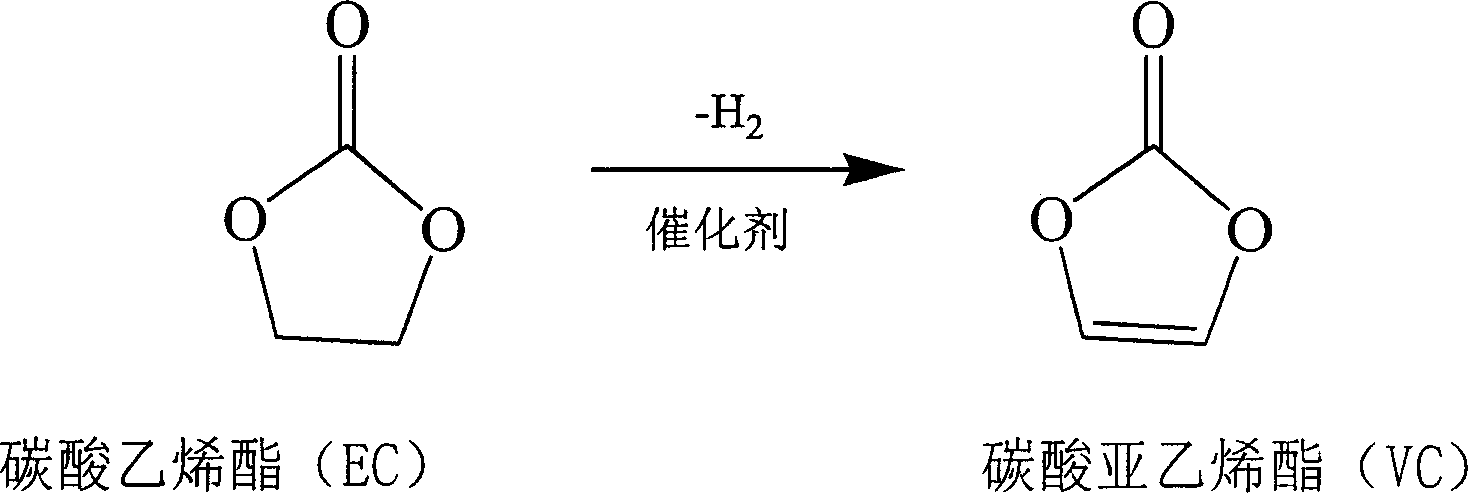

Process for synthesizing vinylene carbonate

A technology of vinylene carbonate and alloy, applied in the field of synthesis of vinylene carbonate, can solve problems such as complex process, prone to danger, environmental pollution, etc., and achieve the effect of simple reaction process, easy industrial scale-up, and remarkable economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] al 2 o 3 The carrier was crushed and sieved, and 20-40 meshes were selected. After activation at 500°C for two hours, the iron catalyst was loaded on Al 2 o 3 On the carrier, get Fe 2 o 3 with Al 2 o 3 The mass ratio of the catalyst is 1:4. Add the catalyst into the fixed-bed reactor, and ethylene carbonate (EC) is continuously fed into the micro-fixed-bed reactor at a space velocity of 2 g / h mlcat. with a micro-injection pump. The reaction temperature is 360 °C and the reaction pressure is 0.2 MPa, at the same time, nitrogen was introduced as carrier gas and protective gas for reaction. The reaction product was collected by a condensing device and analyzed by gas chromatography. The yield of vinylene carbonate (VC) was 60%.

Embodiment 2

[0021] Other conditions are as example 1, add K 2 O (2%) co-catalyst, vinylene carbonate (VC) yield is 70%.

Embodiment 3

[0023] Other conditions are as in Example 1, adding 3% of Li(OH) cocatalyst, and the yield of vinylene carbonate (VC) is 69%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com