Plywood for panel of as-cast-finish concrete building template

A technology of fair-faced concrete and building formwork, which is applied in the direction of construction, building structure, formwork/formwork components, etc. It can solve the problems of large one-time investment, less turnover times, and heavy weight, and achieve low amortization costs and more turnover times , Durable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

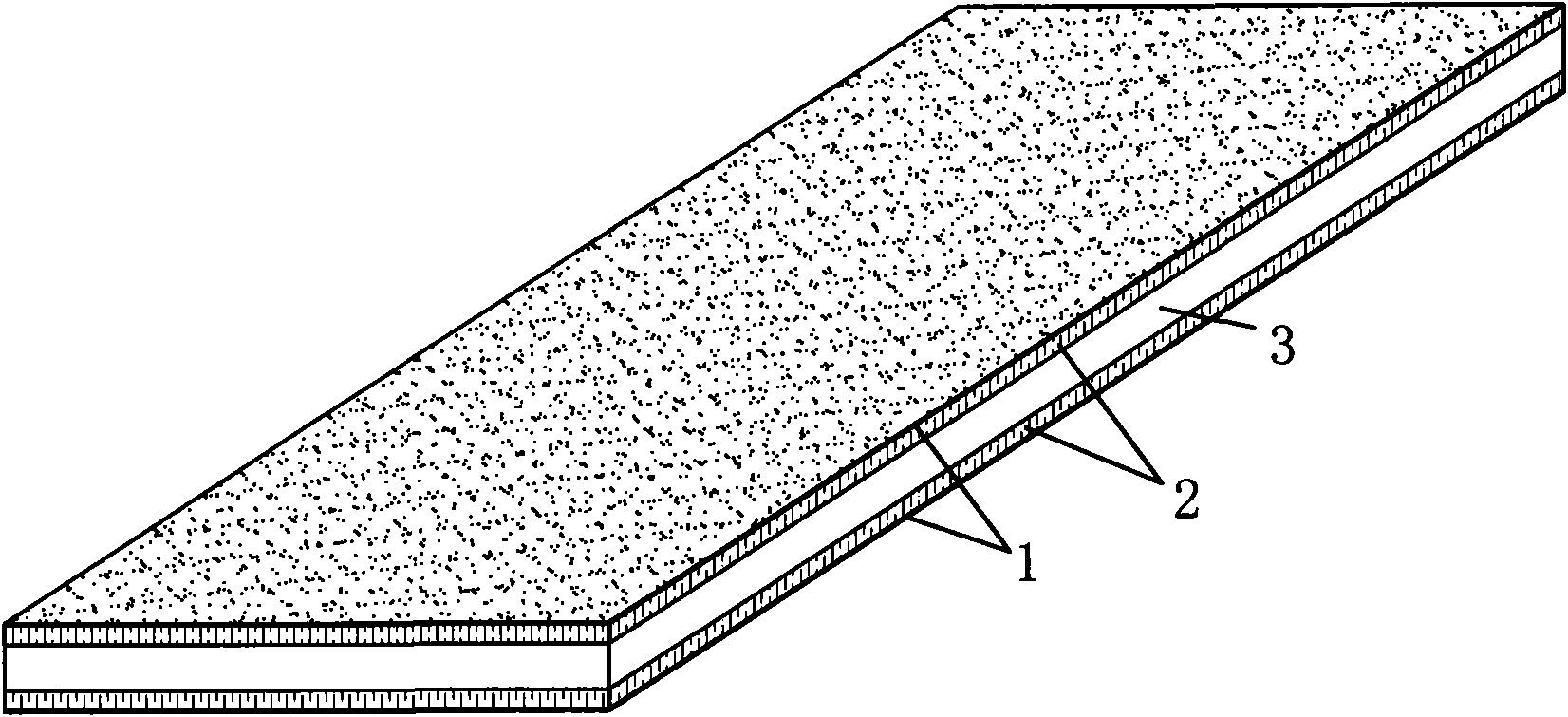

[0020] As shown in the accompanying drawing, a kind of plywood for the panel of fair-faced concrete building formwork comprises a film covering 1, a panel 2 and a core board 3, and the thickness of the plywood is 21mm. The film 1 is a phenolic resin laminated film. According to the requirements of wear resistance, the film weight is 100-400g / m2 on the front side of the plywood. 2 , the opposite side is 100~250g / m 2 ; The thickness of the panel 2 is about 1 ~ 5mm, and the panel 2 is formed by gluing the dipped poplar veneer, the dipped adhesive is a low molecular weight water-soluble phenolic resin (PF), and the thickness of the dipped poplar veneer The thickness of the core board 3 is about 2mm. All adjacent veneers in the plywood are laid vertically to each other, and the plywood cross-section follows the principle of symmetrical laying. The whole plywood can be molded at one time using the traditional plywood process. Finally, paint waterproof paint on the four sides of t...

Embodiment 2

[0022] As shown in the accompanying drawing, a kind of plywood for the panel of fair-faced concrete building formwork comprises a film covering 1, a panel 2 and a core board 3, and the thickness of the plywood is 21mm. The film 1 is a phenolic resin laminated film. According to the requirements of wear resistance, the film weight is 100-400g / m2 on the front side of the plywood. 2 , the opposite side is 100~250g / m 2 ; The thickness of the panel 2 is about 1 ~ 5mm, and the panel 2 is formed by gluing the dipped poplar veneer, the dipped adhesive is a low molecular weight water-soluble phenolic resin (PF), and the thickness of the dipped poplar veneer It is about 1 mm; the core board 3 is a masson pine laminated board. All adjacent veneers in the plywood are laid perpendicularly to each other, the direction of the glulam in the core board along the grain is perpendicular to the support direction of the panel in the formwork system, and the principle of symmetrical layering is fo...

Embodiment 3

[0024] As shown in the accompanying drawing, a kind of plywood for the panel of fair-faced concrete building formwork comprises a film covering 1, a panel 2 and a core board 3, and the thickness of the plywood is 21mm. The film 1 is a phenolic resin laminated film. According to the requirements of wear resistance, the film weight is 100-400g / m2 on the front side of the plywood. 2 , the opposite side is 100~250g / m 2 ; The thickness of the panel 2 is about 1 ~ 5mm, and the panel 2 is formed by gluing the dipped poplar veneer, the dipped adhesive is a low molecular weight water-soluble phenolic resin (PF), and the thickness of the dipped poplar veneer about 1 mm; the core board 3 is formed by laying ordinary poplar veneers and dipped poplar veneers alternately, wherein the dipped poplar veneers can be laid every 1 to 3 layers of common poplar veneers. Zhang, the thickness of the veneer in the core board 3 is about 2mm. All adjacent veneers in the plywood are laid vertically to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com