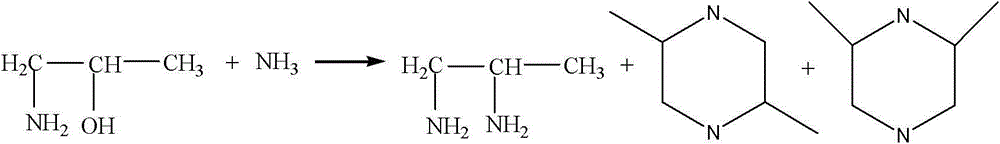

A method of preparing 1,2-diaminopropane from isopropanolamine and liquid ammonia and a device thereof

A technology of isopropanolamine and propylenediamine, which is applied in the preparation of amino compounds, chemical instruments and methods, and the preparation of organic compounds, can solve the problems of unfavorable industrial production of the preparation method, low selectivity of 1,2-propylenediamine, Catalyst and product separation difficulties and other problems, to achieve the effect of large-scale continuous industrial production, improve selectivity, reduce one-time investment and production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

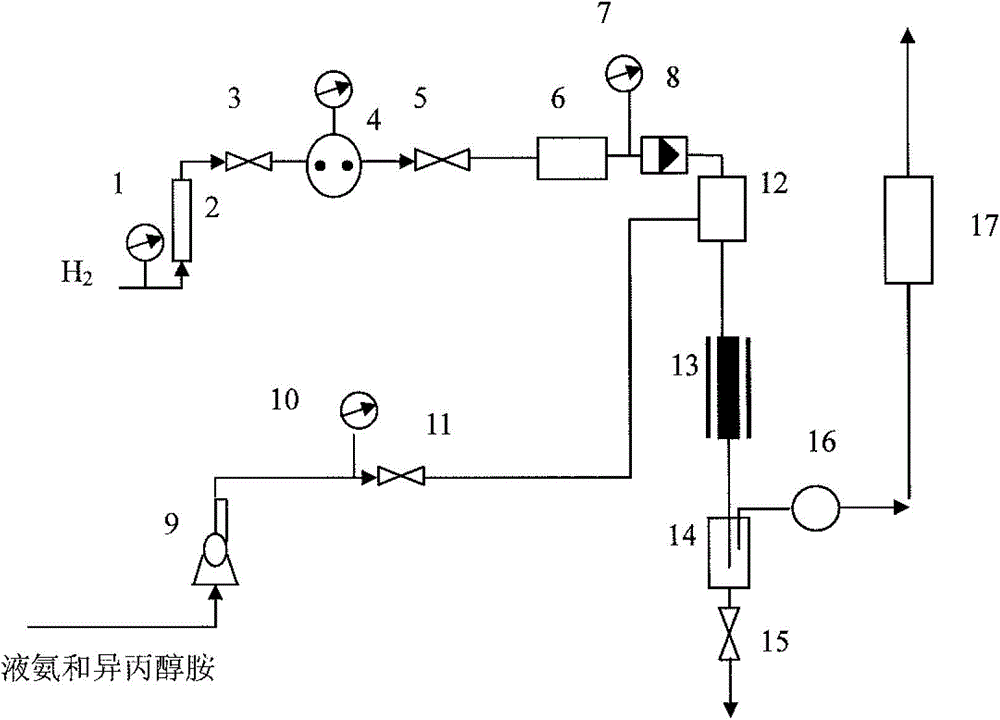

Method used

Image

Examples

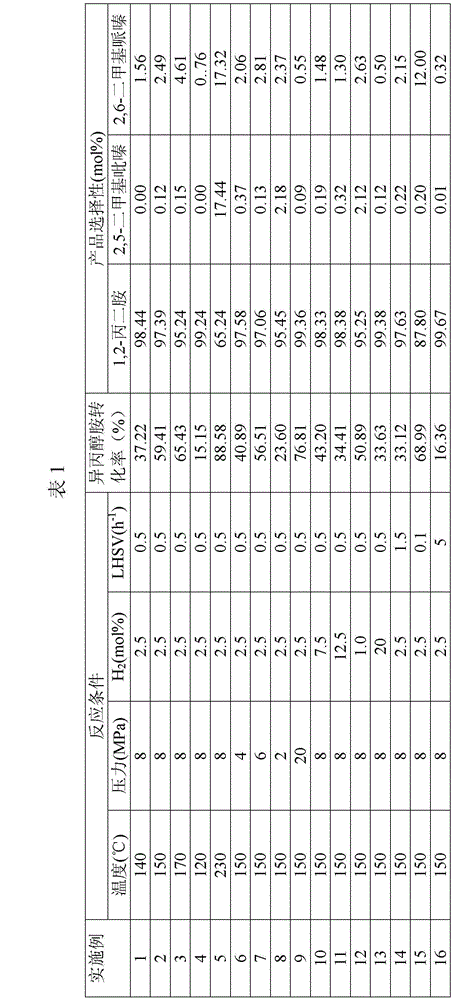

Embodiment 1

[0050] Weigh the above 15%Ni-1.6%Re-1.2%B / Al 2 O 3 The catalyst, 3.2 grams (about 4 ml), was charged into the fixed bed reactor. The catalyst is activated by hydrogenation before use. The activation conditions are: temperature T=375℃; pressure P=normal pressure, gas volume space velocity GHSV=2000h -1 , the restoration time is 4 hours. When the temperature in the reactor is naturally cooled to 140 °C, the pressure is increased to 8MPa. After the system is stabilized, the liquid ammonia / isopropanolamine = 10 (molar ratio) is pumped into the reactor to adjust the isopropanolamine. The volumetric space velocity of the liquid is 0.5h -1 , the H2 content in the reaction system was 2.5 mol%, the reaction was carried out, the reaction time was 50 hours, and the sample was taken for analysis. SE-30 capillary chromatographic column, FID detector, N,N-dimethylformamide as internal standard for quantitative analysis, the reaction results are shown in Table 1. The product can be dist...

Embodiment 2

