Heat resistance heat flow meter calibration method and implementation device thereof

A calibration method, heat flow meter technology, applied in the direction of material heat development, etc., can solve the problems of no application case, no grading, low accuracy of heat flow sensor, etc., and achieve the effect of reasonable design and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

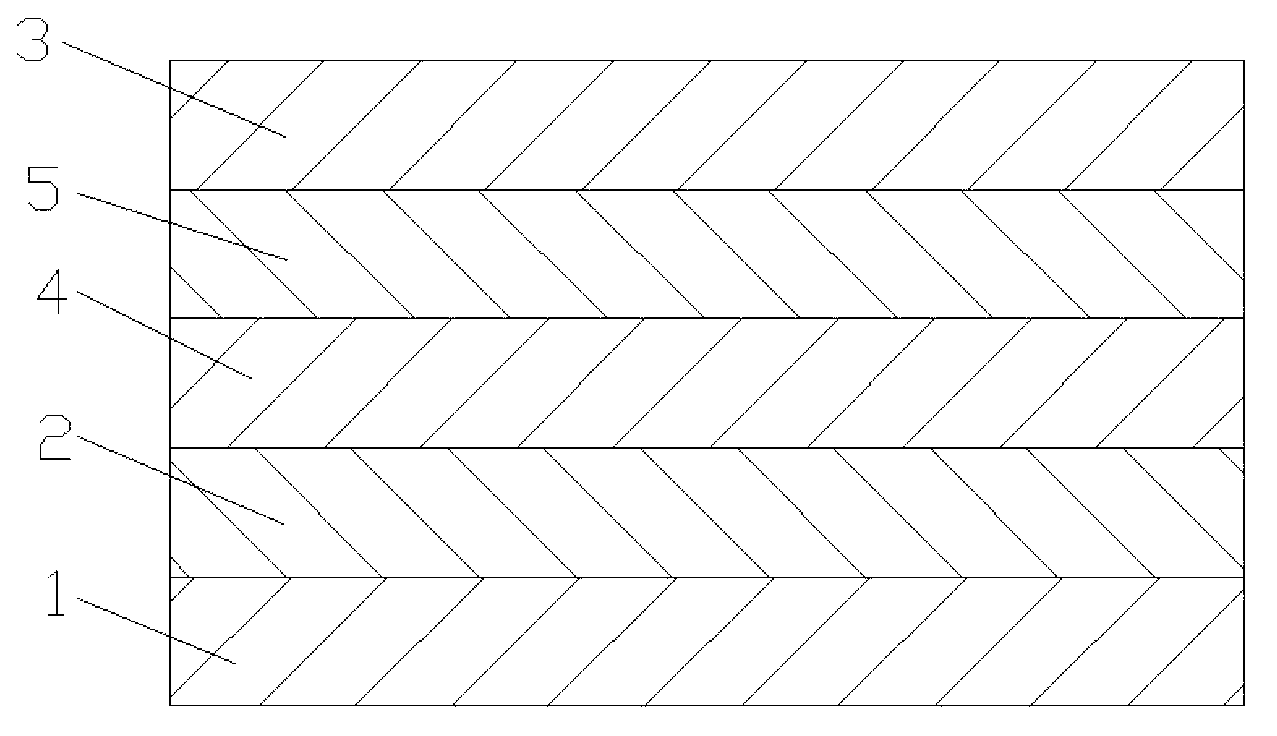

[0014] Such as figure 1 As shown, the present invention includes a thermal insulation plate 1, a hot plate 2, a cold plate 3, a thermal conductivity standard plate 4 and a thermal resistance heat flow meter 5. A hot plate 2, a thermal conductivity standard plate 4 and a thermal resistance heat flow meter 5 are arranged in sequence between the plates 3, temperature sensors are respectively arranged on both sides of the thermal conductivity standard plate 4, and the heating element of the hot plate 2 is a polyimide electrothermal film.

[0015] In the working process of the present invention, according to the formula The heat flux through the thermal conductivity standard plate can be calculated, where q is the heat flux through the thermal conductivity standard plate, λ is the thermal conductivity of the thermal conductivity standard plate, △t is the temperature difference on both sides of the thermal conductivity standard plate, δ—thermal conductivity Coefficient of the thic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com