Magnetic leakage flux flow detection method and mfg. method of hot rolled steel plate using same

A technology of hot-rolled steel plate and flaw detection method, which is applied in the direction of material magnetic variable, electromagnetic measuring device, electric/magnetic roughness/irregularity measurement, etc., and can solve problems such as difficulty in accurately detecting defects, magnetic flux disorder, and leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

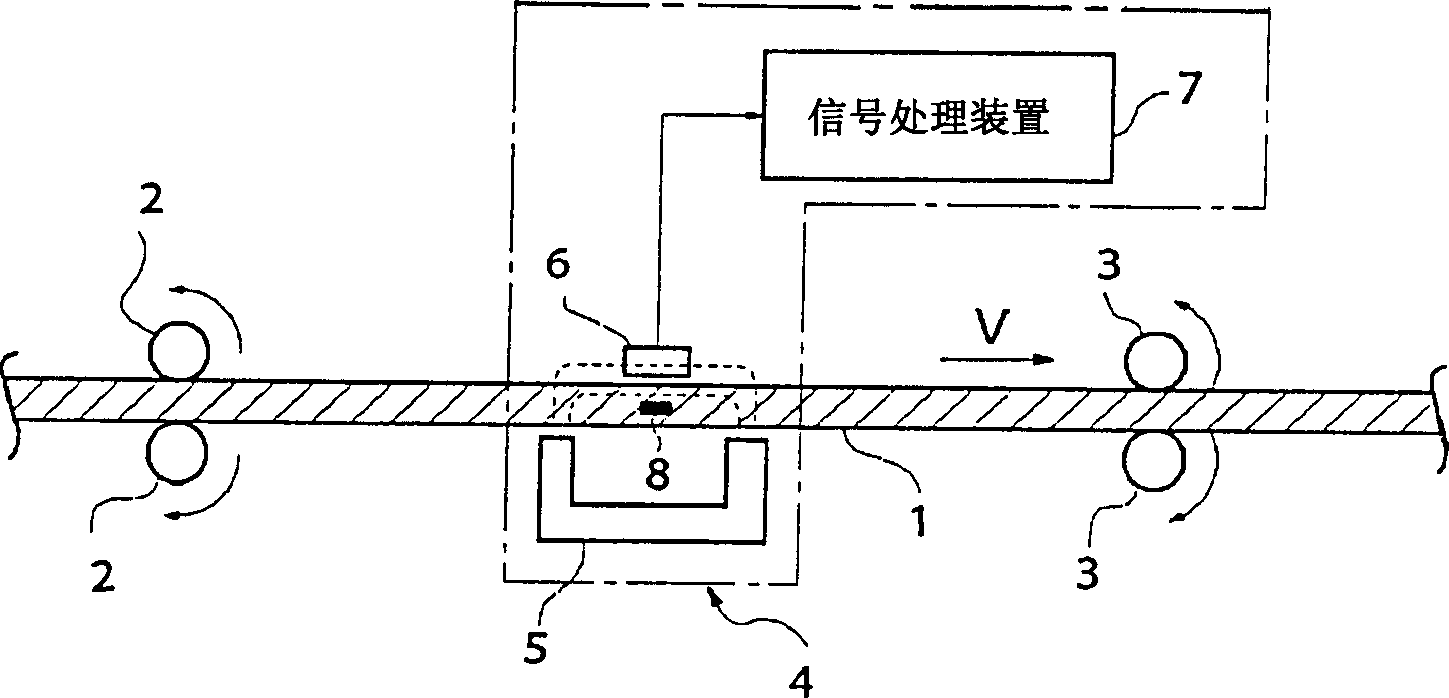

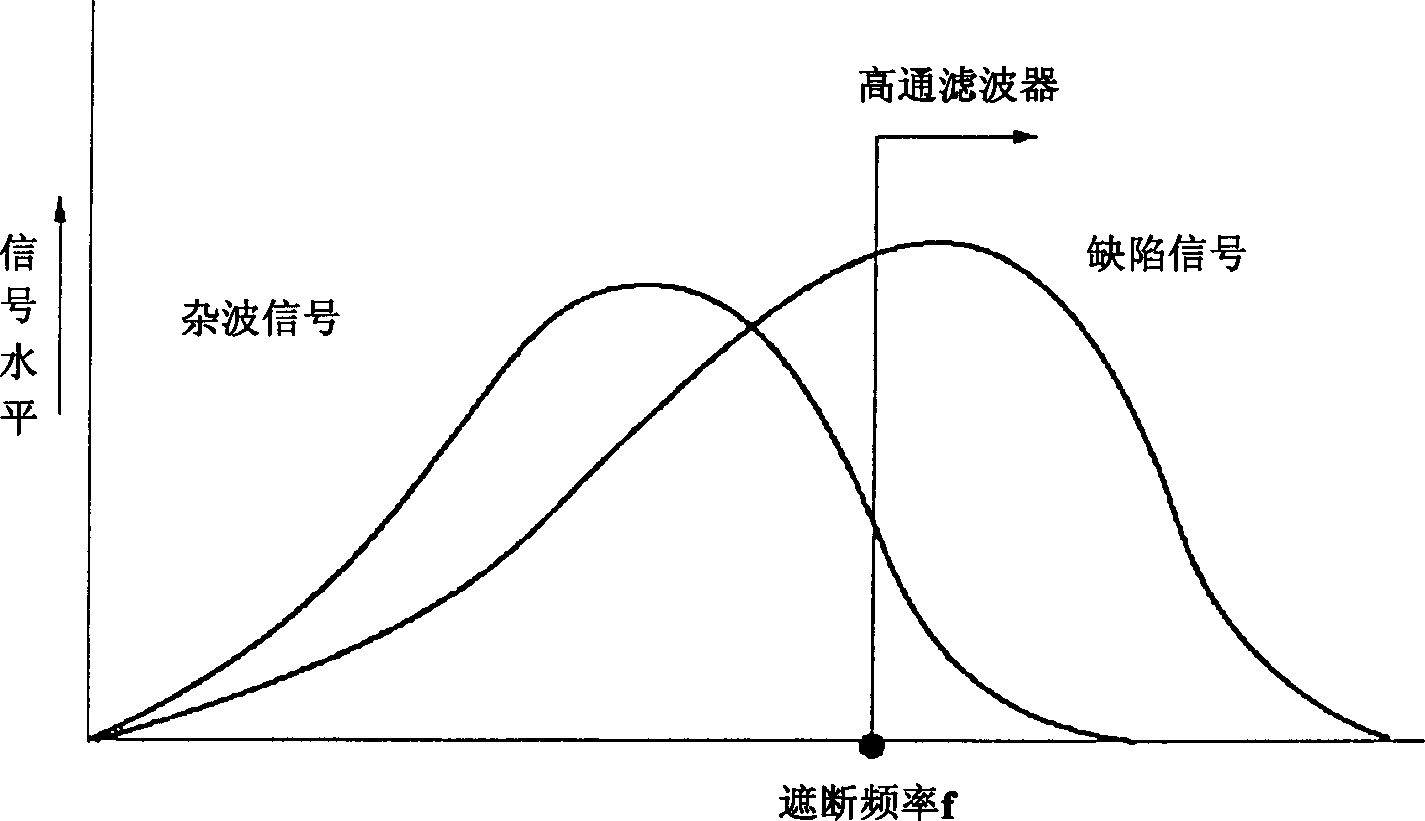

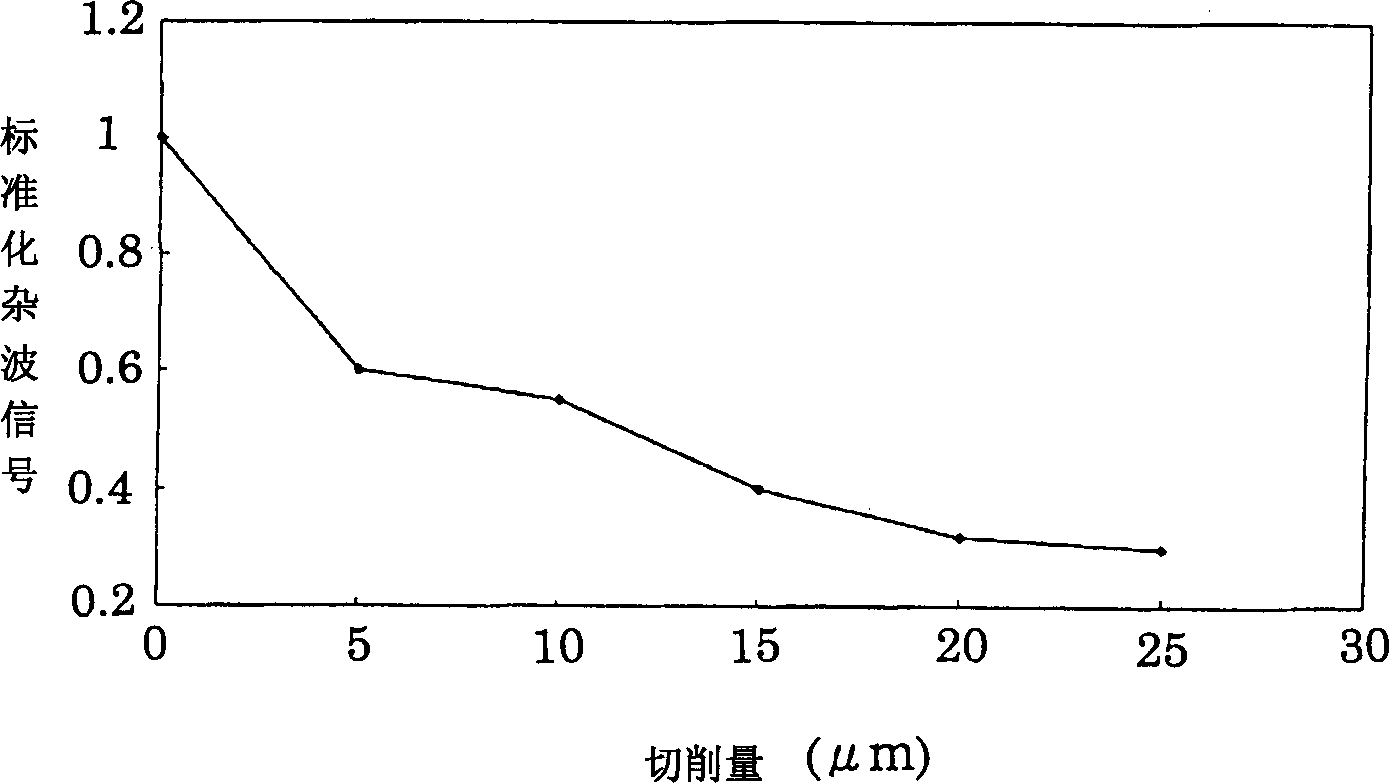

[0050] Set on the steel plate inspection line as Figure 5 In the magnetic flaw detection device shown, a steel plate 1 with a thickness of 1 mm is transferred at a speed of 100 m / min, and a saturation magnetic field strength of 2500 AT is applied to the steel plate 1 with a magnetizer 5 a (strong magnetization condition), and a magnetic field of 1000 AT is applied to the steel plate 1 with a magnetizer 5 b. Under saturation magnetization (weak magnetization condition), in the above-mentioned method, the output signal Va of strong magnetization condition is detected by magnetic probe 6a, and the output