Novel hole drilling machine for processing plate materials and hole drilling method

A drilling machine and drilling mechanism technology, applied in wood processing equipment, drilling machines, manufacturing tools, etc., can solve the problems of high labor intensity of production personnel, large damage to the surface of the board, and affecting the quality of the board, so as to improve drilling efficiency, The effect of reducing labor intensity and reducing the number of computer operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

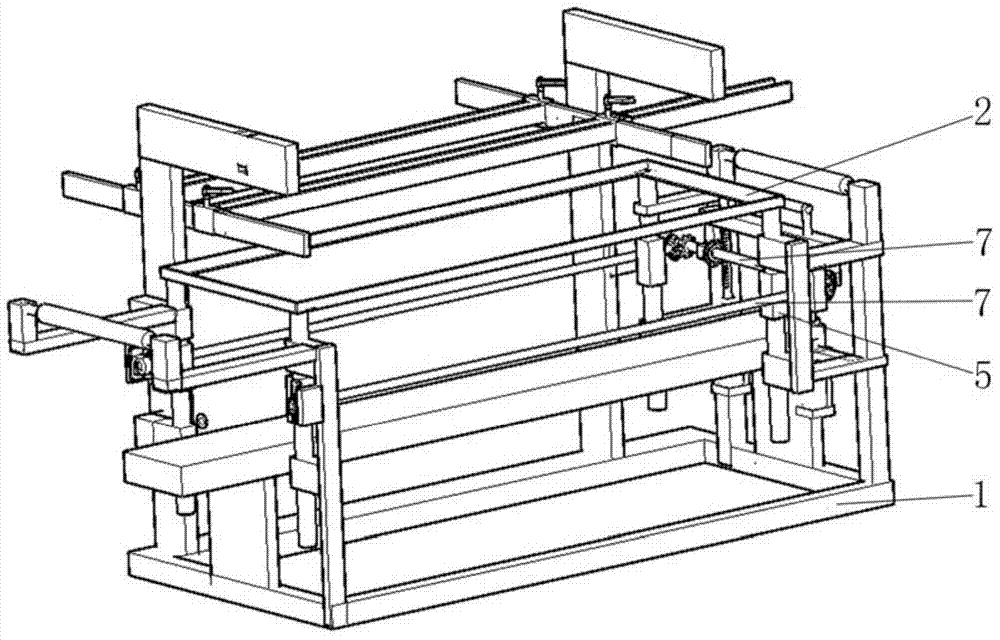

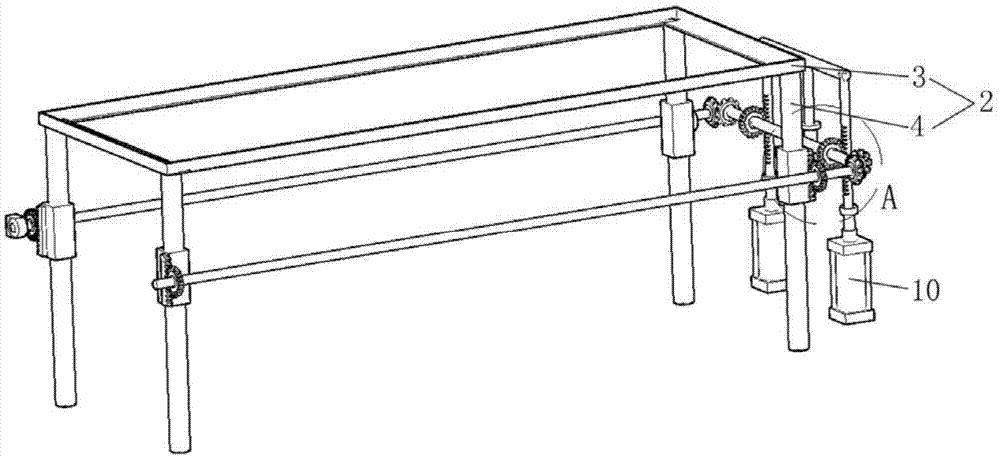

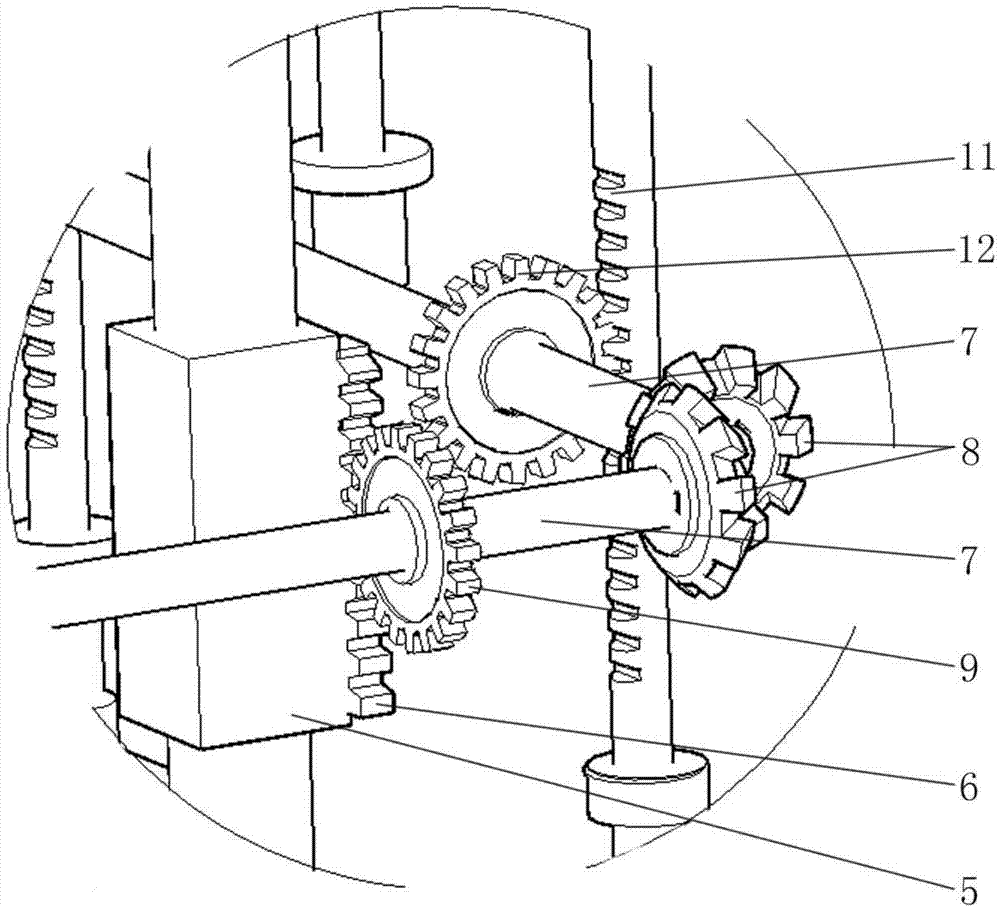

Embodiment 1

[0061] Such as figure 1 , 2 , The drilling machine shown in 3 has a bearing platform 2 installed on the frame 1 . In the first embodiment, the carrying platform 2 is composed of a carrying frame 3 with a rectangular outer contour and four lifting columns 4 , and the lifting columns 4 are respectively arranged at four corners of the carrying frame 3 . Lifting blocks 5 are installed on each lifting column 4, and lifting racks 6 are formed on the lifting blocks 5. Each lifting column 4 is connected by a lifting transmission shaft 7 . Driven gears 8 are installed on the ends of each lifting transmission shaft 7 , and the driven gears 8 on each lifting transmission shaft 7 mesh with each other. In addition, a lifting gear 9 that meshes with the lifting rack 6 is also provided on the lifting transmission shaft 7 . Simultaneously, a lifting cylinder 10 is installed on the frame 1 , and a driving rack 11 is installed on the piston rod of the lifting cylinder 10 . On the lifting t...

Embodiment 2

