Simulative testing device and method of drilling tool thread dynamic fatigue

A technology of dynamic fatigue and simulation testing, applied in measuring devices, vibration testing, testing of machine/structural components, etc., to achieve smooth transmission, real-time monitoring data recording, and easy use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

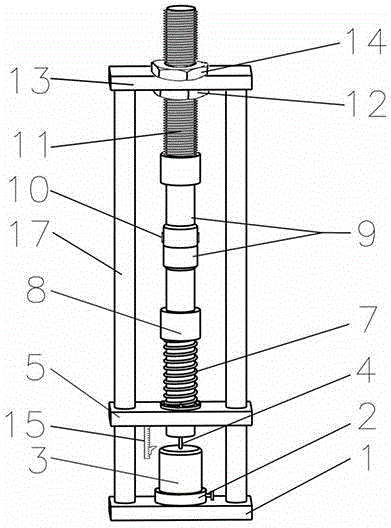

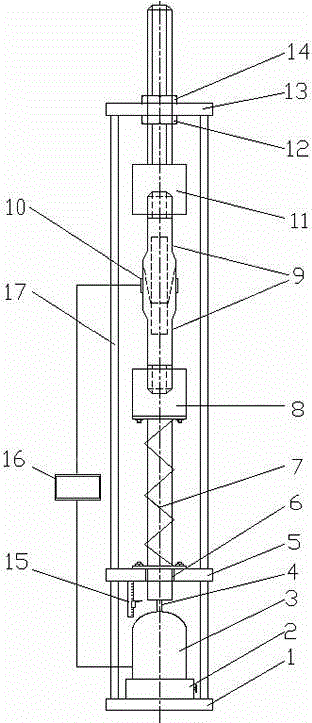

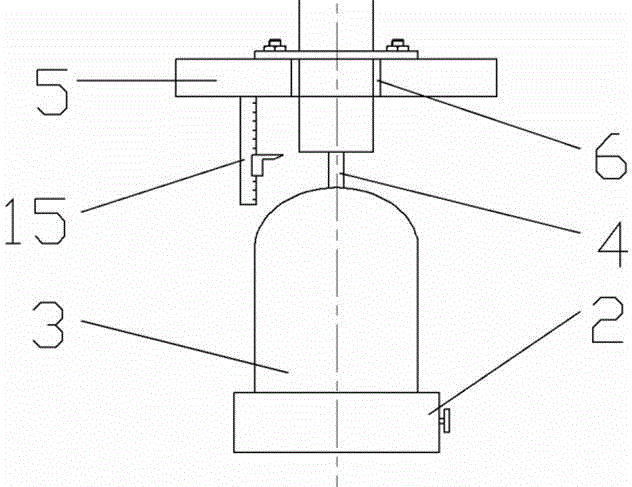

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0030] Such as figure 1 , figure 2 As shown, the present invention comprises a base 1, a fine-tuning lifting device 2 located at the center of the base 1, a vibrator 3 located on the fine-tuning lifting device 2, a base plate 5 located above the vibrator 3, and a base plate located above the base 5. Top plate 13, the sliding bearing 6 that is located at the center of the bottom plate 5, the lower connecting column 8 are installed in the sliding bearing 6, the vernier caliper 15 that is located at the lower end surface of the bottom plate 5, the upper connecting column 11 that is located at the center of the top plate 13, and the upper connecting column 11 that is located at the bottom plate 5 and The spring 7 between the lower connecting columns 8, the tension nut 14 arranged on the upper part of the upper connecting column 11, the compression nut 12 arranged on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com