Electric box turnover device

A box-turning device and electric technology, which is applied in the direction of mold handling equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of high labor intensity, unsafety, and low work efficiency, so as to reduce labor intensity and be safe and convenient to use , the effect of high flipping efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] specific implementation plan

[0015] An embodiment of an electric box-turning device with a lifting tonnage of 4 tons will now be further described in detail in comparison with the accompanying drawings.

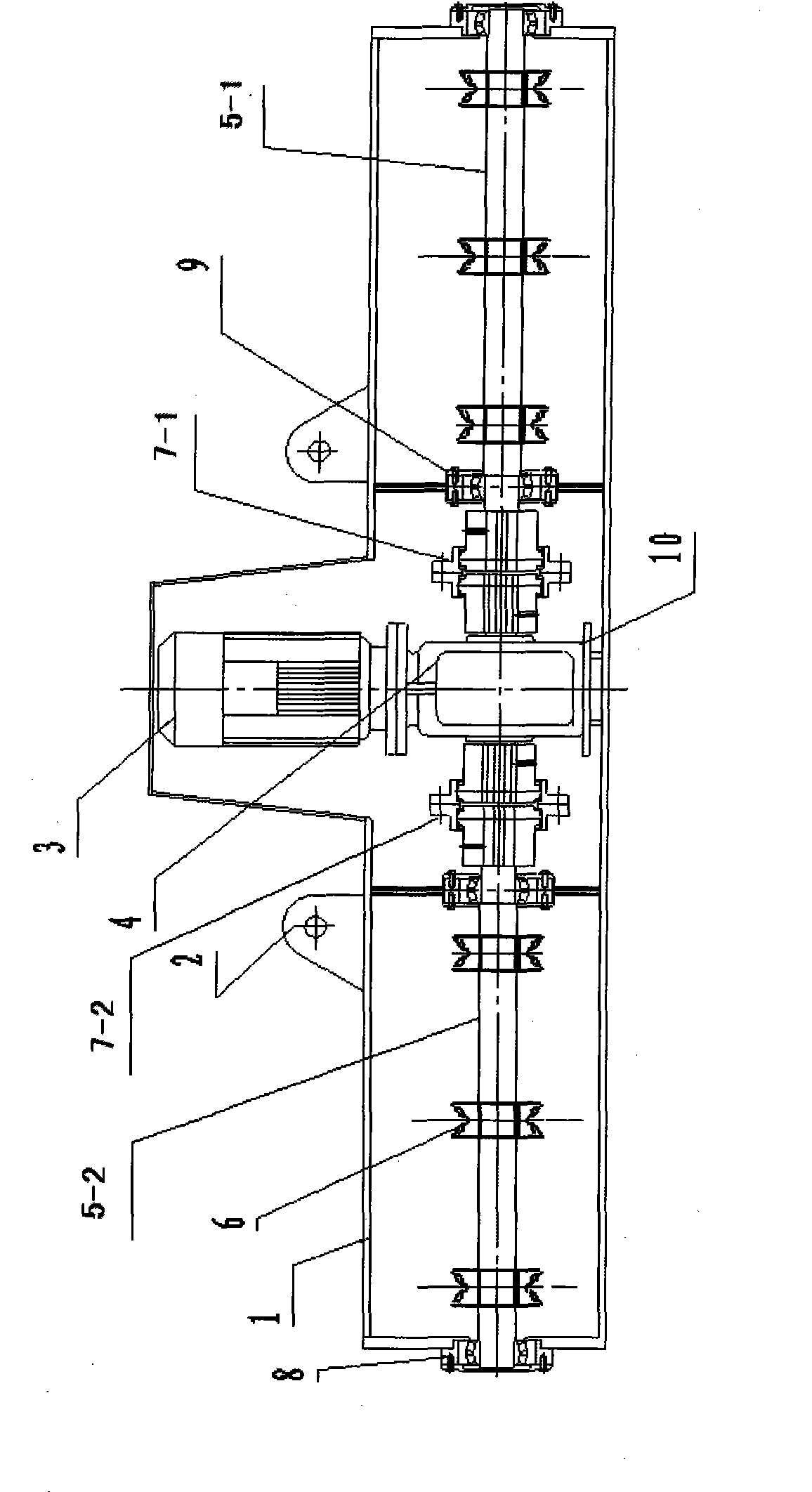

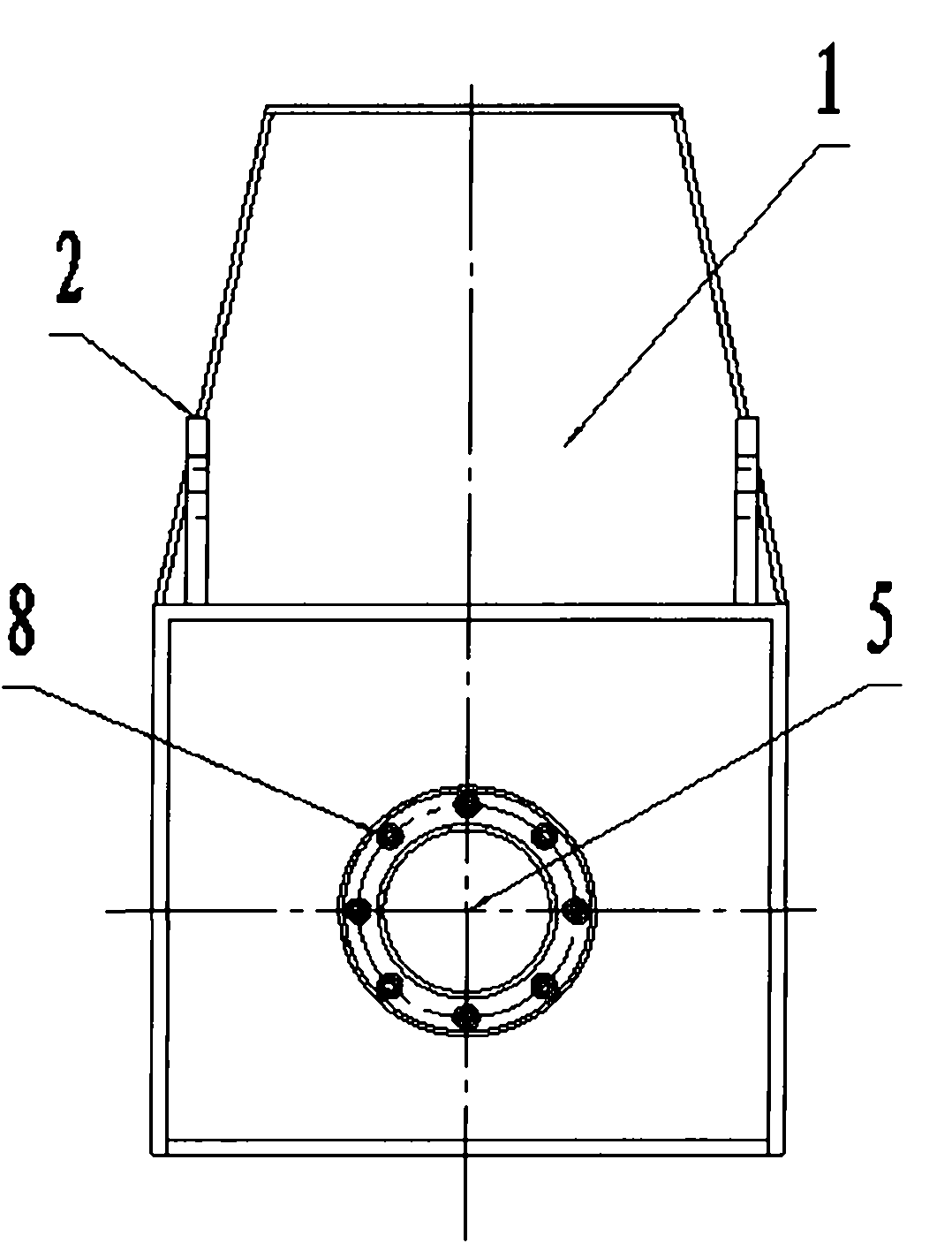

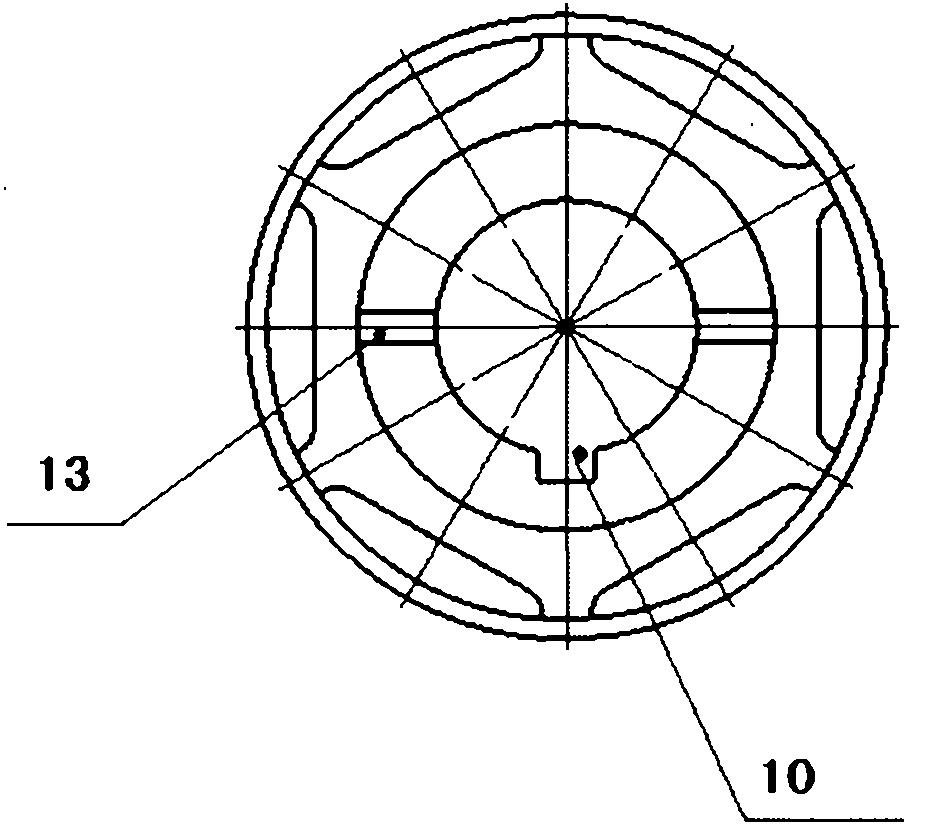

[0016] figure 1 It is a structural schematic diagram of the electric box turning device of the present invention, figure 2 It is the left view of the electric box turning device of the present invention. Such as figure 1 , 2 As shown, an electric box turning device includes a casing 1, a turning motor 3, a reducer 4, a transmission shaft, and a chain sprocket 6, wherein the casing 1 is welded by steel plates, and the front is in a convex shape. Four lifting lugs 2 are welded symmetrically on the four corners of the top of the body 1 that are mainly stressed, which is convenient for the lifting equipment to lift the whole device. The lower part of the shell 1 is open, and the groove on the top of the shell 1 is equipped with a Turnover motor 3, speed reducer 4 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com