[0068] The difference between this embodiment 2 and embodiment 1 is that, as Figure 14 , 15 As shown, the transmission mechanism on the forward drilling mechanism 24 is composed of a transmission gear 36, a driven driven gear 37, a synchronous belt 54 and a row of drill bit gears 38. The transmission gear 36 is installed on the output shaft of the driving motor 35 , and the driven transmission gear 37 is installed in the mounting seat 26 . The transmission gear 36 and the driven transmission gear 37 are connected by a synchronous belt 54 . The row drill bit gear 38 is installed on the row drill bit 32 and links to each other with the synchronous belt 54 .

Embodiment 3

[0070] Utilize the drilling machine in embodiment 1 to drill the method on plate, its concrete steps are:

[0071] a) placing the carrier substrate 57 on the carrier frame 3, so that the upper surface of the carrier substrate 57 is flush with the carrier frame 3; at this moment, the carrier platform 2 is in the starting position;

[0072] b) along Figure 16 The plate feeding direction shown, the plate is placed on the carrier substrate 57;

[0073] c) Move the sheet material so that one side of the sheet material along the longitudinal direction of the carrying platform 2 is attached to the drilling datum plate 52; then, move the slide block 46 on the lateral positioning guide rail 44 according to the specification of the sheet material, and adjust the slide block on the lateral positioning guide rail 44 position on block 46;

[0074] d) Control the piston rods of each positioning cylinder 47 on the lateral positioning guide rail 44 to go down; push the sheet material, let ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com