Pencil, pencil processing method and pencil groove milling machine for machining pencil

A pencil and groove grinding technology, which is applied to non-active pencils, metal processing equipment, grinding machines, etc., can solve the problems of increasing pencil processing procedures, easy sliding of pencils up and down, and no anti-skid structure, so as to reduce labor costs, good anti-skid, and work high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further explained below in conjunction with the drawings:

[0037] Referring to the drawings: the non-slip pencil in this embodiment includes a penholder 1, and a set of spaced annular grooves 2 are provided on the outer surface of the penholder 1, and the annular grooves 2 are in a concave arc surface structure.

[0038] The method of processing the pencil of claim 1 includes the following steps:

[0039] (1) Choose a suitable plate, which is 120% of the standard plate thickness;

[0040] (2) Plan a groove on the board, and put the pencil lead into the processed groove;

[0041] (3) Cutting the plate and processing it into pencil blanks;

[0042] (4) Place a set of annular grooves on the pencil grinder to simultaneously grind the outer surface of the pencil blank;

[0043] (5) Paint the surface of the pencil.

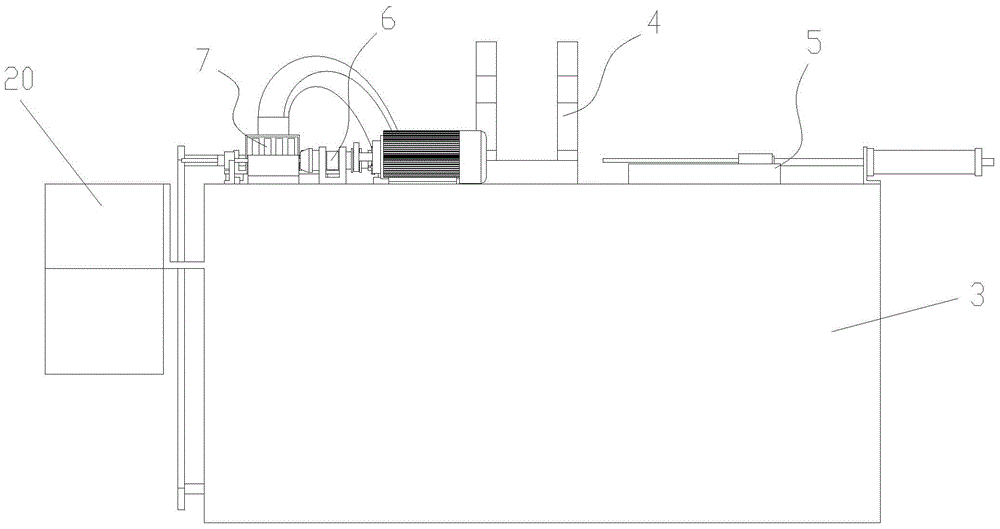

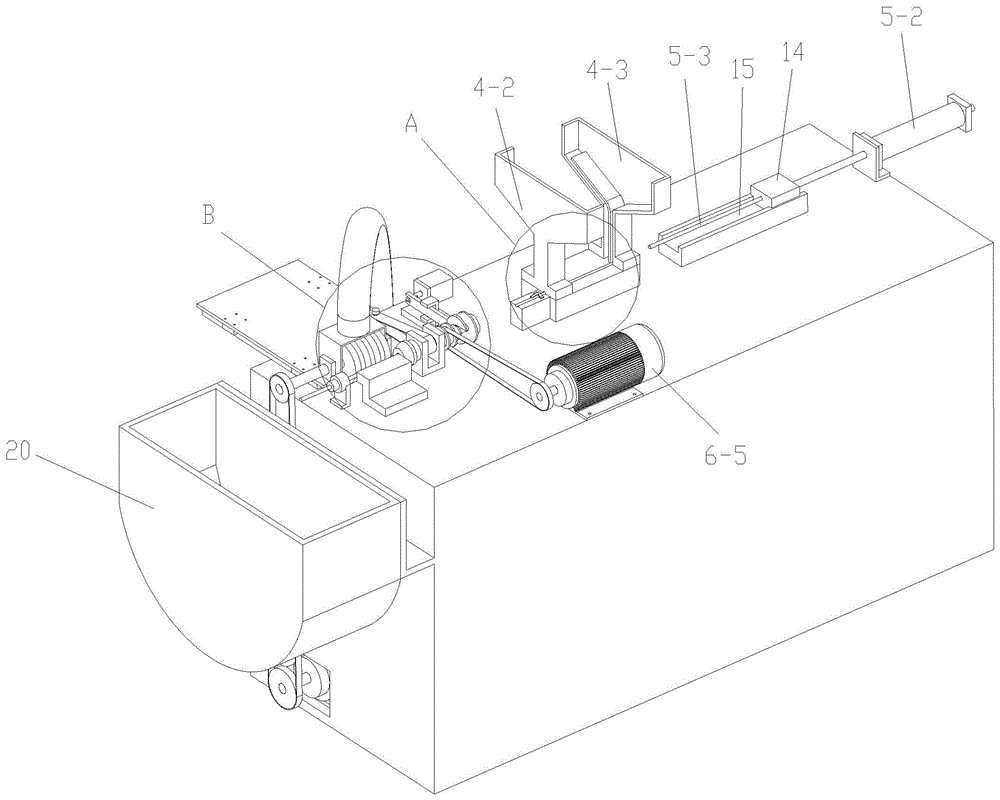

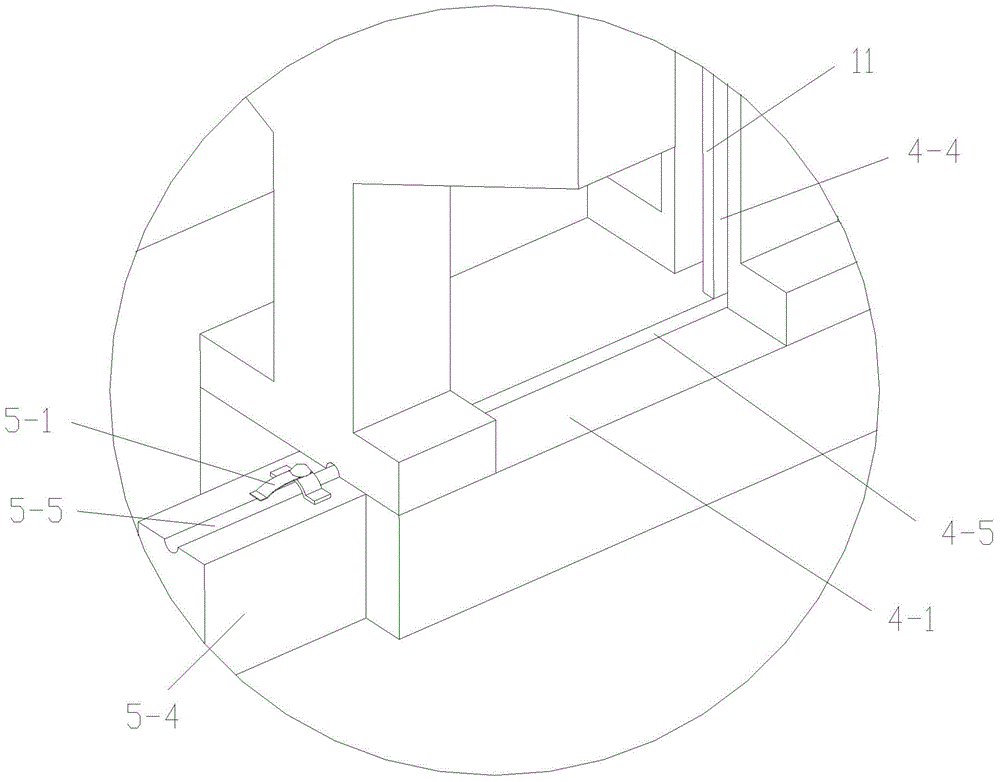

[0044] The pencil grinder applied to the pencil processing method includes a frame 3 on which is provided a blanking mechanism 4 for storing pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com