Continuous synthesis method for methyl methoxyacetate

A technology of methyl methoxyacetate and synthesis method, which is applied in the direction of carbon monoxide or formate reaction preparation, climate sustainability, sustainable manufacturing/processing, etc., and can solve the problem of large amount of wastewater treatment, difficult product separation, and unfavorable industrialization Production and other issues, to achieve the effect of low-cost large-scale industrialization, simple operation mode, and significant cost advantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

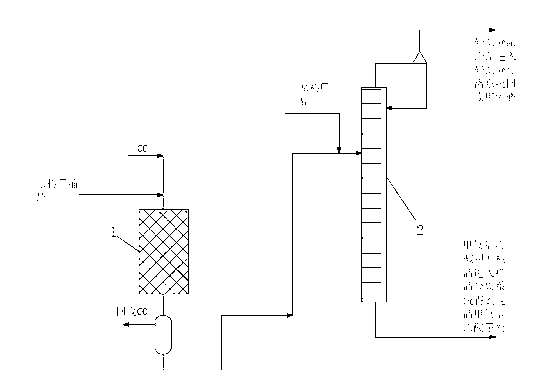

[0039] The technological process of the continuous synthesis method of methyl methoxyacetate is as figure 1 As shown, in the carbonylation reaction section: 85%wt methylal containing methanol and CO are mixed according to the molar ratio of methylal / CO of 1:1, and the weight ratio of methylal to reaction solvent is 1:1, according to The flow rate of methylal is 30ml / h, and it is continuously pumped into carbonylation reactor 1 equipped with a solid catalyst. The reaction temperature in carbonylation reactor 1 is 100°C and the reaction pressure is 3MPa. After the carbonylation reaction, the methylal The conversion rate is 82.35%wt, no products such as CO2 have been detected, relative to the converted methylal, the selectivity of methyl methoxyacetate is 60.56% mole, and the selectivity of methyl glycolate is 15.34% mole, The high boiling point polyester selectivity is 6.75% mole. In the catalytic rectification reaction section: the carbonylation reaction liquid and anhydrous m...

Embodiment 2

[0041] The technological process of the continuous synthesis method of methyl methoxyacetate is as figure 1As shown, in the carbonylation reaction section: 99.5%wt of methylal and CO are mixed according to the molar ratio of methylal / CO of 1:3, and the weight ratio of methylal to reaction solvent is 4:1. The flow rate is 30ml / h, and it is continuously pumped into the carbonylation reactor 1 equipped with a solid catalyst. The reaction temperature in the carbonylation reactor 1 is 150°C, and the reaction pressure is 10MPa. After the carbonylation reaction, the conversion rate of methylal It is 100%wt, and no products such as CO2 have been detected. Compared with the converted methylal, the selectivity of methyl methoxyacetate is 66.78% mole, and the selectivity of methyl glycolate is 1.23% mole. The ester selectivity is 23.58% mole. In the catalytic rectification reaction section: the carbonylation reaction liquid and anhydrous methanol are continuously fed into the catalytic ...

Embodiment 3

[0043] The technological process of the continuous synthesis method of methyl methoxyacetate is as figure 1 As shown, in the carbonylation reaction section: 99.5%wt of methylal and CO are continuously pumped at a methylal / CO molar ratio of 1:3, without using a reaction solvent, at a flow rate of 30ml / h of methylal In the carbonylation reactor 1 equipped with a solid catalyst, the reaction temperature in the carbonylation reactor 1 is 110°C, and the reaction pressure is 4MPa. After the carbonylation reaction, the conversion rate of methylal is 99.8%wt, and no CO2 is detected And other products, relative to the converted methylal, the selectivity of methyl methoxyacetate is 67.96% mole, the selectivity of methyl glycolate is 0.93% mole, and the selectivity of high boiling point polyester is 24.78% mole. In the catalytic rectification reaction section: the carbonylation reaction liquid and anhydrous methanol are continuously fed into the catalytic rectification tower 2 at a weigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com