Method for preparing neopentylene glycol

A technology of neopentyl glycol and hydroxypivalaldehyde, applied in chemical instruments and methods, preparation of hydroxyl compounds, preparation of organic compounds, etc., can solve the problems of polluting the environment, high catalyst prices, rising production costs, etc. big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

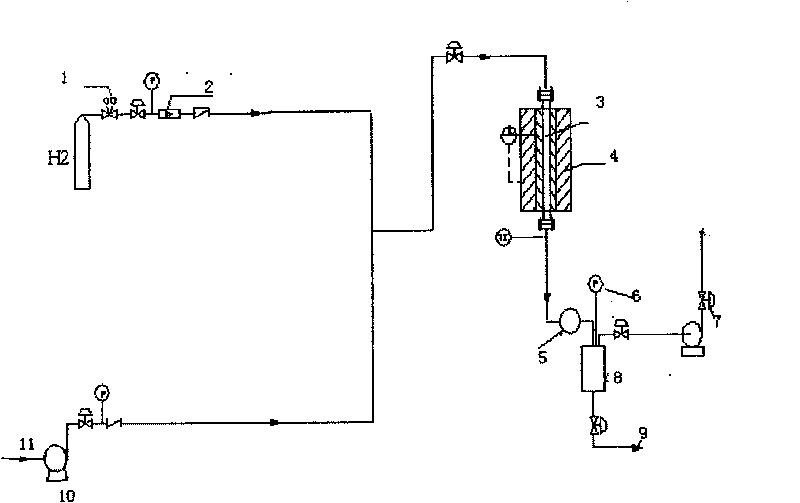

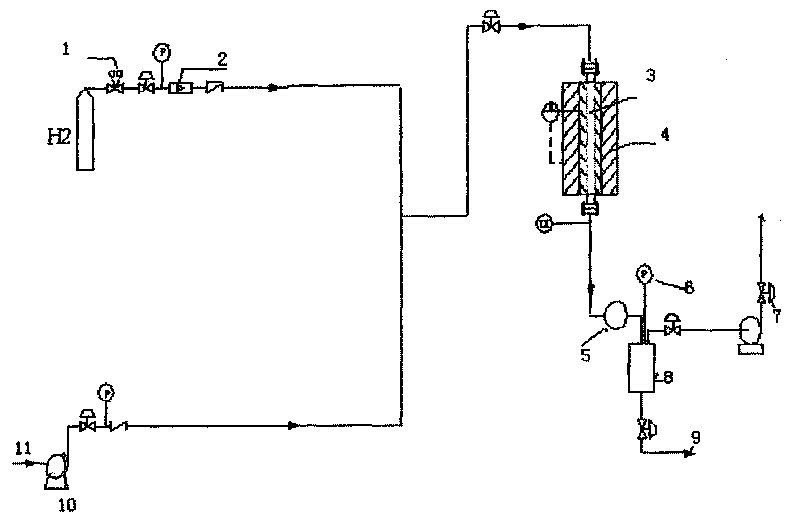

Method used

Image

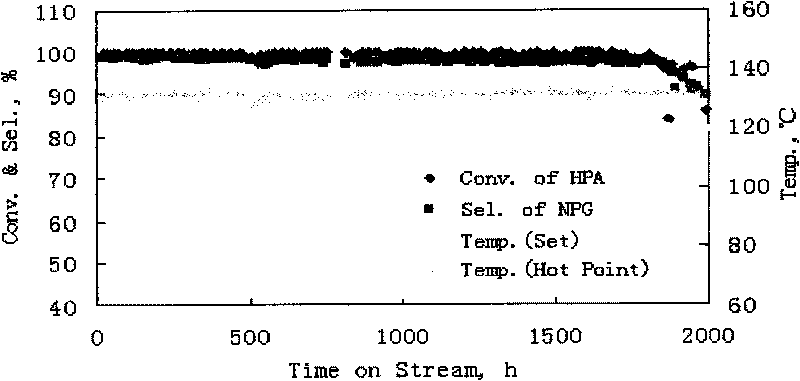

Examples

Embodiment 1

[0020]Prepare 500ml of 2mol / L mixed solution of copper nitrate, zinc nitrate and aluminum nitrate, gradually add alkaline precipitant such as dilute ammonia solution 200ml at 60°C, and keep stirring the system to make the active components precipitate uniformly, filter the precipitate, Washing, drying at 100°C, tablet molding, and calcination at 400°C to obtain the Cu-Zn-Al catalyst precursor. Reduction conditions: In hydrogen atmosphere, rise from room temperature to 120°C at 1°C / min, stay for 2 hours, then rise to 140°C at 0.5°C / min, stay for 2 hours, then rise to 180°C at 0.5°C / min, Stay for 4 hours, lower the temperature, hydrogen pressure 0.3MPa; hydrogen flow rate 50ml / min. The reaction conditions and results of the Cu-Zn-Al catalyst are shown in Table 1, and the solvent used in the reaction is ethanol.

[0021] Table 1 Reaction performance of Cu-Zn-Al catalyst

[0022]

Embodiment 2

[0024] Prepare 500ml of 2mol / L mixed solution of copper nitrate, chromium nitrate and aluminum nitrate, gradually add alkaline precipitant such as dilute ammonia solution 200ml at 60°C, and keep stirring the system to make the active components evenly precipitate, filter the precipitate, Washing, drying at 100°C, adding 5% methyl cellulose to extrusion molding, and calcination at 400°C to obtain the Cu-Cr-Al catalyst precursor. Reduction conditions: Under hydrogen atmosphere, rise from room temperature to 120°C at 1°C / min, stay for 2 hours, then rise to 140°C at 0.5°C / min, stay for 2 hours, then rise to 200°C at 0.5°C / min, Stay for 4 hours, lower the temperature, hydrogen pressure 0.3MPa; hydrogen flow rate 50ml / min. The reaction conditions and results of the Cu-Cr-Al catalyst are shown in Table 2, and the solvent used in the reaction is methanol.

[0025] Table 2 Reaction performance of Cu-Cr-Al catalyst

[0026]

Embodiment 3

[0028] Prepare 100ml of 2mol / L copper nitrate and chromium nitrate mixed solution, gradually add 30g of formed γ-alumina carrier at 70°C, so that the active components are evenly loaded on γ-alumina, and place the mixed system at 80°C Stir and heat in a water bath to volatilize the solvent, dry at 100°C, and bake at 400°C to obtain the CuCr / alumina catalyst precursor. Reduction conditions: Under hydrogen atmosphere, rise from room temperature to 120°C at 1°C / min, stay for 2 hours, then rise to 140°C at 0.5°C / min, stay for 2 hours, then rise to 240°C at 0.5°C / min, Stay for 4 hours, lower the temperature, hydrogen pressure 0.3MPa; hydrogen flow rate 50ml / min. The reaction conditions and results of the CuCr / alumina catalyst are shown in Table 3, and the solvent used in the reaction is butanol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com