Vernier scale for measuring bending radius and bending angle of numerically-controlled bending pipe

A technology of bending angle and bending radius, applied in the field of vernier ruler, can solve the problems of large size limitation of measuring elbow fittings, complex structure of measuring device, difficult to guarantee measurement accuracy, etc., and achieve low production cost, accurate reading and simple mechanical structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

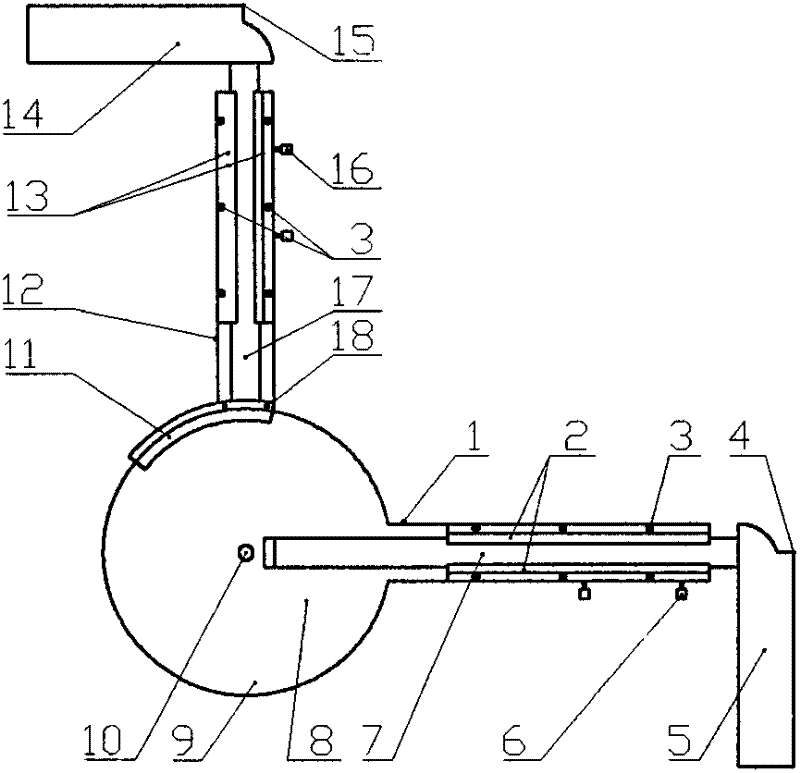

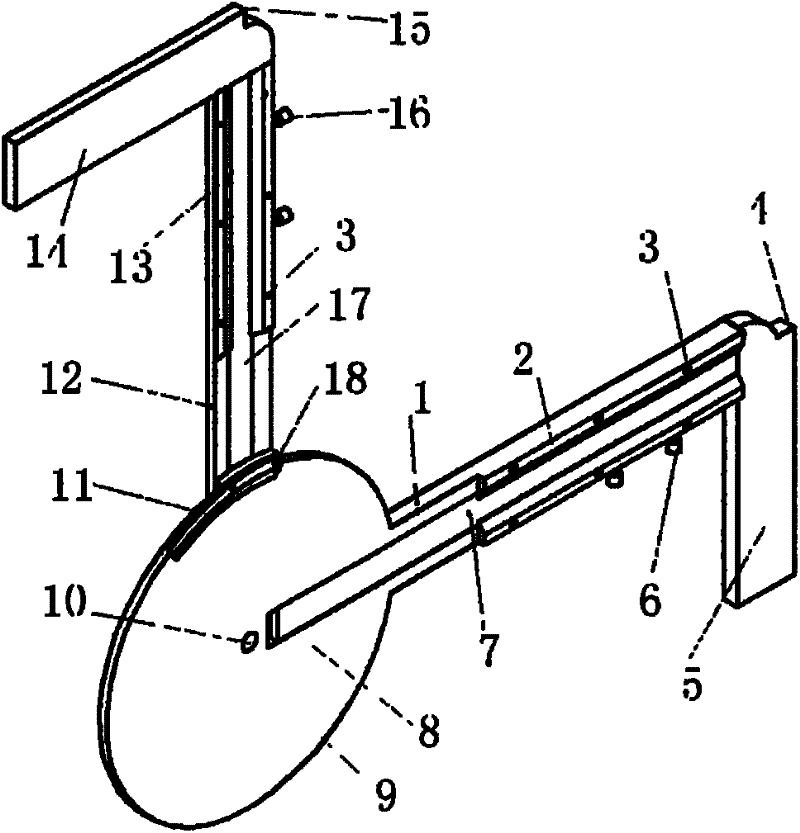

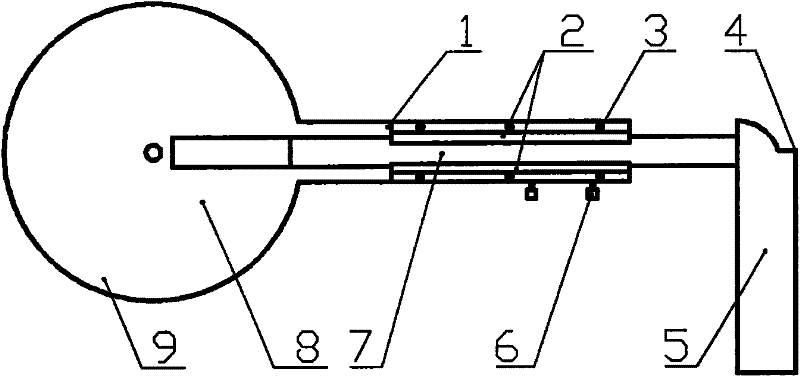

[0018] This embodiment is a vernier scale for measuring the bending radius and bending angle of a numerically controlled elbow, including a main scale 1 , an angle scale 8 and an auxiliary scale 12 . The angle ruler 8 is disc-shaped, and the main chi 1 and the auxiliary chi 12 are bar-shaped, and the angle ruler 8 plate body has a ruler frame of the main chi 1 extending radially, and the angle vernier ruler 11 is arc-shaped. The main ruler 1 is installed on the disc surface of the angle ruler 8 through the ruler frame, and the lower end of the auxiliary ruler 12 is connected to the disc-shaped center of the angle ruler 8 through the connecting pin 10, and the auxiliary ruler 12 can rotate freely; the main ruler 1 and the center line of the length direction of the auxiliary ruler 12 pass through the center of the angle ruler 8, and the angle formed by the center line of the main ruler 1 and the auxiliary ruler 12 is the angle of bending of the pipe, and the angle value is passed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com