Comprehensive use method of mixed C-4

A technology of mixing carbon 4 and mixture, which is applied in the field of comprehensive utilization of mixed carbon 4, can solve the problem of low comprehensive utilization rate of mixed carbon 4, and achieve the effect of increasing value and good technical effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

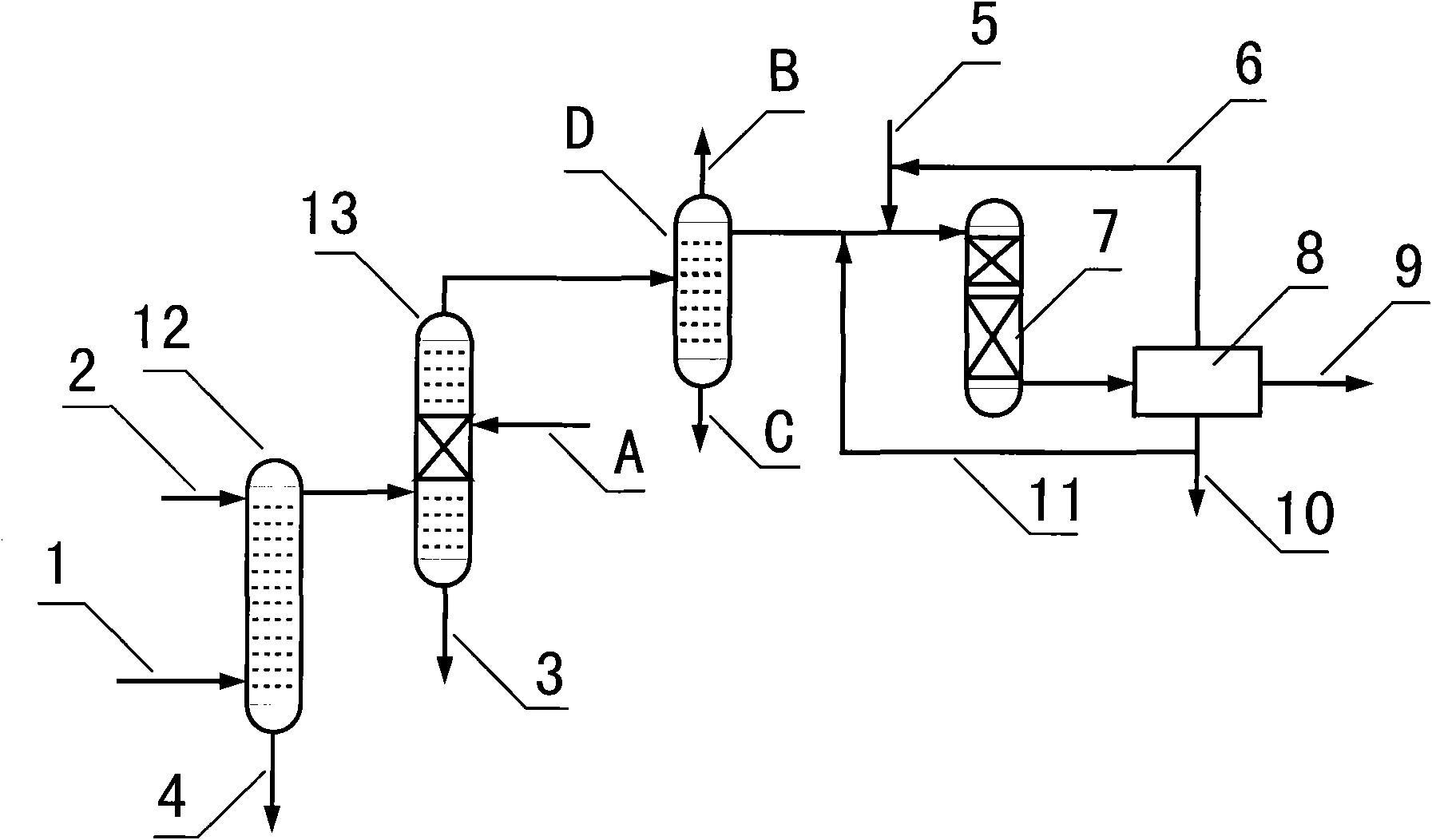

[0027] according tofigure 1 As shown, the mixed C4 composition (% by weight) is: butadiene: 40.0%, isobutene: 12.0%, butene-1: 18.0%, butene-2: 18.2%, butane: 11.8%. According to the technical process of the present invention, acetonitrile is used as the extraction agent 2; as described in the background art, the extraction and extraction of butadiene unit includes an extraction column, a water washing column, a rectification column (2) and a rectification column (3). The extraction tower is a valve tower with 60 plates and the operating pressure at the top of the tower is 0.45MPa; the washing tower is a valve tower with 50 plates and the operating pressure at the top of the tower is 0.6MPa; the rectification tower (2) is a float The valve column has 40 plates and the operating pressure at the top of the column is 0.5MPa; the rectification column (3) is a valve column with 60 plates and the operating pressure at the top of the column is 0.8MPa. The etherification unit includes...

Embodiment 2

[0029] according to figure 1 As shown, the mixed C4 composition (% by weight) is: butadiene: 30.0%, isobutene: 12.0%, butene-1: 18.0%, butene-2: 18.2%, butane: 21.8%. According to the technological process of the present invention, the extraction agent 2 adopts dimethylformamide; as described in the background art, the extraction and extraction of butadiene unit includes an extraction column, a water washing column, a rectification column (2) and a rectification column (3). The extraction tower is a sieve tray column, the number of trays is 80, and the operating pressure at the top of the tower is 0.65MPa; the washing tower is a sieve tray tower, the number of trays is 60, and the operating pressure at the top of the tower is 0.4MPa; the rectification tower (2) is a sieve tray The plate column has 50 plates and the operating pressure at the top of the column is 0.6MPa; the rectifying column (3) is a sieve plate column, the number of plates is 80, and the operating pressure at ...

Embodiment 3

[0031] according to figure 1 As shown, the mixed C4 composition (% by weight) is: butadiene: 20.0%, isobutene: 15.0%, butene-1: 18.0%, butene-2: 18.2%, butane: 28.8%. According to the technical process of the present invention, acetonitrile is used as the extraction agent 2; as described in the background art, the extraction and extraction of butadiene unit includes an extraction column, a water washing column, a rectification column (2) and a rectification column (3). The extraction tower is a packed tower, the packing height is 30 meters, and the operating pressure at the top of the tower is 0.55MPa; the water washing tower is a packed tower, the packing height is 20, and the operating pressure at the top of the tower is 0.5MPa; the rectification tower (2) is a valve tower, The number of plates is 43, and the operating pressure at the top of the tower is 0.55 MPa; the rectification tower (3) is a packed tower, the height of the packing is 22 meters, and the operating pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com