Method for preparing water-based urethane acrylate pressure-sensitive adhesive

A urethane acrylate and pressure-sensitive adhesive technology, applied in the directions of graft polymer adhesives, adhesive types, adhesives, etc. It is difficult to completely polymerize and other problems to achieve the effects of reducing industrial costs, improving solvent resistance and improving conversion rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

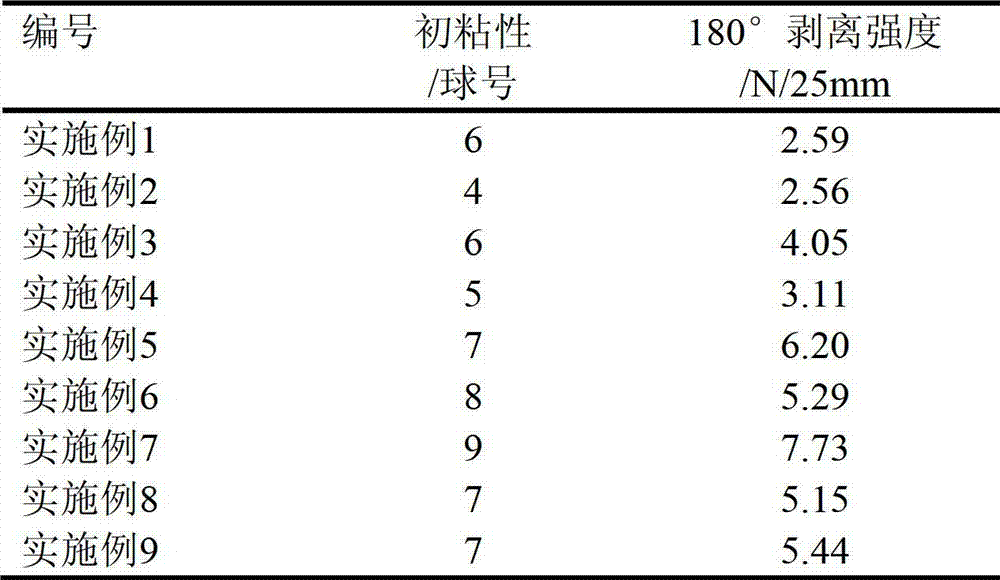

Examples

Embodiment 1

[0030] Example 1: (where: R 1 The value is 1.2, R 2 The value is 1, the mass fraction of DMPA is 8%, the neutralization degree is 100%, and the mass fraction of acrylate is 90%)

[0031] (A) Preparation of aqueous polyurethane emulsion

[0032] Take 0.025mol of polypropylene glycol-1000 (PPG-1000) and 0.022mol of dimethylolpropionic acid (DMPA) into a four-neck flask equipped with stirring and raise the temperature to 140°C, dehydrate, and after about 10min, cool down to 60°C , add 0.0564mol of TDI, raise the temperature to 80°C, keep the temperature for 2.5h, stop heating, naturally cool down to 70°C, add 1.222g of hydroxypropyl acrylate (HPA), and react for about 2h. After the end-capping reaction, add methyl ethyl ketone to adjust the viscosity, the mass of methyl ethyl ketone is 60% of the mass of polypropylene glycol, add 0.022mol triethylamine, stir for about 10 minutes, add polyurethane prepolymer to 155g water for dispersion and chain extension for about 2 hours, and...

Embodiment 2

[0035] Example 2: (where R 1 The value is 1.4, R 2 The value is 1, the mass fraction of DMBA is 7%, the neutralization degree is 80%, and the mass fraction of acrylate is 15%)

[0036] (A) Preparation of aqueous polyurethane emulsion

[0037]Take 0.025mol of polypropylene glycol-2000 (PPG-2000) and 0.022mol of dimethylol butyric acid (DMBA) into a four-neck flask equipped with stirring and raise the temperature to 160°C for dehydration. After about 15 minutes, cool down to 50°C , add 0.065mol of MDI, raise the temperature to 90°C, keep the temperature for 2h, stop heating, naturally cool down to 70°C, add 2.34g of hydroxyethyl methacrylate (HEMA), and react for about 2h. After the end-capping reaction, add acetone to adjust the viscosity, the mass of acetone is 70% of the mass of polypropylene glycol, add 0.0176mol dimethylethanolamine, stir for about 10min, add the polyurethane prepolymer to 158g of water for about 3h to disperse and extend the chain, and obtain a water-bas...

Embodiment 3

[0040] Example 3: (wherein R 1 The value is 1.4, R 2 The value is 1.1, the mass fraction of 1,4-butanediol-2-sodium sulfonate is 10.5%, the neutralization degree is 86%, and the mass fraction of acrylate is 45%)

[0041] (A) Preparation of aqueous polyurethane emulsion

[0042] Take 0.025mol of polyethylene glycol-2000 (PEG-2000) and 0.022mol of 1,4-butanediol-2-sodium sulfonate into a four-necked flask equipped with stirring and heat up to 150°C, dehydrate, after about 10min , cool down to 65°C, add 0.065mol of hexamethylene diisocyanate (HDI), raise the temperature to 85°C, keep the temperature for 2.5h, stop heating, naturally cool down to 70°C, add 1.17g of hydroxypropyl methacrylate (HPMA) , The reaction is about 3h. After the end-capping reaction, add tetrahydrofuran to adjust the viscosity. The mass of tetrahydrofuran is 80% of the mass of polyethylene glycol. Add 0.0189mol diethanolamine and stir for about 20 minutes. Add the polyurethane prepolymer to 157g water fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com