Large caliber standard plate precison regulation stand

A standard plate, precision adjustment technology, applied in the field of precision adjustment racks, can solve the problems of installation and adjustment of large-caliber standard plates, and achieve the effects of novel structure, simple overall structure and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

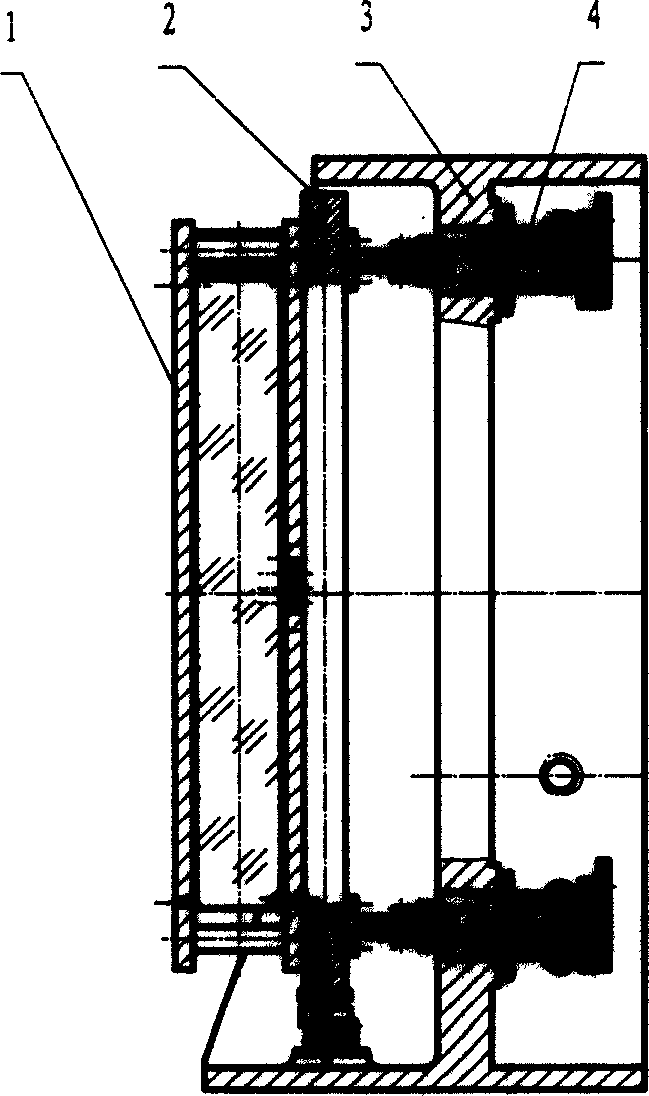

[0022] see first figure 1 , figure 1 It is a longitudinal sectional schematic diagram of the best embodiment of the large-diameter standard flat plate precision adjustment mount of the present invention. It can be seen that the large-diameter standard flat plate precision adjustment frame of the present invention mainly includes four major components: a frame component 1 , a frame adjustment plate component 2 , a seat frame 3 and a driving device component 4 .

