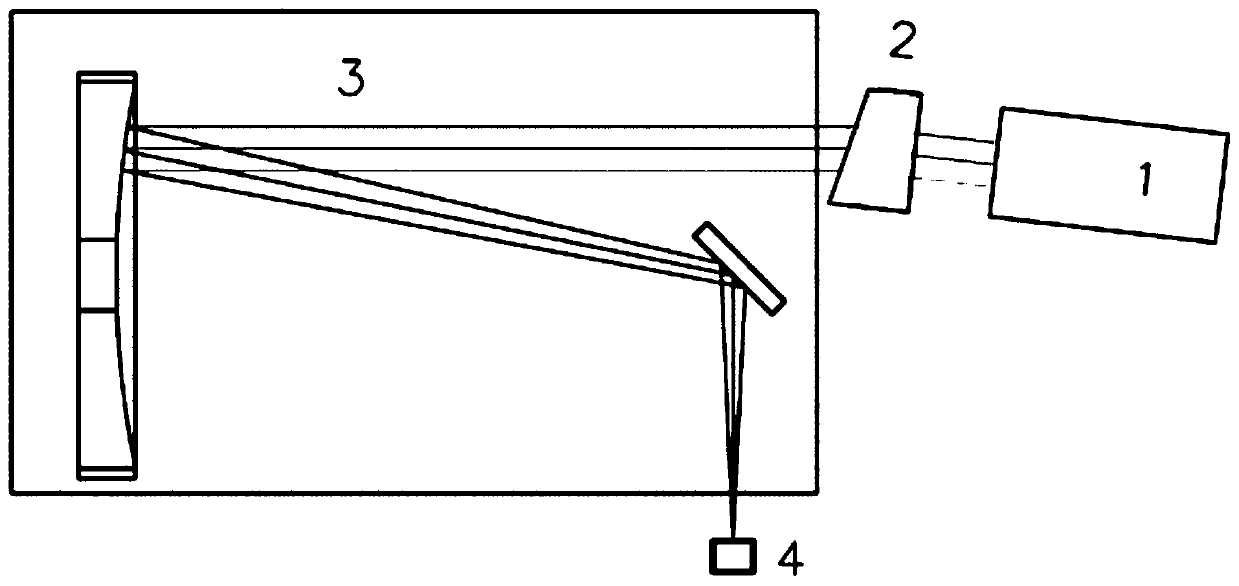

[0044] The implementation examples of the method of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0045] The main devices adopted in the present invention are described as follows:

[0046] 1. Collimated laser light source 1: The collimated laser light source 1 is composed of single-mode fiber, collimating lens and fiber laser. The fiber adopts the single-mode fiber of Thorlabs company model SM600, and its main performance parameters: the working band is 600-900nm The fiber mode field diameter is 4.6um@680nm, the cladding core diameter is 125±1um, and the cut-off wavelength is 550±50nm; the collimating lens adopts the collimating mirror of Thorlabs company model F810FC-635, and the focal length of the collimating mirror is 35.4mm. The wavelength used is 635nm; the laser adopts the laser diode of Thorlabs company model LPS-PM635-FC, and the laser wavelength is 635nm;

[0047] 2. Optical wedge 2 with a rotating structure:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com