Preparation method of modified silicon powder

A technology of modifying silicon and silicon powder, which is applied in the field of preparation of construction materials, can solve the problems of poor dispersion and easy aggregation of silicon powder, and achieve the effects of easy separation, increased flexural strength, and solution to agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

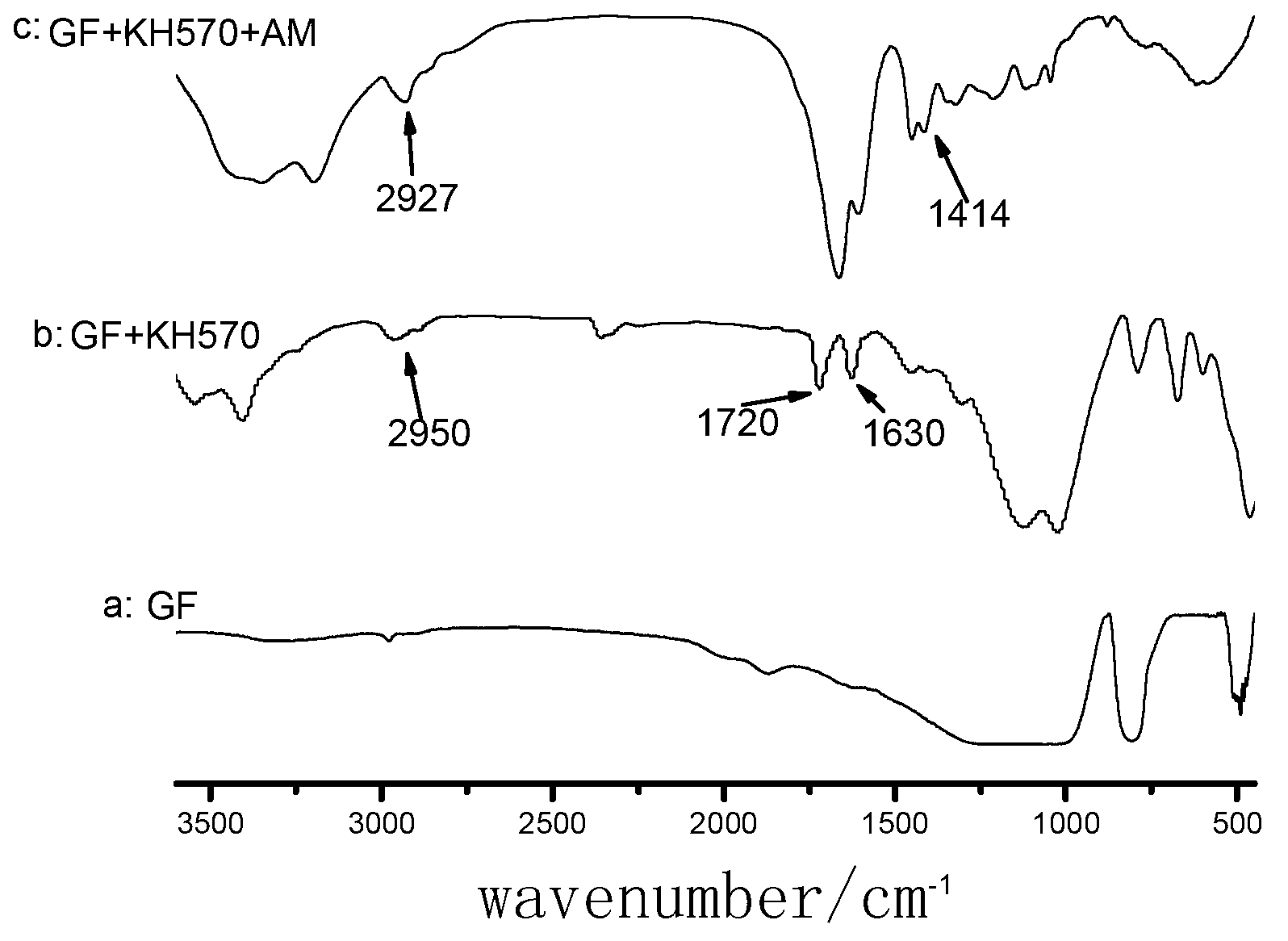

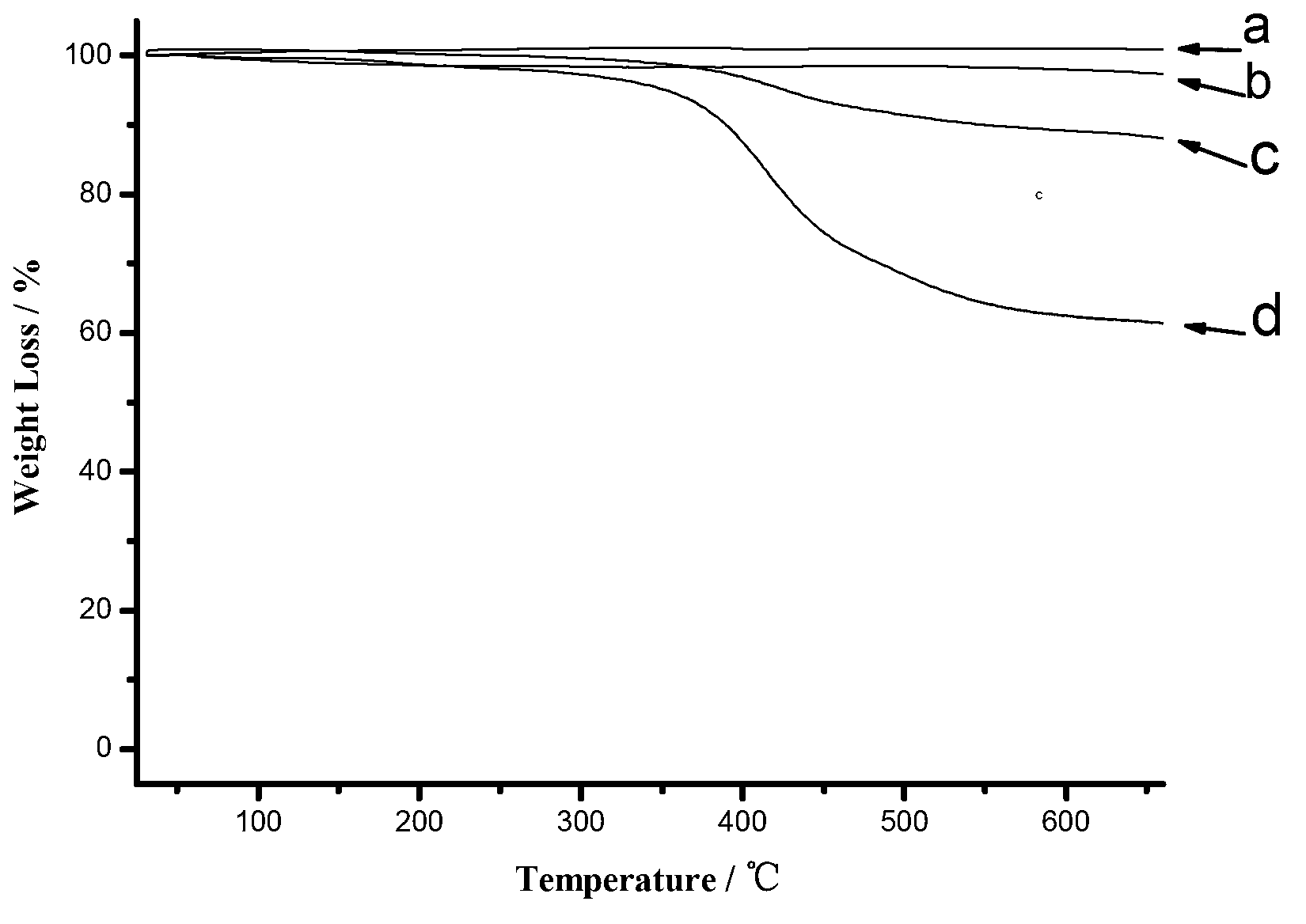

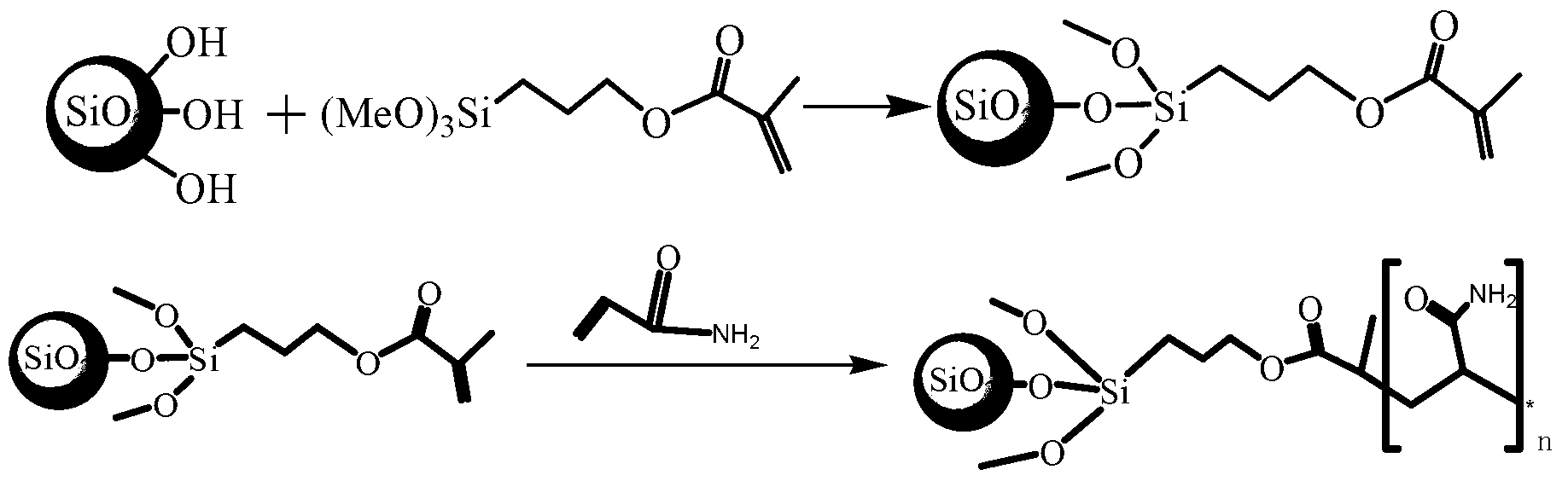

Method used

Image

Examples

Embodiment 1

[0020] 1. Add silicon powder to absolute ethanol, ultrasonically disperse for 30 minutes and then centrifuge, repeat ultrasonically disperse and centrifuge 3 times, then add distilled water, ultrasonically disperse for 15 minutes and then centrifuge, repeat ultrasonically disperse and centrifuge 3 times, after vacuum drying Get pretreated silicon powder. The purpose of pretreatment is to remove impurities, activate and disperse the particles of silicon powder evenly.