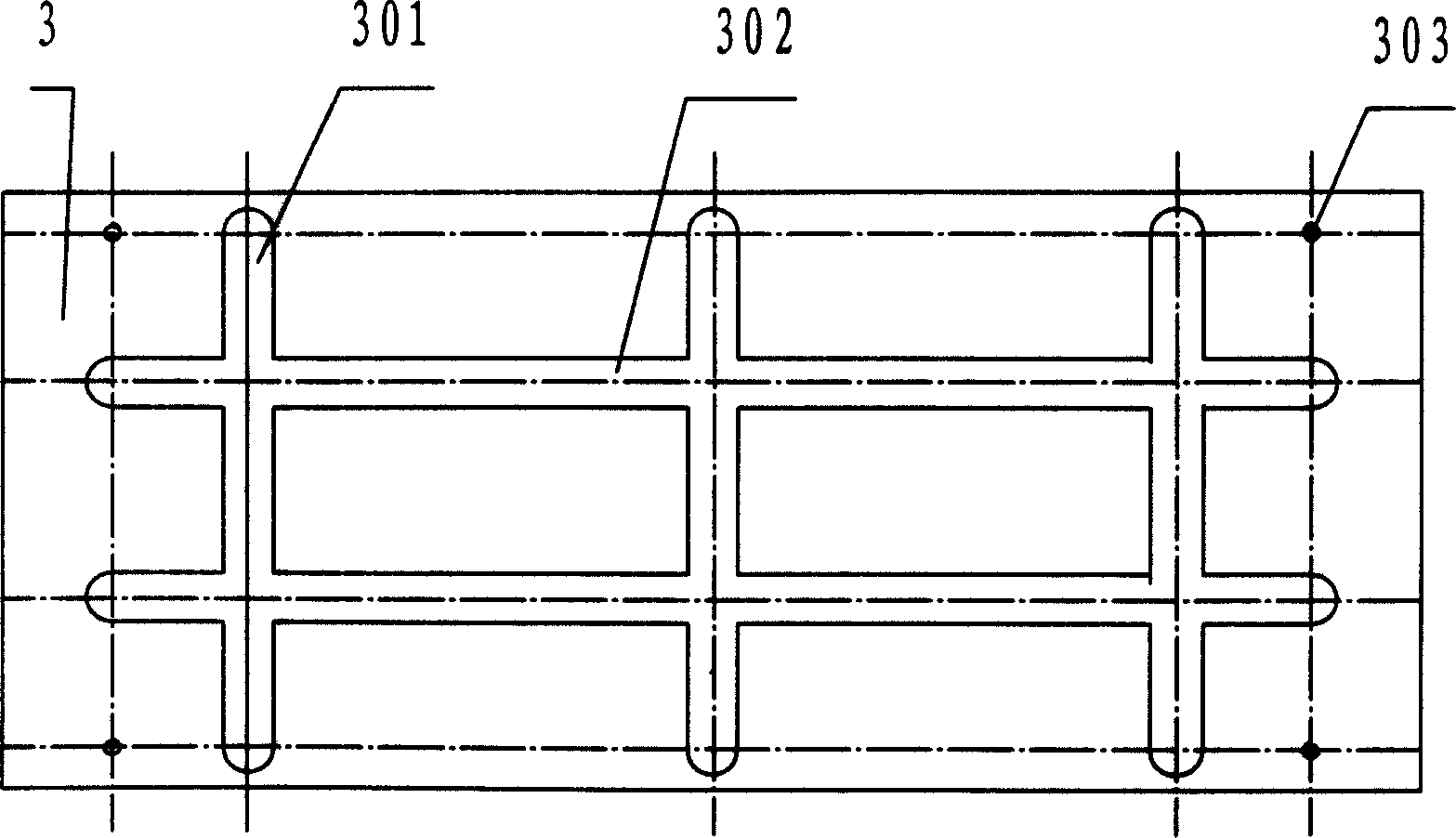

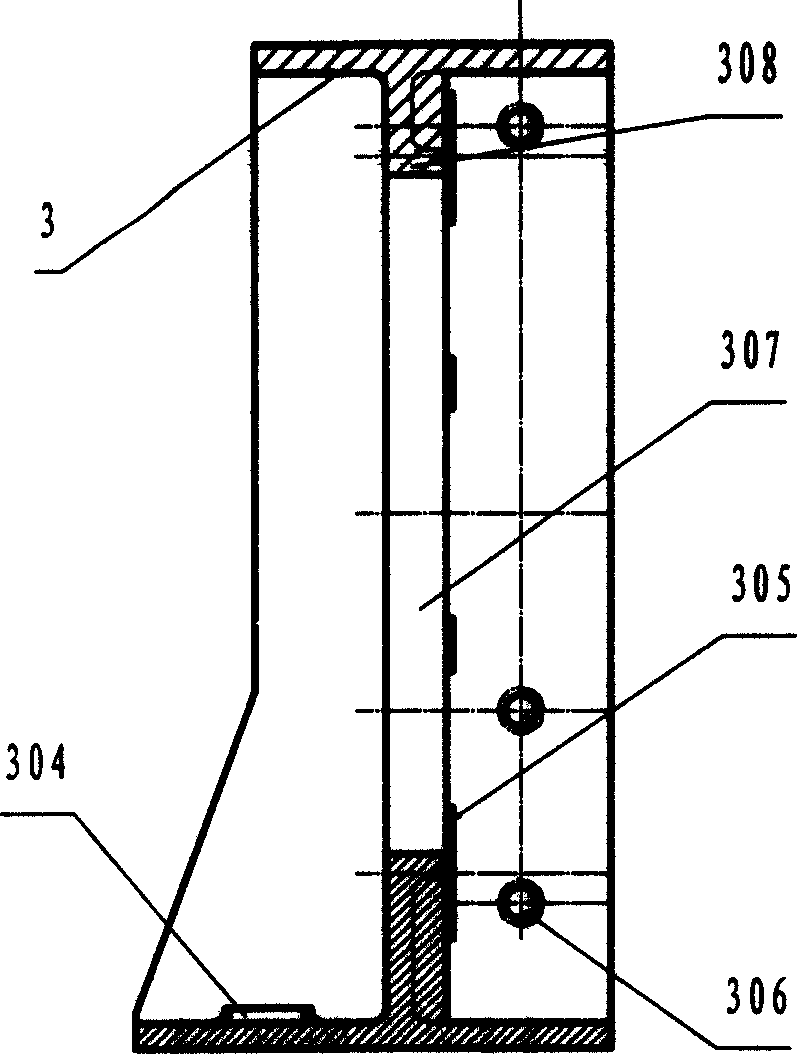

[0023] The structure of mount 3 is as figure 2 , image 3 shown. The seat frame 3 is integrally cast, wherein a round hole 307 with a diameter similar to the standard plate 106 is opened on the partition plate 308, and a casting pit is designed on the middle partition plate 308, which is used to improve the rigidity of the seat frame 3 and reduce the pressure of the seat frame. Rack 3 weight. There are two casting bosses 305 on the middle partition 308 , which are distributed diagonally, serving as a connection p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com