Process for preparing pentane from light C5 distillate

A technology for carbon five fraction and pentane, which is applied in the field of pentane preparation, can solve the problems of affecting service performance, incomplete hydrogenation of straight-run gasoline, complex composition of condensate and light naphtha, etc. The effect of improving the value of economic use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~17

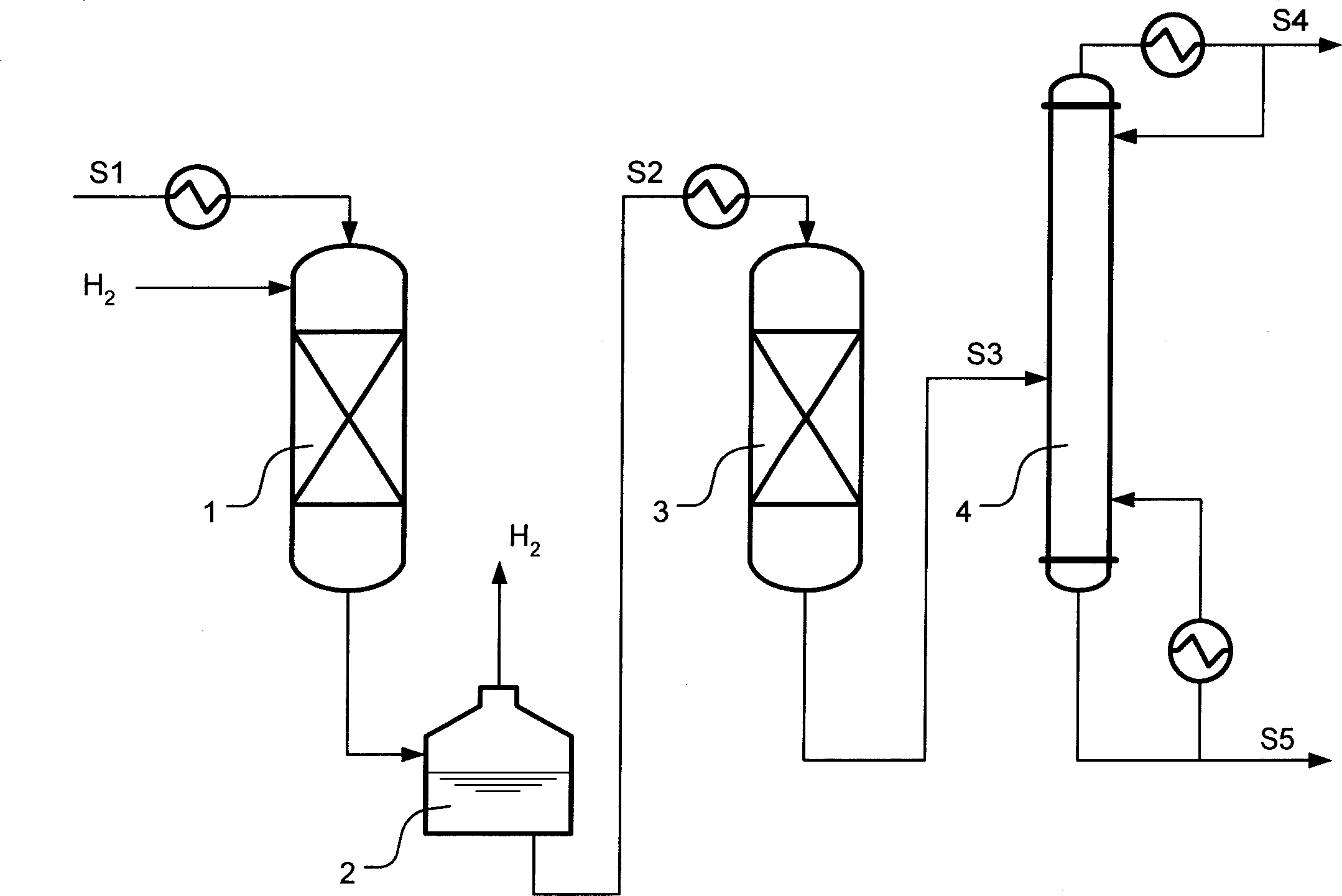

[0029] The technological process of the preparation process is shown in the accompanying drawing.

[0030] Among them, the hydrogenation reactor 1 is a stainless steel tubular reactor, including a reaction tube of φ25mm×1000mm, filled with 100ml of catalyst in the reaction tube, and the catalyst uses Ni as the active component, Al 2 o 3 with SiO 2 The mixture is used as a carrier, and the Ni content is 30-55wt%. The bottom of the reactor is filled with inert ceramic balls.

[0031] Adsorption reactor 2 is a stainless steel tubular reactor, including a φ25mm×1000mm reaction tube, filled with granular clay, the granular clay has a particle size of 20-60 mesh, acidity ≤ 2.5KOHmg / g, and a packing density of 0.65- 0.70g / ml.

[0032] After being preheated, the light C5 fraction material S1 is sent to the hydrogenation reactor 1 from the top at a set rate by a pump, and the hydrogen enters the reactor through the gas distributor, and the light C5 fraction material is mixed with h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bronsted acidity | aaaaa | aaaaa |

| bromine number | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com