[0051] Weigh the above 15%Ni-1.6%Re-1.2%B / Al 2 O 3 The catalyst, 3.2 grams (about 4 ml), was charged into the fixed bed reactor. The catalyst is activated by hydrogenation treatment before use, and the activation conditions are: T=375℃; P=normal pressure, GHSV=2000h -1 , the restoration time is 4 hours. When the temperature in the reactor is naturally cooled to 150 °C, the pressure is increased to 8MPa. After the system is stabilized, the liquid ammonia / isopropanolamine = 10 (molar ratio) is pumped into the reactor to adjust the isopropanolamine. The volumetric space velocity of the liquid is 0.5h -1 , H in the reaction system 2 The content was 2.5 mol%, the reaction was carried out, and the reaction time was 50 hours, and the samples were taken for analysis. SE-30 capillary chromatographic column, FID detector, N,N-dimethylformamide as internal standard for quantitative analysis, the reaction results are shown in Table 1.

Embodiment 3

[0053] Weigh the above 15%Ni-1.6%Re-1.2%B / Al 2 O 3 The catalyst, 3.2 grams (about 4 ml), was charged into the fixed bed reactor. The catalyst is activated by hydrogenation treatment before use, and the activation conditions are: T=375℃; P=normal pressure, GHSV=2000h -1 , the restoration time is 4 hours. When the temperature in the reactor is naturally cooled to 170°C, the pressure is increased to 8MPa. After the system is stabilized, the liquid ammonia / isopropanolamine = 10 (molar ratio) is pumped into the reactor to adjust the isopropanolamine. The volumetric space velocity of the liquid is 0.5h -1 , H in the reaction system 2 The content was 2.5 mol%, the reaction was carried out, and the reaction time was 50 hours, and the samples were taken for analysis. SE-30 capillary chromatographic column, FID detector, N,N-dimethylformamide as internal standard for quantitative analysis, the reaction results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com