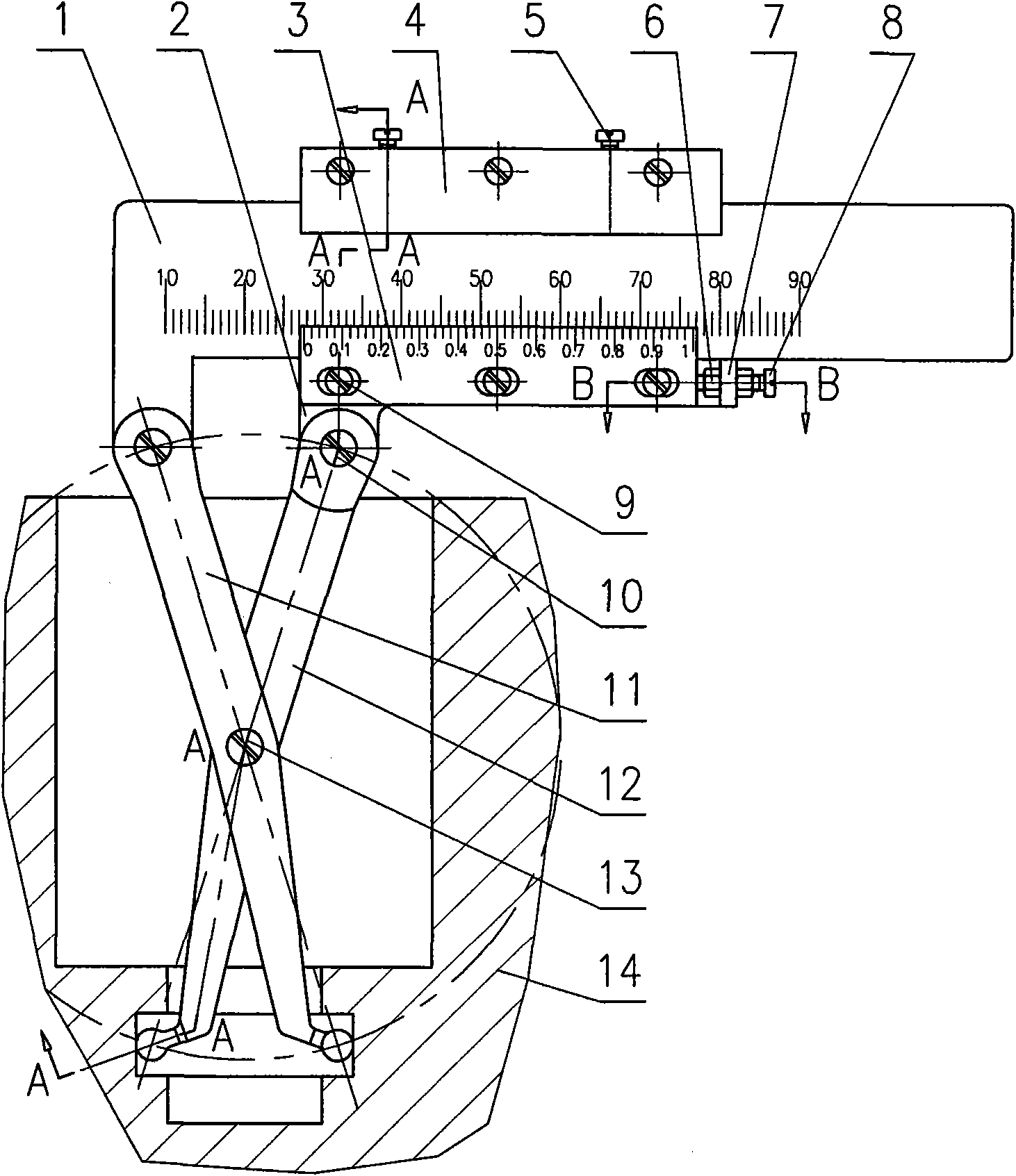

Level vernier caliper

A vernier caliper and lever technology, used in sliding gauges, mechanical diameter measurement, measuring gauges, etc., can solve the problems of difficult measurement and the measurement of inner diameter cannot be completed with ordinary vernier calipers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

