Heat contractibility rate measuring method for furniture thermoplastic plastic edge sealing stripes

A thermoplastic and thermal shrinkage technology, applied in the direction of material thermal expansion coefficient, etc., can solve the problems of complex test operation, complex equipment and insufficient test representativeness, etc., to achieve simple test equipment, simple measurement method, saving test cost and test. effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

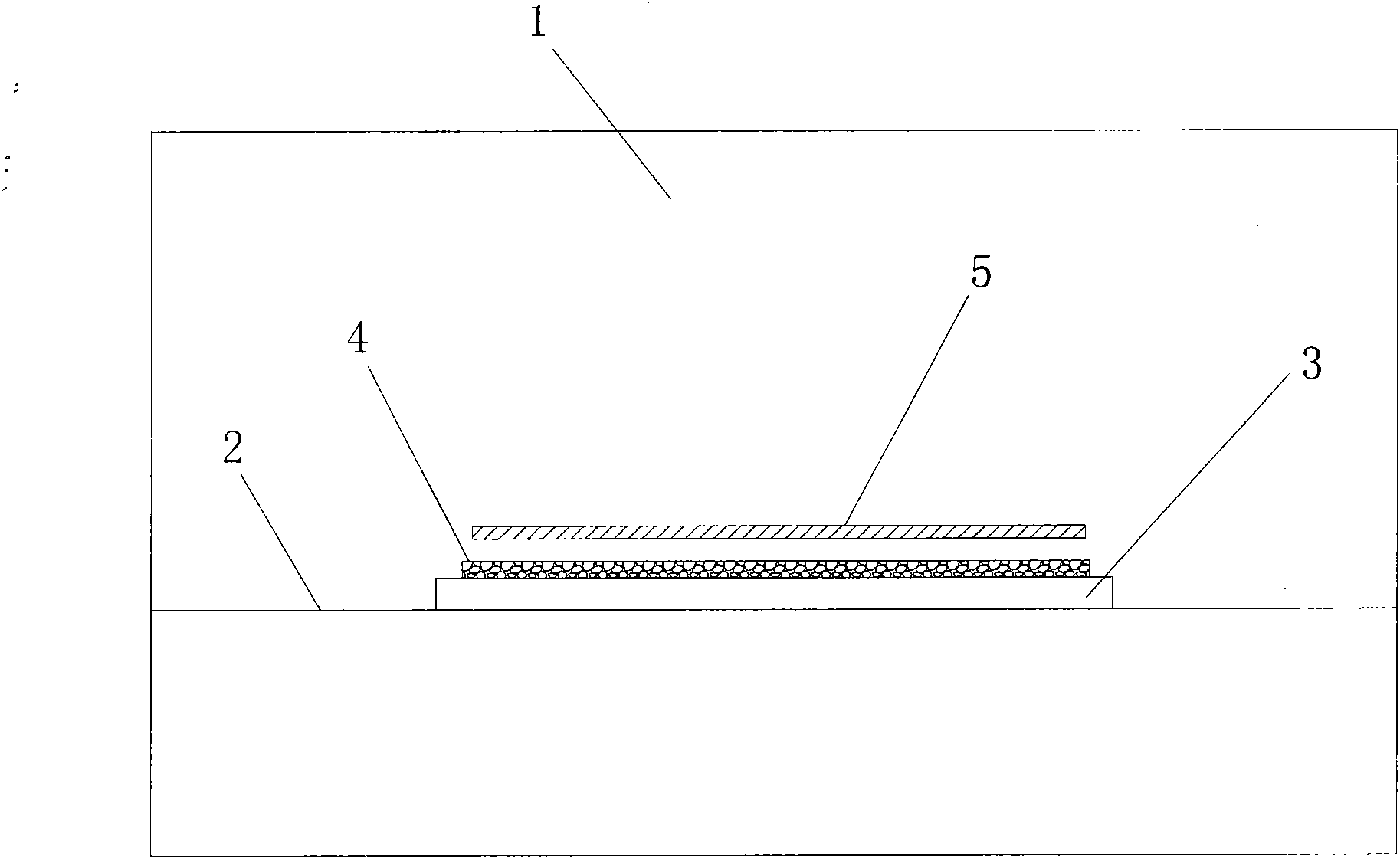

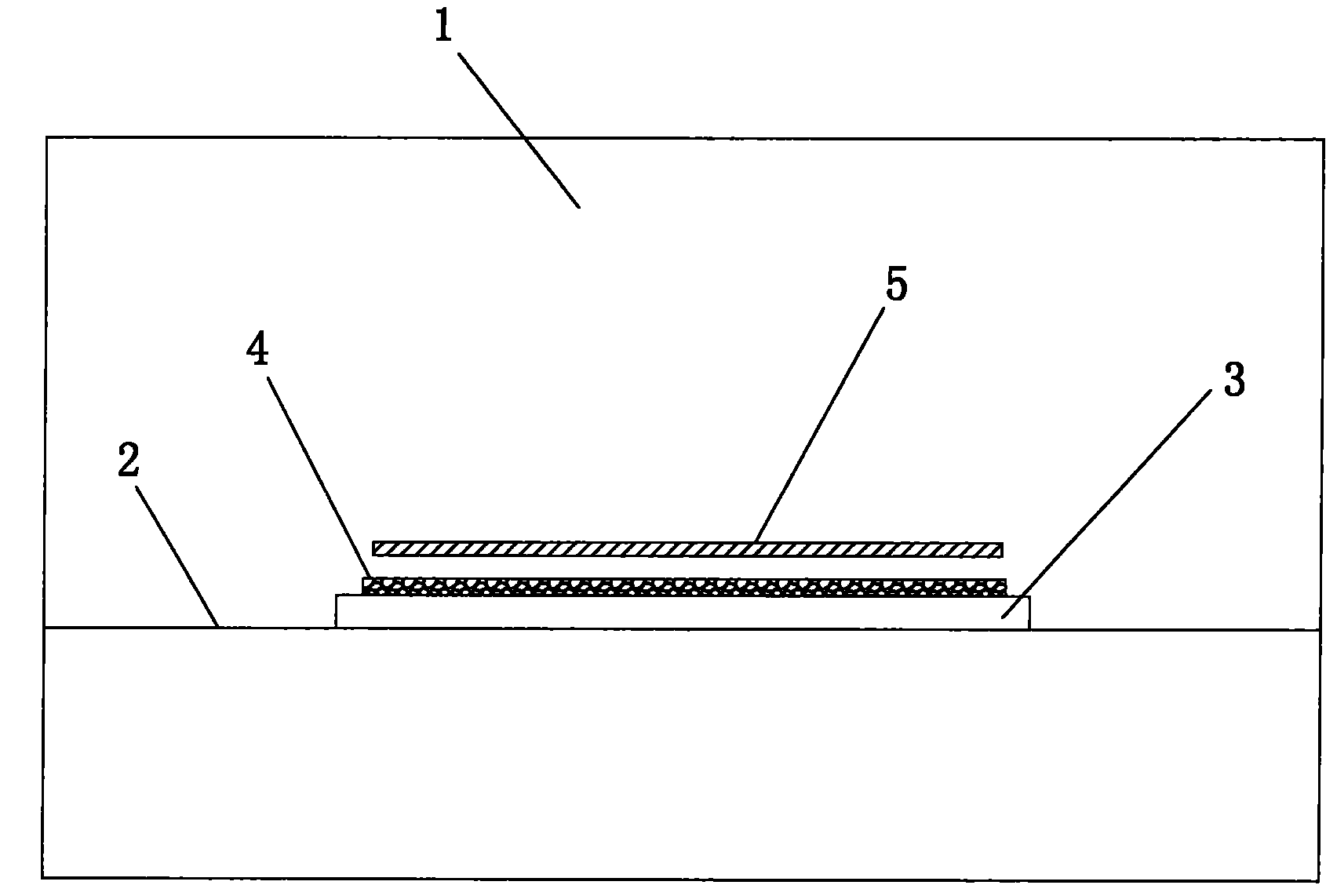

[0018] In this example, refer to figure 1 , the thermal shrinkage rate measuring method of described furniture thermoplastic edge banding, carry out according to the following steps:

[0019] 1) Prepare the circulating air oven 1, vernier caliper, test bench 2, timer (not shown), glass plate 3 and talc powder 4, and the specification of the glass plate is 300×300mm;

[0020] 2), prepare five edge banding samples 5, of course it can be 3 or 4, the length is 200mm, and the error is 0.5mm;

[0021] 3) Put the test bench into the circulating air oven 1, sprinkle talcum powder 4 on the glass plate 3, and spread it evenly, and put the glass plate 3 on the test bench 2;

[0022] 4), adjust the temperature of the circulating air oven 1 to 65°C, of course it can also be between 60-70°C, and then place the sample 5 on the talcum powder 4 on the glass plate 3;

[0023] 5) Sample 5 was kept in the circulating air oven 1 for 4 hours and then taken out, placed horizontally at room tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com