Verticality detecting equipment and detecting method for product

A detection equipment and verticality technology, which is applied in the verticality detection equipment and detection field of products, can solve the problems of numerous detection steps, low efficiency, inconsistent processing quality, etc., and achieve the effect of high testing efficiency, high detection efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

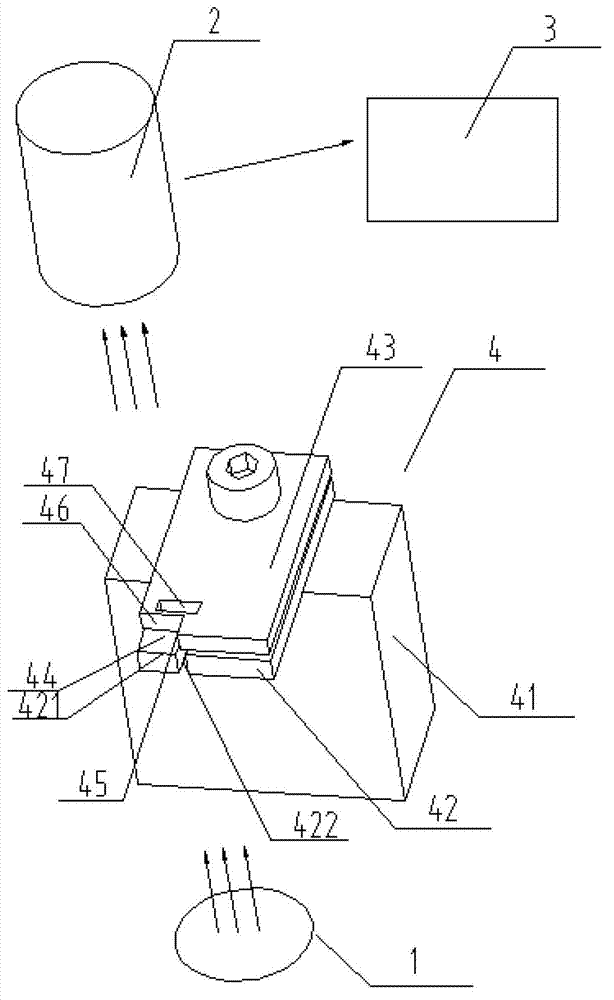

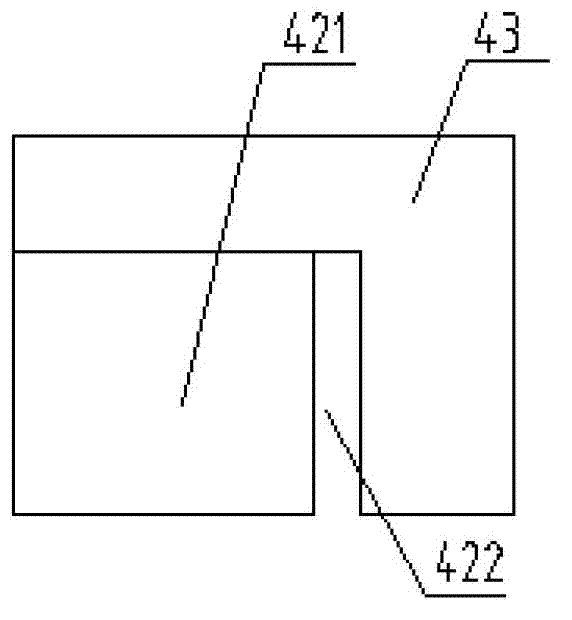

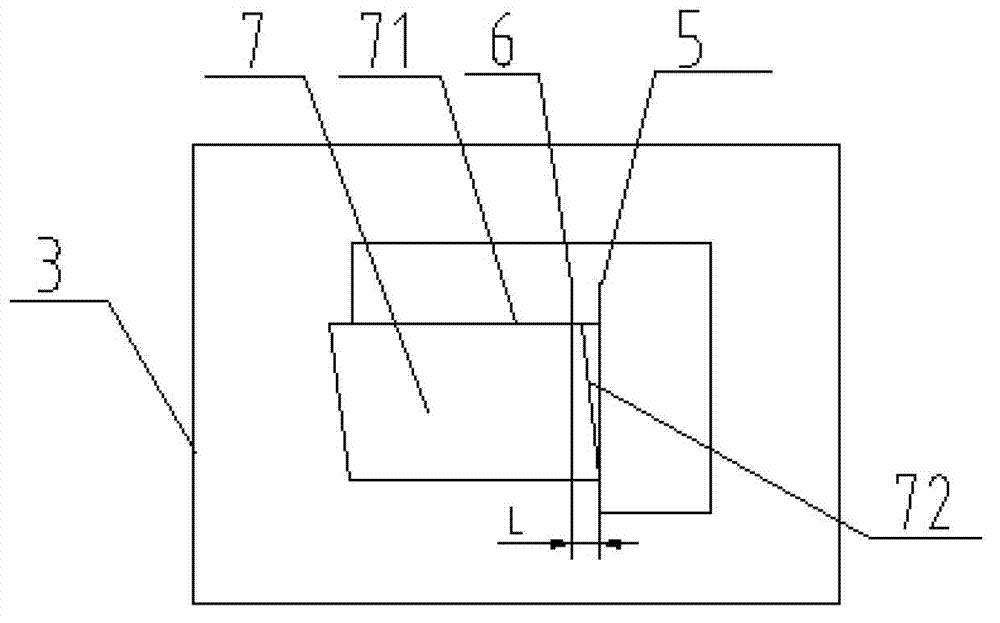

[0025] Embodiment one: if figure 1 and figure 2 As shown, a product verticality detection equipment includes a light source 1, an image detector 2 and a display screen 3, the display screen 3 is connected to the image detector 2, the light source 1 is located below the image detector 2, and the light source 1 and the image detector A light transmission mechanism 4 is arranged between the instruments 2. The light transmission mechanism 4 includes a base 41, a support plate 42 and a standard plate 43. The support plate 42 is fixedly mounted on the base 41, and the standard plate 43 is fixedly mounted on the support plate 42. The standard plate 43 is provided with a test hole 44, the test hole 44 is located on a corner of the standard plate 43, the test hole 44 only has two adjacent vertical surfaces perpendicular to the upper surface of the support plate 42, the two vertical surfaces are respectively the first vertical surface 45 and the second vertical surface 46, the support...

Embodiment 2

[0027] Embodiment 2: This embodiment is basically the same as Embodiment 1, and its difference is only that an inner side of the rectangular light-transmitting hole 422 is on the same plane as the second vertical surface 46, and the width of the rectangular light-transmitting hole (that is, the width of the rectangular light-transmitting hole The linear distance from one inner surface of 422 to the other inner surface facing the inner surface) is 1 mm, and the magnet 47 extends horizontally along the first vertical surface 45 and passes through the plane where the second vertical surface 46 is located.

Embodiment 3

[0028] Embodiment three: this embodiment is basically the same as embodiment one, and its difference is only that the test hole 44 is located on a side of the standard plate 43, the test hole 44 has three sides and wherein two adjacent sides are perpendicular to the support The two vertical surfaces on the upper surface of the board are the first vertical surface 45 and the second vertical surface 46 respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com