Measuring device and method for large-dimension slewing platform slide rail flatness

A technology of a rotary platform and a measuring device, which is applied in the direction of measuring devices, fluid utilization devices, instruments, etc., and can solve problems that do not involve the use method of a large-scale rotary platform guide rail measuring device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but the scope of protection of the present invention is not limited to the following embodiments.

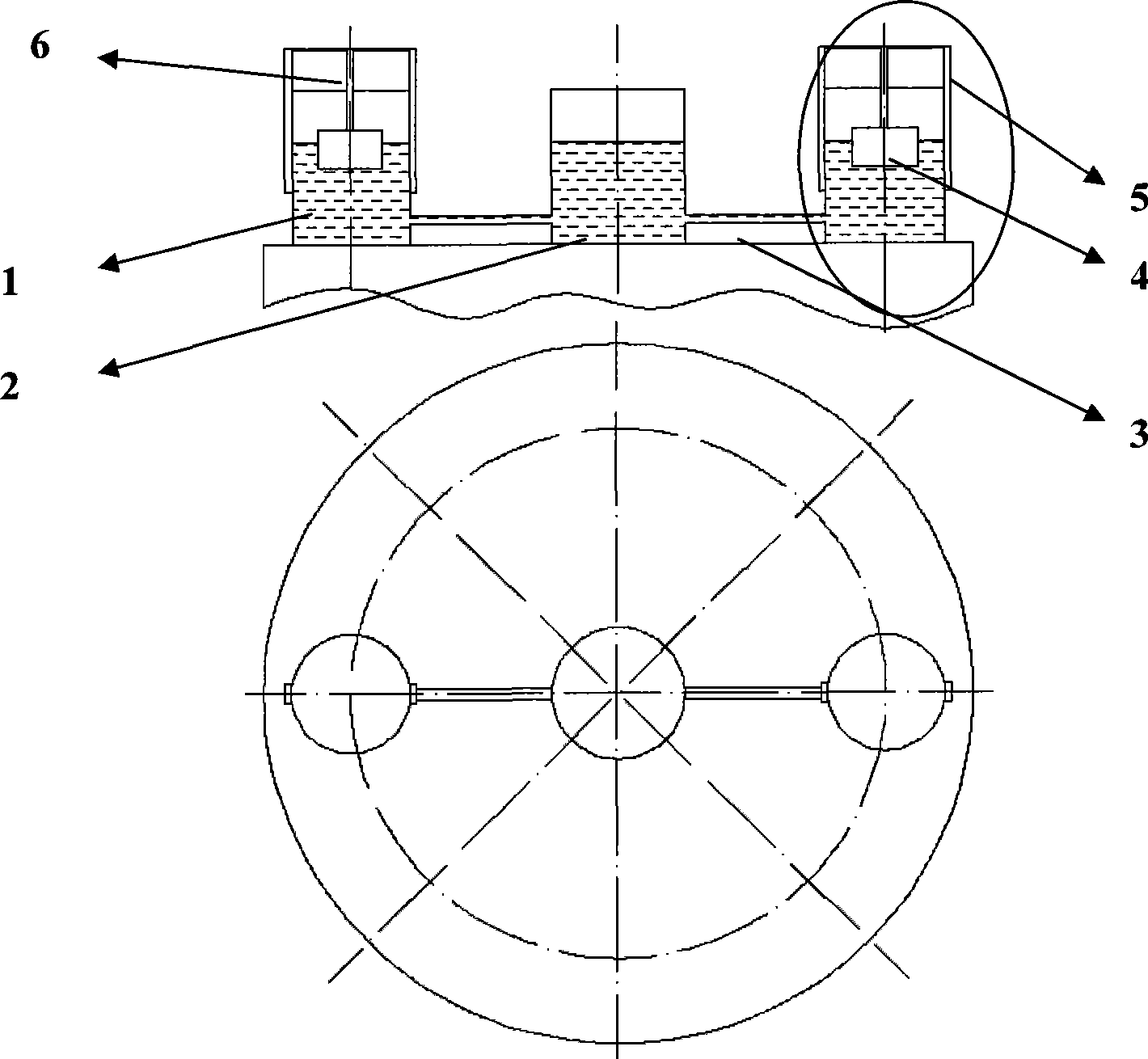

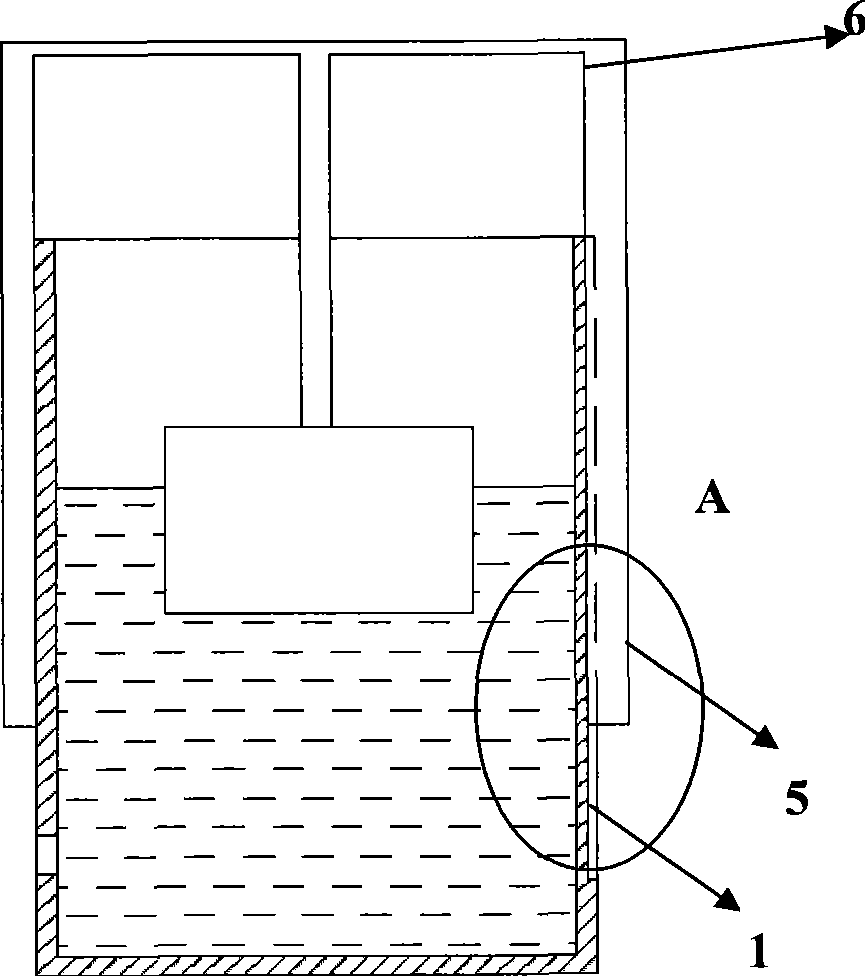

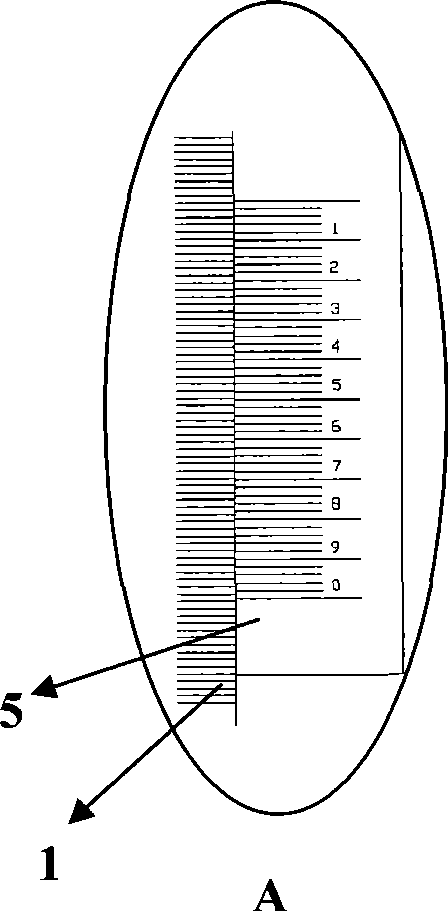

[0024] Such as figure 1 As shown, this embodiment includes: a mobile measuring cup 1 , a reference measuring cup 2 , a conduit 3 , a buoy 4 , a caliper 5 , and a connecting rod 6 . Both the mobile measuring cup 1 and the reference measuring cup 2 have transparent openings. The moving measuring cup 1 and the reference measuring cup 2 are connected through the conduit 3, the buoy 4 floats on the liquid surface of the moving measuring cup 1, the buoy 4 is connected with the caliper 5 through the connecting rod 6, and the scale on the caliper 5 is connected with the moving measuring cup 1. Vernier calipers are formed between the scales for measurement.

[0025] Such as Figure 2-3 As shown, the mobile measuring cup 1 is provided with grooves away from t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com