Efficient cleaning equipment for vernier calipers for detection equipment

A vernier caliper and detection equipment technology, which is applied to the cleaning method using tools, the cleaning method using liquid, cleaning methods and utensils, etc., which can solve the problems of insufficient cleaning and comprehensiveness, time-consuming and labor-intensive work, and low work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

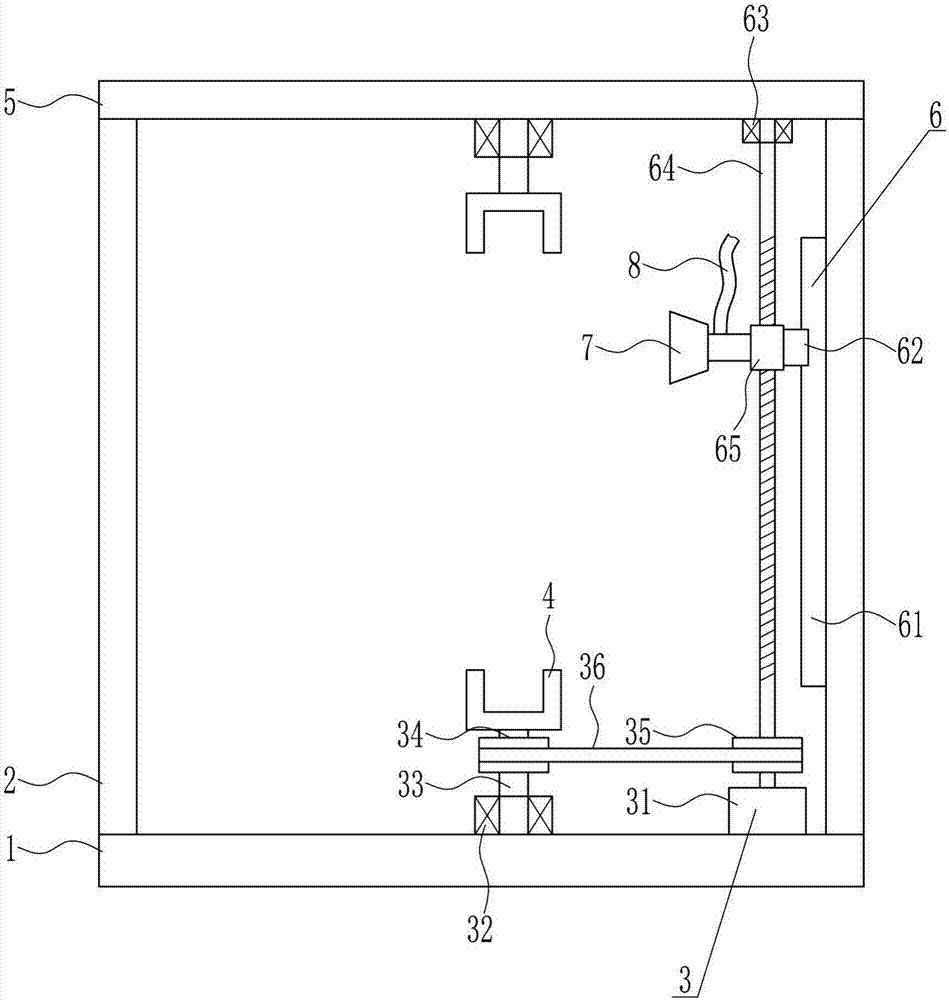

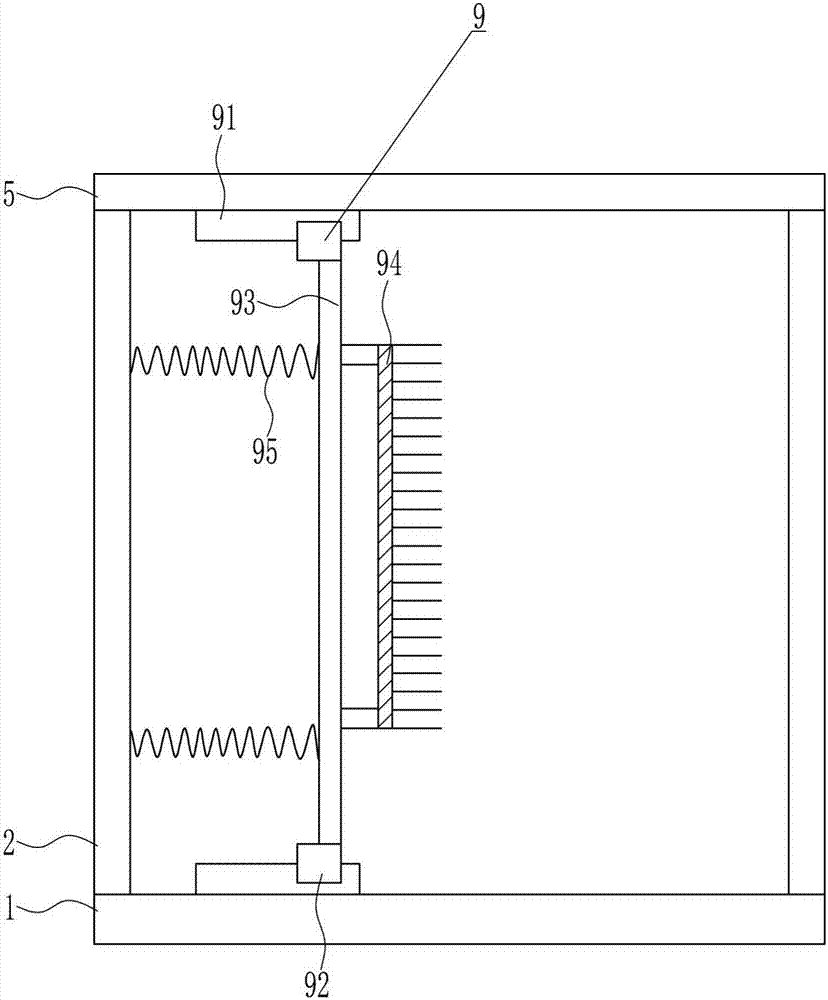

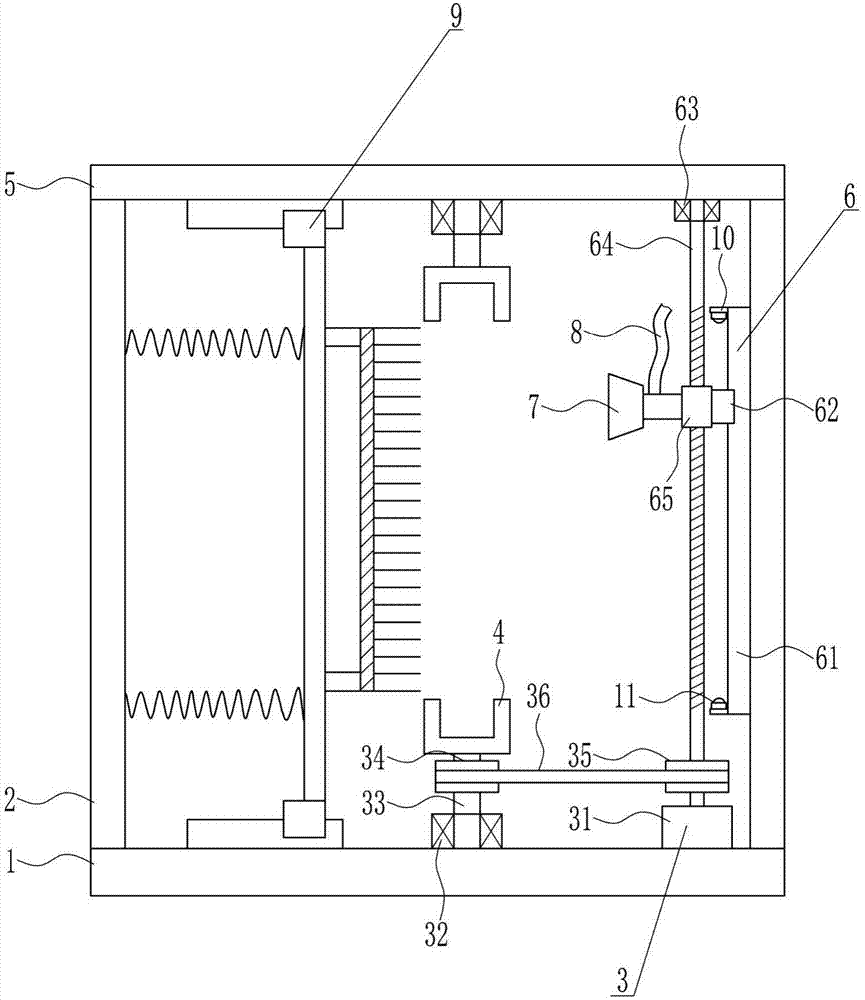

[0036] A vernier caliper efficient cleaning equipment for testing equipment, such as Figure 1-7 As shown, it includes a bottom plate 1, a bracket 2, a rotating device 3, a block 4, a top plate 5, an up and down moving device 6, a nozzle 7 and a water inlet pipe 8, and the top of the bottom plate 1 is vertically installed with a bracket 2 by means of bolt connection. , the top between the two brackets 2 is connected horizontally with a top plate 5 by bolts, the top of the bottom plate 1 and the bottom of the top plate 5 are provided with a rotating device 3, the rotating part of the rotating device 