Milling residual stress measuring method based on deflection changes and inverse method

A residual stress and milling technology, which is applied in the fields of gradual corrosion and peeling, stress measurement, and milling residual stress measurement. Simple, inexpensive equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In the following, the basic idea, device and working process of the present invention will be introduced in detail with reference to the accompanying drawings.

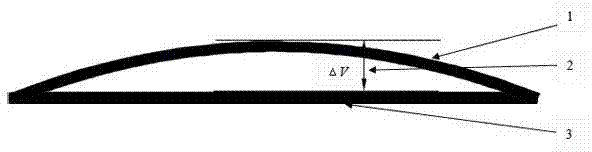

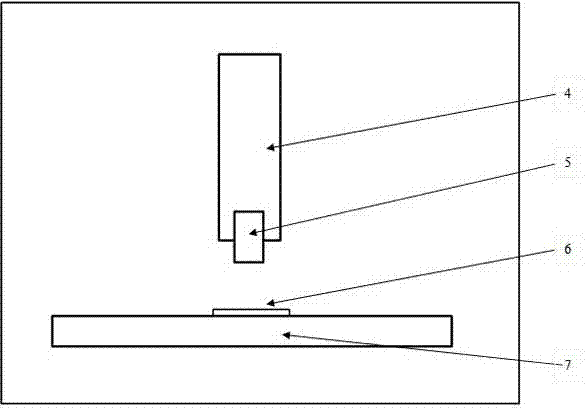

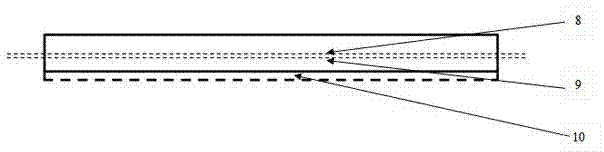

[0026] The main idea of this invention is to carry out such as image 3 As shown in the corrosion removal material, the stress layer is divided into multiple corrosion stripping layers, and the thickness of the material layer removed by each corrosion is measured with a vernier caliper, and figure 2 As shown, the laser displacement sensor is used to scan the parts on the machine tool to measure the changes in the deflection of the parts after each corrosion. image 3 The change in the position of the neutral layer of the part shown results in the stress layer produced as figure 1 The change in the bending moment shown, combined with the change in the measured deflection, reverses the residual stress value.

[0027] Set the length of the part as L and the height as h, and the position of the neutral layer of the pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com