Concrete side mold and mold support method thereof

A form-supporting method and concrete technology, applied in the direction of road, floor, road repair, etc., can solve the problems of troublesome storage, poor stability of support system, wood consumption, etc., and achieve convenient installation and storage, improve construction quality, and system stability and reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0048] Taking the first embodiment as an example, the formwork support method and storage operation of this embodiment are:

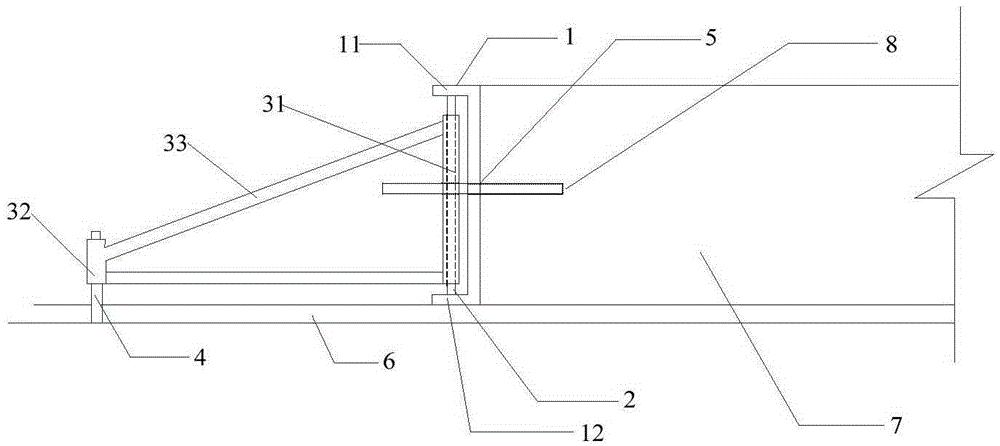

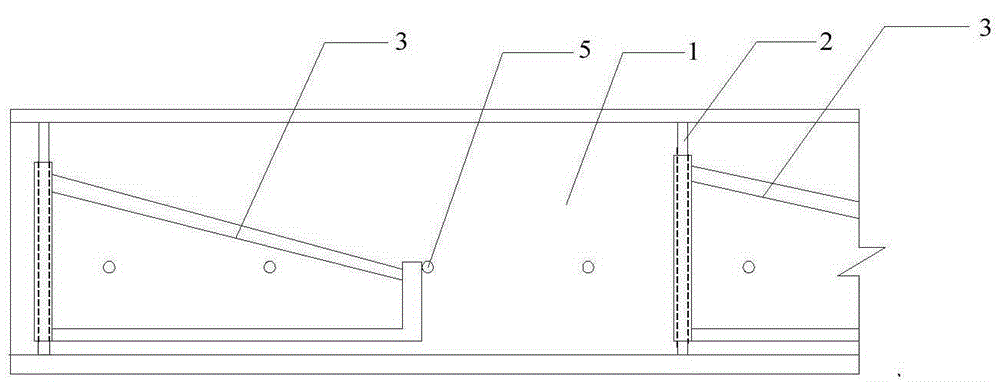

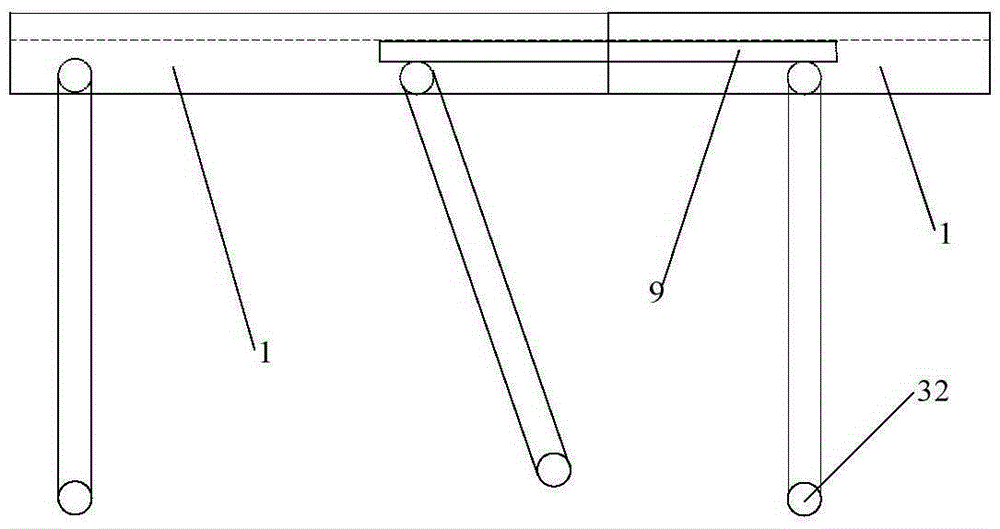

[0049] Such as figure 1 , figure 2 and image 3 As shown, place the side formwork 1 in place according to the sideline position of the road, field or indoor floor; the outer wall of the side formwork 1 is flush with the sideline of the road, field or indoor floor; use the anchor 4 to pass through the fixing piece of the support frame 3 In 32, the basic structure 6 driven into the road, field or indoor floor is used as the final fixation of the side form (preferably, short steel bars can be driven into the basic structure 6 on both sides of the side form 1 in advance for temporary fixation); Joints are formed between the concrete side forms of the present invention, and wooden wedges 9 are clamped between the rotating parts and the side forms on both sides of the joint, so that adjacent concrete side forms are fixed together; after the concrete side f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com