3 is connected with a block 4, and the right side of the bracket 2 The left side is provided with up and down moving device 6, and sprinkler head 7 is installed on the moving part of up and down moving device 6, is connected with water inlet pipe 8 on the shower head 7.

Embodiment 2

[0038] A vernier caliper efficient cleaning equipment for testing equipment, such as Figure 1-7 As shown, it includes a bottom plate 1, a bracket 2, a rotating device 3, a block 4, a top plate 5, an up and down moving device 6, a nozzle 7 and a water inlet pipe 8, and the top of the bottom plate 1 is vertically installed with a bracket 2 by means of bolt connection. , the top between the two brackets 2 is connected horizontally with a top plate 5 by bolts, the top of the bottom plate 1 and the bottom of the top plate 5 are provided with a rotating device 3, the rotating part of the rotating device 3 is connected with a block 4, and the right side of the bracket 2 The left side is provided with up and down moving device 6, and sprinkler head 7 is installed on the moving part of up and down moving device 6, is connected with water inlet pipe 8 on the shower head 7.

[0039] The rotating device 3 includes a first motor 31, a first bearing seat 32, a rotating shaft 33, a first pu...

Embodiment 3

[0041] A vernier caliper efficient cleaning equipment for testing equipment, such as Figure 1-7 As shown, it includes a bottom plate 1, a bracket 2, a rotating device 3, a block 4, a top plate 5, an up and down moving device 6, a nozzle 7 and a water inlet pipe 8, and the top of the bottom plate 1 is vertically installed with a bracket 2 by means of bolt connection. , the top between the two brackets 2 is connected horizontally with a top plate 5 by bolts, the top of the bottom plate 1 and the bottom of the top plate 5 are provided with a rotating device 3, the rotating part of the rotating device 3 is connected with a block 4, and the right side of the bracket 2 The left side is provided with up and down moving device 6, and sprinkler head 7 is installed on the moving part of up and down moving device 6, is connected with water inlet pipe 8 on the shower head 7.

[0042] The rotating device 3 includes a first motor 31, a first bearing seat 32, a rotating shaft 33, a first pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com