signal Vb of weak magnetization condition is detected by magnetic probe 6b. The reason for using a magnetic field of 2500AT under strong magnetization conditions and a magnetic field of 1000AT under weak magnetization conditions is that a common clutter signal is detected under the two conditions, and the change of the defect signal level is greater than the change of the clutter...

Embodiment 2

[0054] Figure 8 Another example of a magnetic flaw detection apparatus for carrying out the magnetic flux leakage flaw detection method of the present invention is shown. This device is compatible with figure 1 The magnetic pole center of the magnetizer 5 shown in the current device is different from the magnetic probe 6a in the opposite direction, but another magnetic probe 6b is provided at a position only 4mm apart from the magnetization direction. The distance L between the magnetic probes 6a and 6b was set to 0.7 mm.

[0055] like Figure 8 As shown, a magnetic flaw detection device is installed on the steel plate inspection line, and a steel plate 1 with a thickness of 1 mm is transferred at a speed of 100 m / min. A magnetic field of 3000 AT is applied by a magnetizer 5a to saturate and magnetize the steel plate 1, and a magnetic probe 6a is used to detect the strength of the corresponding example 1 The output signal Va of the magnetization condition is detected by th...

Embodiment 3

[0060] like Figure 10 As shown, using the hot-rolled coil production process with the inclusion inspection process and the process of providing defect information, a low-carbon steel hot-rolled coil with a thickness of 1.8mm and a width of 1m is produced, and the defect inspection is carried out with the oxide scale to obtain the defect position and density information. At this time, in the inclusion inspection process, use a magnetic probe installed at intervals of 5 mm in the width direction of the coil, and Figure 5 The same magnetic flaw detection device was used to detect defects under the same magnetization conditions as in Example 1.

[0061] Figure 11 It shows an example of identifying defect position information in a part of the length direction of the hot-rolled coil within 1000m. In this way, even for hot-rolled coils with scale, the plane position of the defect can be provided by marking. Furthermore, one of information such as the depth, size, and shape of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com