Oil rotating spray all-directional blending sweeper

A rotary jet, all-round technology, used in fluid mixers, mixers, cleaning hollow objects, etc., can solve the problems of easily damaged inner floating discs, difficult equipment maintenance, and large safety hazards, so as to achieve less oil loss and improve Turnover utilization, the effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

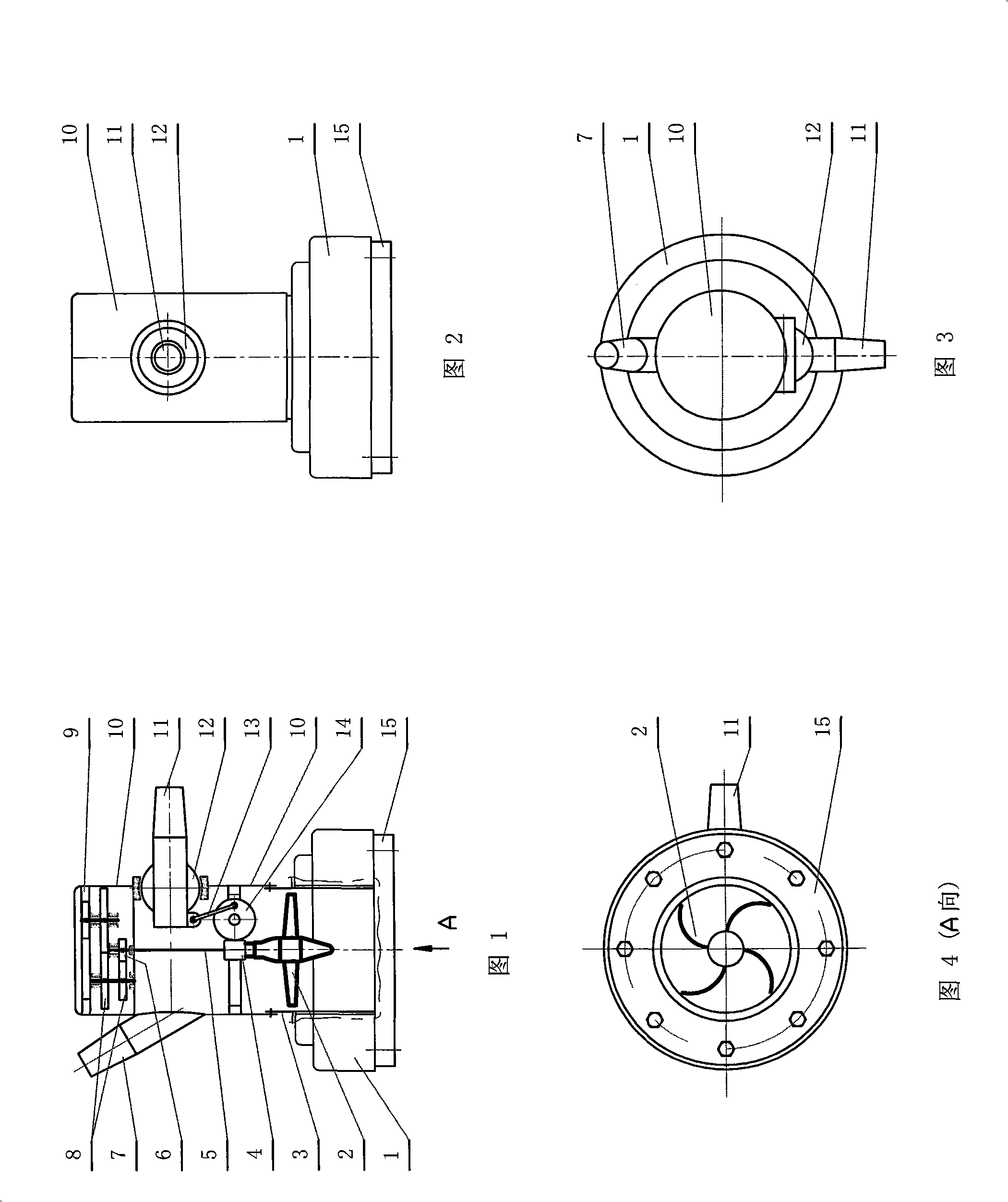

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0018] An example of an embodiment is shown in Figures 1 to 4: an oil rotary jetting omnidirectional blending cleaner, the flange plate 15 on the outside of the base 1 is connected to the oil delivery pipe, and a rotatable inner sleeve 3 is installed on the base 1. The barrel 10 is fastened on the inner sleeve 3, and a reduction box 8 is installed on the upper part of the inner cavity of the rotating barrel 10, and its inner ring gear 9 is fastened on the top of the inner cavity of the rotating barrel 10 and meshes with the final external gear of the reducing box 8 , The primary gear 6 of the reduction box 8 is installed on the upper end of the main shaft 5, and the axial flow turbine 2 is installed at its lower end. A worm 4 is installed on the lower part of the main shaft 5, and the worm gear 14 meshed with it is installed on the mandrel in the middle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com