Method and device for detecting wear of tooth surface of large involute spur gear

A large-scale gear and detection method technology, applied in the direction of measuring devices, mechanical measuring devices, and mechanical devices, can solve the problems of complex operation and high cost, and achieve the effects of simple device positioning, low detection cost, and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

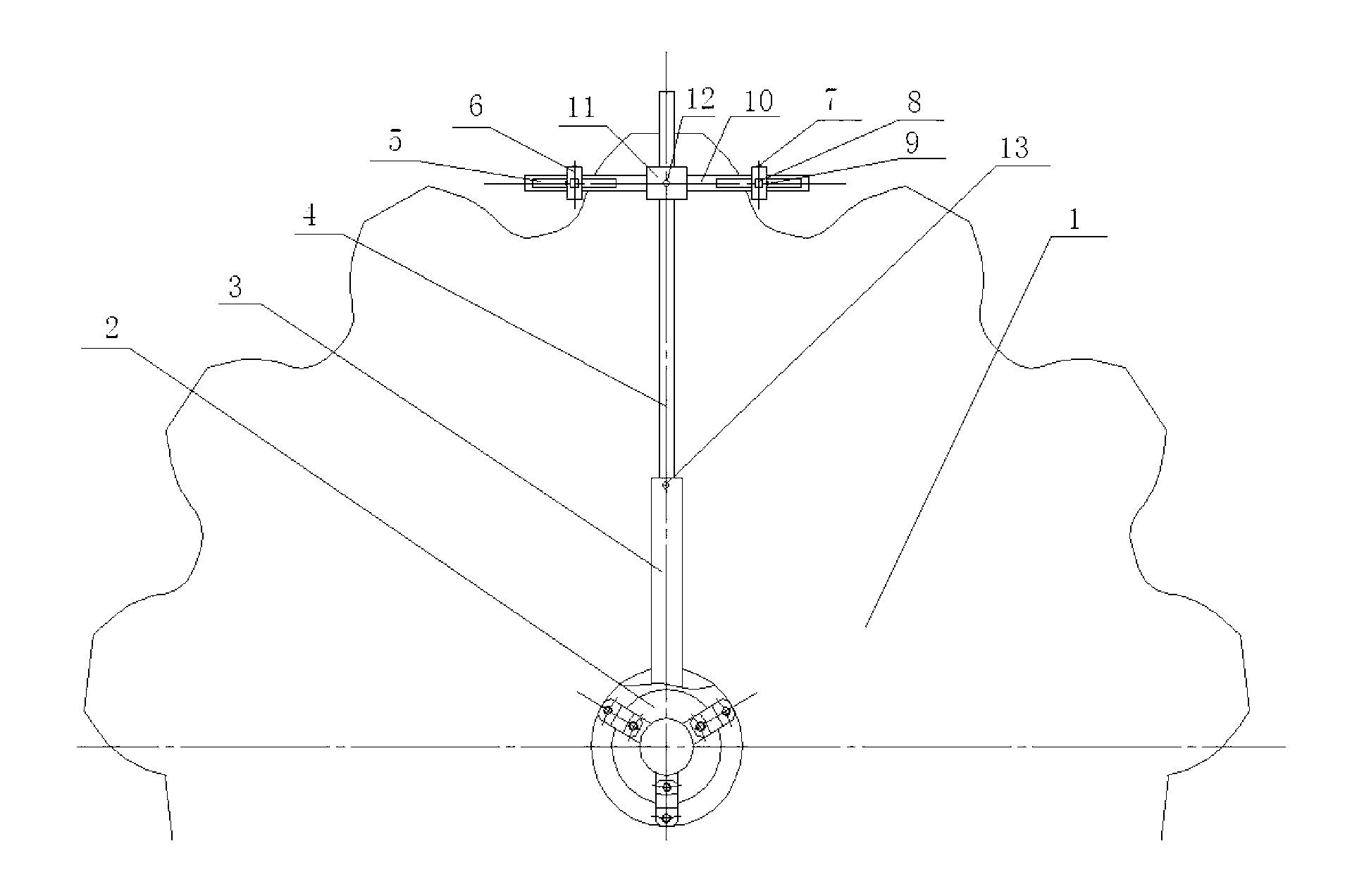

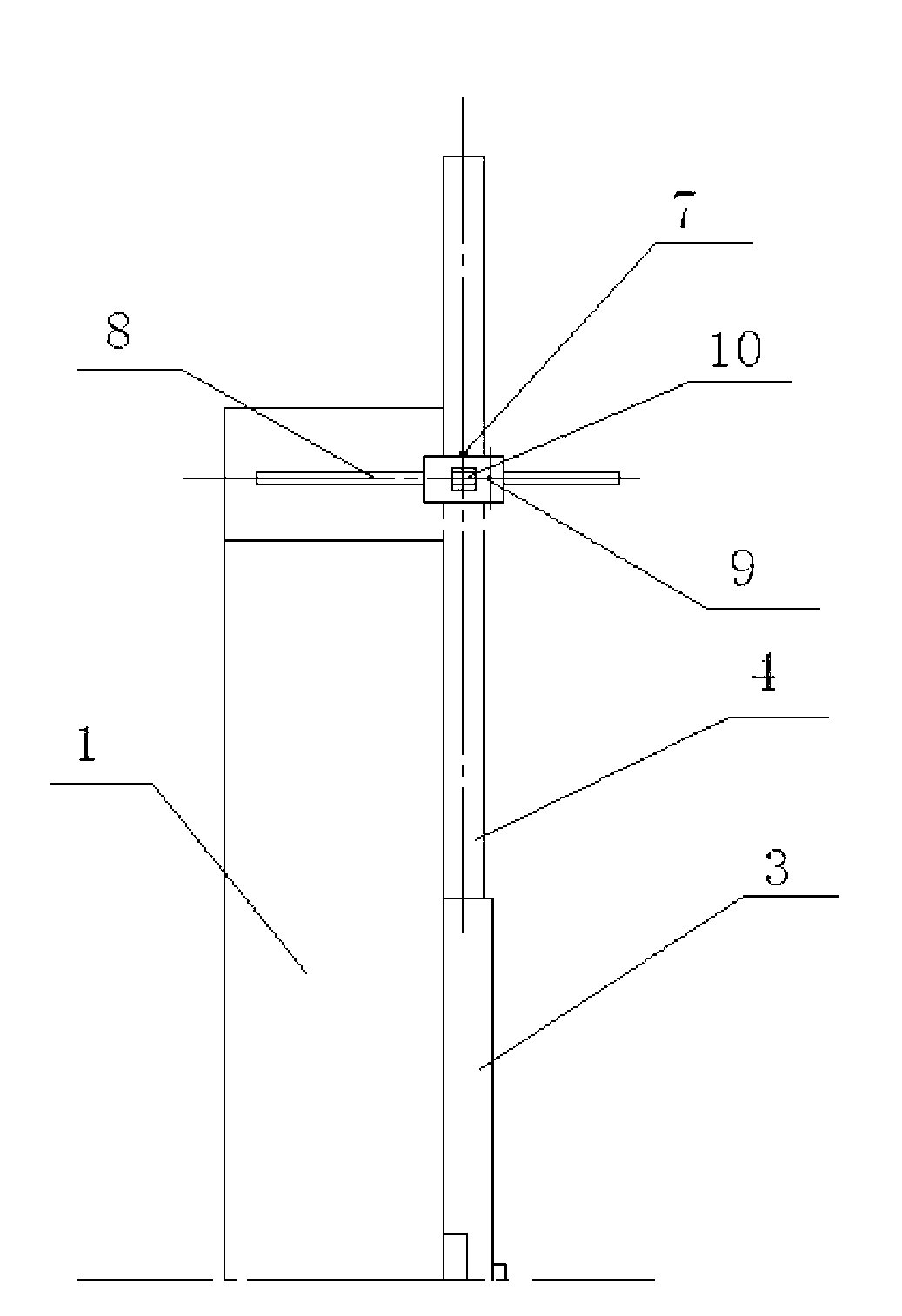

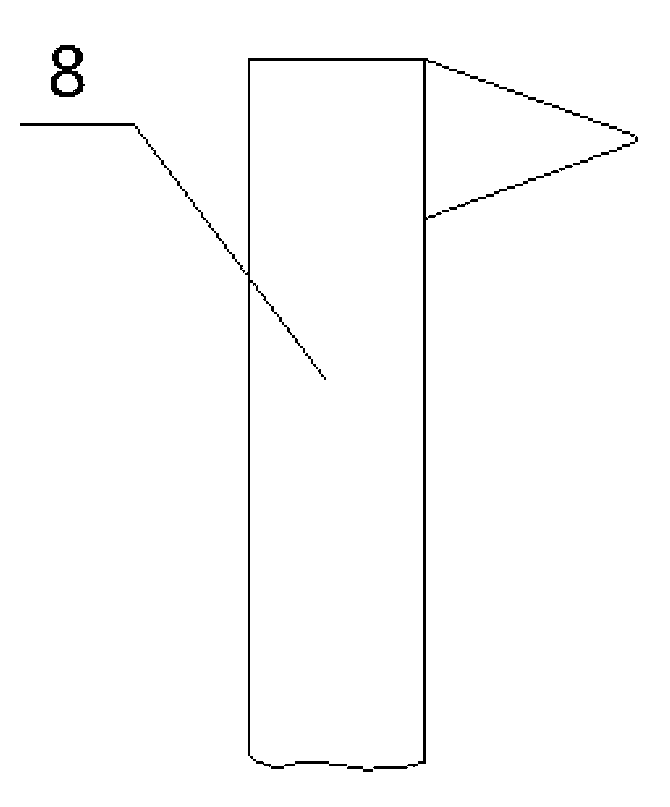

[0022] Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, the device used in the detection method for tooth surface wear of large involute spur gears is composed of three-jaw chuck 2, primary positioning ruler 3, secondary positioning ruler 4, measuring claw slideway 5, vernier ruler 6, The vernier ruler lock nut 7, the measuring claw 8, the measuring claw lock nut 9, the measuring ruler 10, the positioning slider 11, the positioning slider locking nut 12 and the positioning ruler locking nut 13 are formed, wherein the three-jaw chuck 2 consists of Small bevel gear 14, flat rectangular thread 15, claw 16 and chuck body 17 form, also have wrench to insert square hole and large bevel gear. The three-jaw chuck adopts the commonly used chuck for clamping workpieces on machine tools. It consists of a large bevel gear, three small bevel gears and three jaws. The three small bevel gears mesh with the large bevel gear. The back of the large bevel gear has a Planar re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com