Catalyst for selective hydrogenation of quinoline compounds and preparation method of catalyst

A compound and catalyst technology, applied in the field of chemical catalysts, can solve the problems of harsh reaction conditions, low intrinsic activity, poor stability, etc., and achieve the effects of simple preparation method, high TOF, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

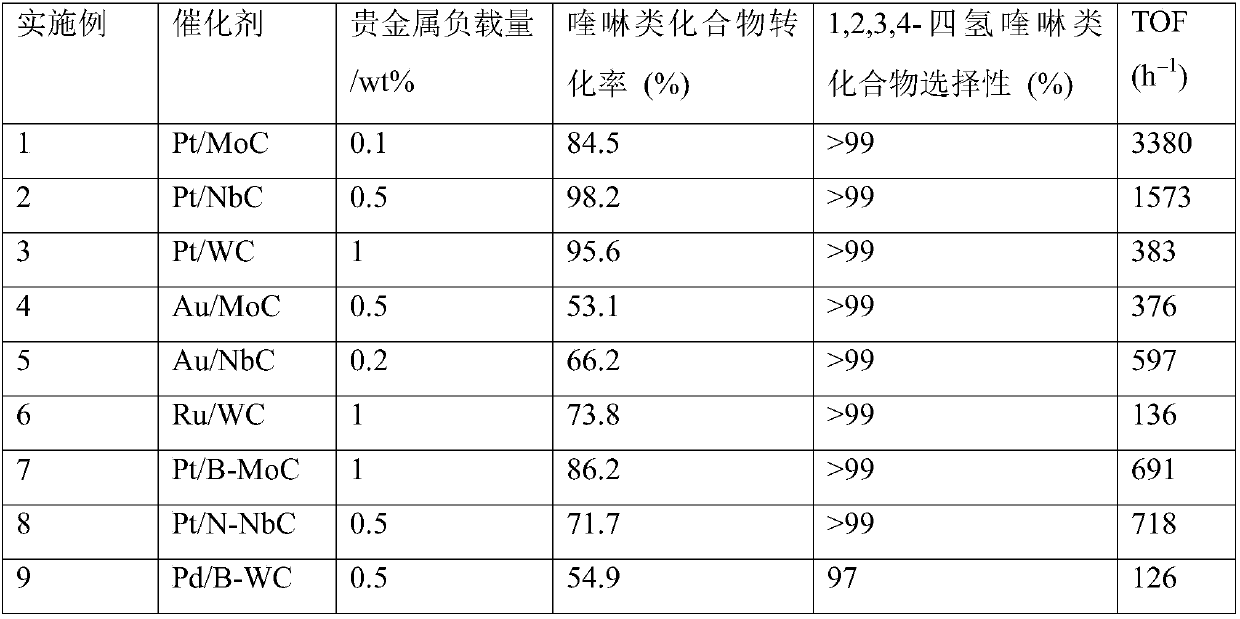

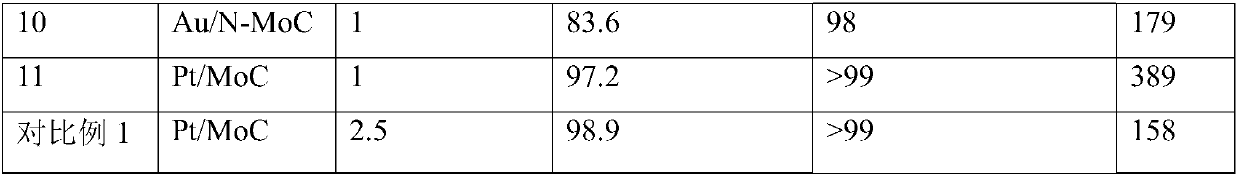

Examples

preparation example Construction

[0029] Preparation of vectors. In the present invention, the carrier can be carbide MC (M=Mo, Nb, W) or MC doped with nitrogen or boron, prepared by arc discharge method. Specifically, the metal M powder or M powder and a certain amount of boron powder are ground and mixed evenly, and then filled inside the graphite tube to form the anode. The outer diameter of the graphite tube may be 5-10 mm, the inner diameter may be 3-6 mm, and the length may be 8-20 cm. Wherein the B powder content may be 0.5-5 wt%. The cathode graphite rod was then fixed horizontally against the resulting anode material on a water-cooled copper base. The diameter of the graphite rod may be 5-10 mm, and the length may be 8-20 cm. Then vacuumize the reaction chamber to a pressure of 2-10 Pa. Fill the reaction chamber with H 2 or H 2 and NH3 The pressure of the mixed gas is 0.04-0.1MPa. H in the mixed gas 2 and NH 3 The volume ratio can be 1 / 4 to 4 / 1. Then the above-mentioned anode and the cathode...

Embodiment 1

[0044] Fill Mo powder inside a graphite tube with an outer diameter of 10 mm, an inner diameter of 5 mm, and a length of 16 cm to form an anode, and then fix a cathode graphite rod with a diameter of 6 mm and a length of 14 cm on a water-cooled copper base and face the above-mentioned anode material horizontally. The cavity is evacuated to a pressure of 5Pa and then filled with H 2 The pressure is 0.05MPa, then the anode and the cathode are close to generate arc discharge and plasma (3mm), and the power is turned off after reacting at a current of 50A for 2h, and the reaction product is naturally settled for 2h and collected to obtain the MoC carrier material. Take a certain amount of this carrier material (0.05g) and add 5mL 0.2mmol L -1 H 2 PtCl 6 In the aqueous solution, add 1mL of ethanol dropwise and let stand at room temperature for 12h, then evaporate to dryness at 80°C, grind finely, and then dissolve in 5vol%H 2 / Ar at 350°C for 2 hours to obtain a Pt / MoC catalyst;...

Embodiment 2

[0047] Nb powder is filled inside a graphite tube with an outer diameter of 10 mm, an inner diameter of 5 mm, and a length of 20 cm to form an anode, and then a cathode graphite rod with a diameter of 6 mm and a length of 20 cm is fixed on a water-cooled copper base and is horizontally opposite to the above-mentioned anode material. The cavity is evacuated to a pressure of 4Pa and then filled with hydrogen to a pressure of 0.08MPa, then the anode and cathode are brought close to generate arc discharge and plasma (4mm), and the power is turned off after the reaction at a current of 60A for 2h, and the reaction The product naturally settled for 4h and was collected to obtain the NbC carrier material. Take a certain amount of this carrier material (0.1g) and add 50mL 0.1mmol L -1 H 2 PtCl 6 In the aqueous solution, add 5mL of ethanol dropwise and let stand at room temperature for 20h, then evaporate to dryness at 140°C, grind finely, and then 2 / Ar at 500°C for 2 hours to obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com