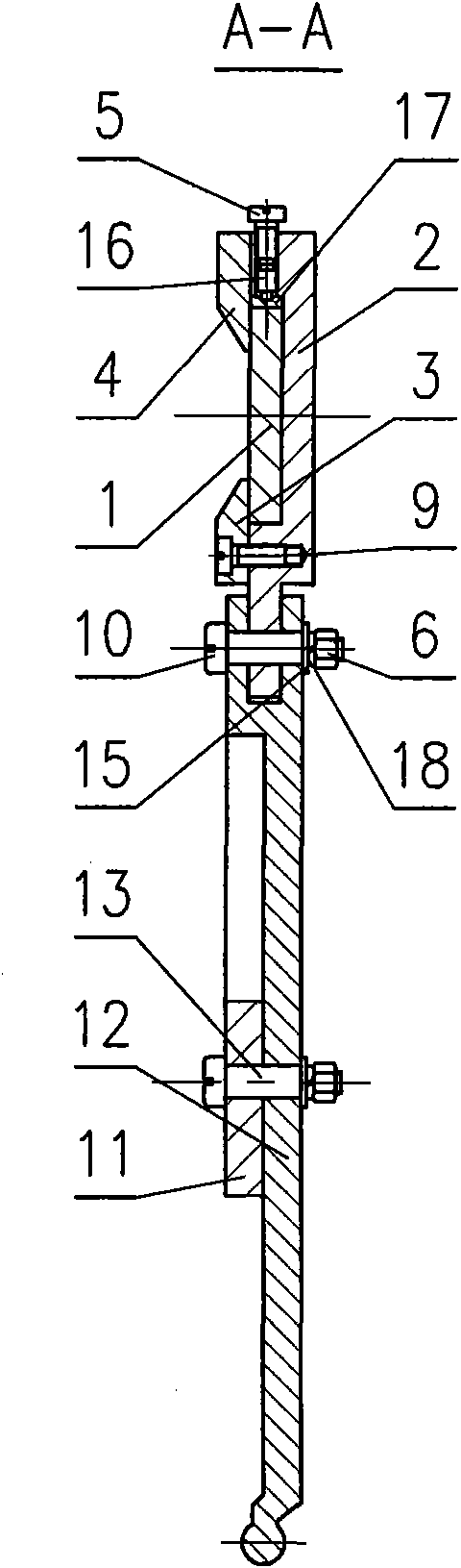

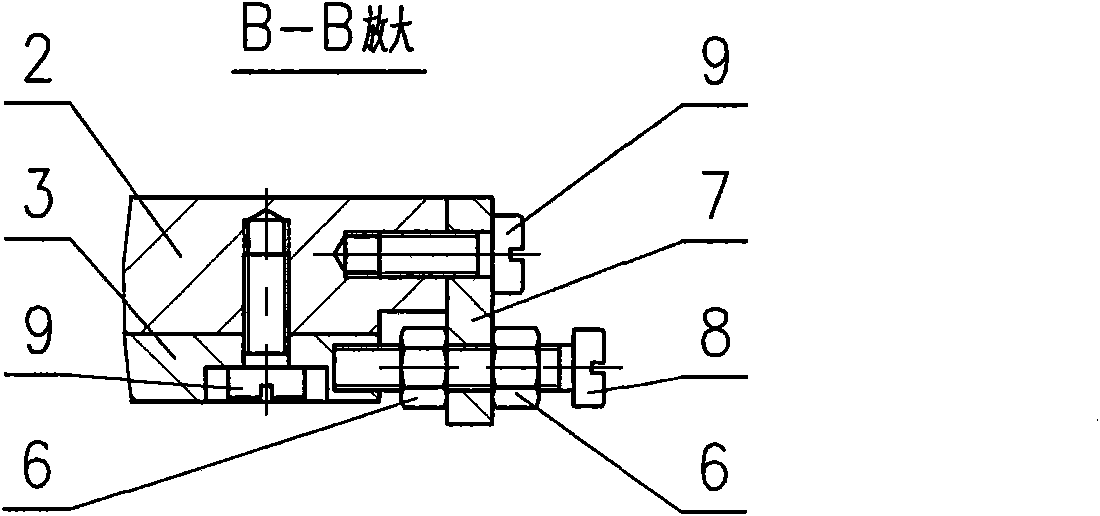

[0014] The accompanying drawing is an assembly drawing of a lever vernier caliper with a measuring range of 15-75 millimeters. In the accompanying drawings, the upper arm (11) and the lower arm (12) are connected together with a long shaft (13), a flat washer (15), a spring washer (18) and a nut (6) through their middle holes to reach the upper arm ( 11) and the lower arm (12) can rotate relatively and have the smallest gap with the major axis (13). It can be realized by the process of hole and shaft matching and mutual grinding. The gap between the upper arm (11) and the lower arm (12) is the smallest in the axial direction of the major axis (13). That is, the upper arm (11) and the lower arm (12) have the smallest gap between the large cylindrical end face of the major axis (13) and the flat washer (15). It is realized by controlling the length of the long axis (13) and the hole matching part and the total thickness of the upper arm (11) and the lower arm (12).

[0015] U...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com