[0021] 2. Slowly pour the pretreated silicon powder into a sodium hydroxide solution with a mass concentration of 20%, while continuously stirring and reacting for 24 hours, filter under reduced pressure, wash with distilled water until the pH is 8-9 to obtain alkali-treated silicon powder; The treated silicon powder was poured into a sulfuric acid solution with a mass concentration of 10%, stirred continuously for 4 hours, filtered under reduced pressure, washed with distilled water until neutral, and vacuum-dr...

Embodiment 2

[0025] 1. Add silicon powder to absolute ethanol, ultrasonically disperse for 30 minutes and then centrifuge, repeat ultrasonically disperse and centrifuge 3 times, then add distilled water, ultrasonically disperse for 15 minutes and then centrifuge, repeat ultrasonically disperse and centrifuge 3 times, after vacuum drying Get pretreated silicon powder. The purpose of pretreatment is to remove impurities, activate and disperse the particles of silicon powder evenly.

[0026]2. Slowly pour the pretreated silicon powder into a sodium hydroxide solution with a mass concentration of 20%, while continuously stirring and reacting for 24 hours, filter under reduced pressure, wash with distilled water until the pH is 8-9 to obtain alkali-treated silicon powder; The treated silicon powder was poured into a sulfuric acid solution with a mass concentration of 10%, stirred continuously for 4 hours, filtered under reduced pressure, washed with distilled water until neutral, and vacuum-dri...

Embodiment 3

[0030] 1. Add silicon powder to absolute ethanol, ultrasonically disperse for 30 minutes and then centrifuge, repeat ultrasonically disperse and centrifuge 3 times, then add distilled water, ultrasonically disperse for 15 minutes and then centrifuge, repeat ultrasonically disperse and centrifuge 3 times, after vacuum drying Get pretreated silicon powder. The purpose of pretreatment is to remove impurities, activate and disperse the particles of silicon powder evenly.

[0031] 2. Slowly pour the pretreated silicon powder into a sodium hydroxide solution with a mass concentration of 20%, while continuously stirring and reacting for 24 hours, filter under reduced pressure, wash with distilled water until the pH is 8-9 to obtain alkali-treated silicon powder; The treated silicon powder was poured into a sulfuric acid solution with a mass concentration of 10%, stirred continuously for 4 hours, filtered under reduced pressure, washed with distilled water until neutral, and vacuum-dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com