High-frequency pulse pinking engine and control method thereof

A detonation engine and high-frequency pulse technology, which is applied to machines/engines, rocket engine devices, mechanical equipment, etc., can solve the problems of cycle efficiency and exhaust noise that are difficult to improve, and achieve the effect of reducing exhaust noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

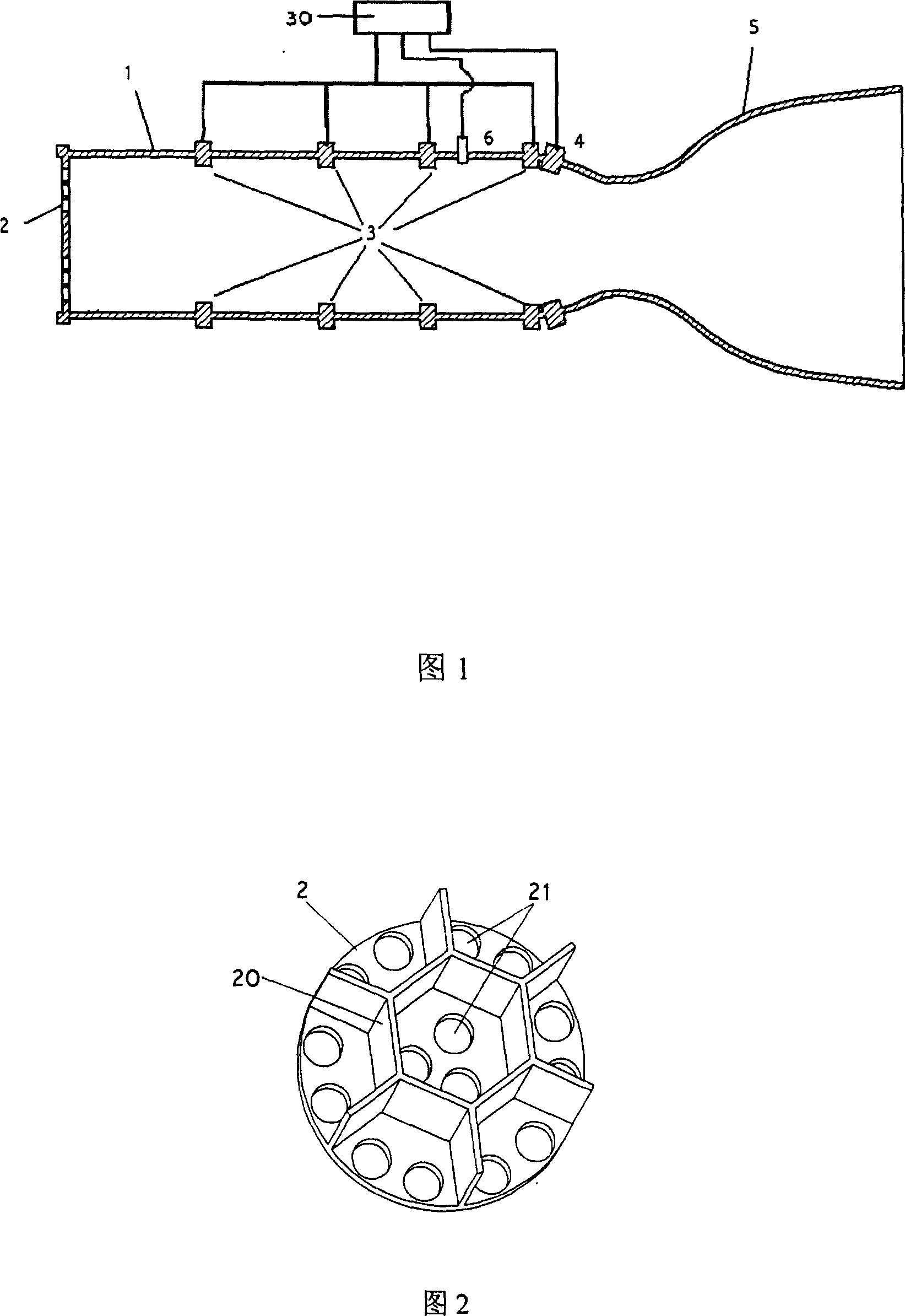

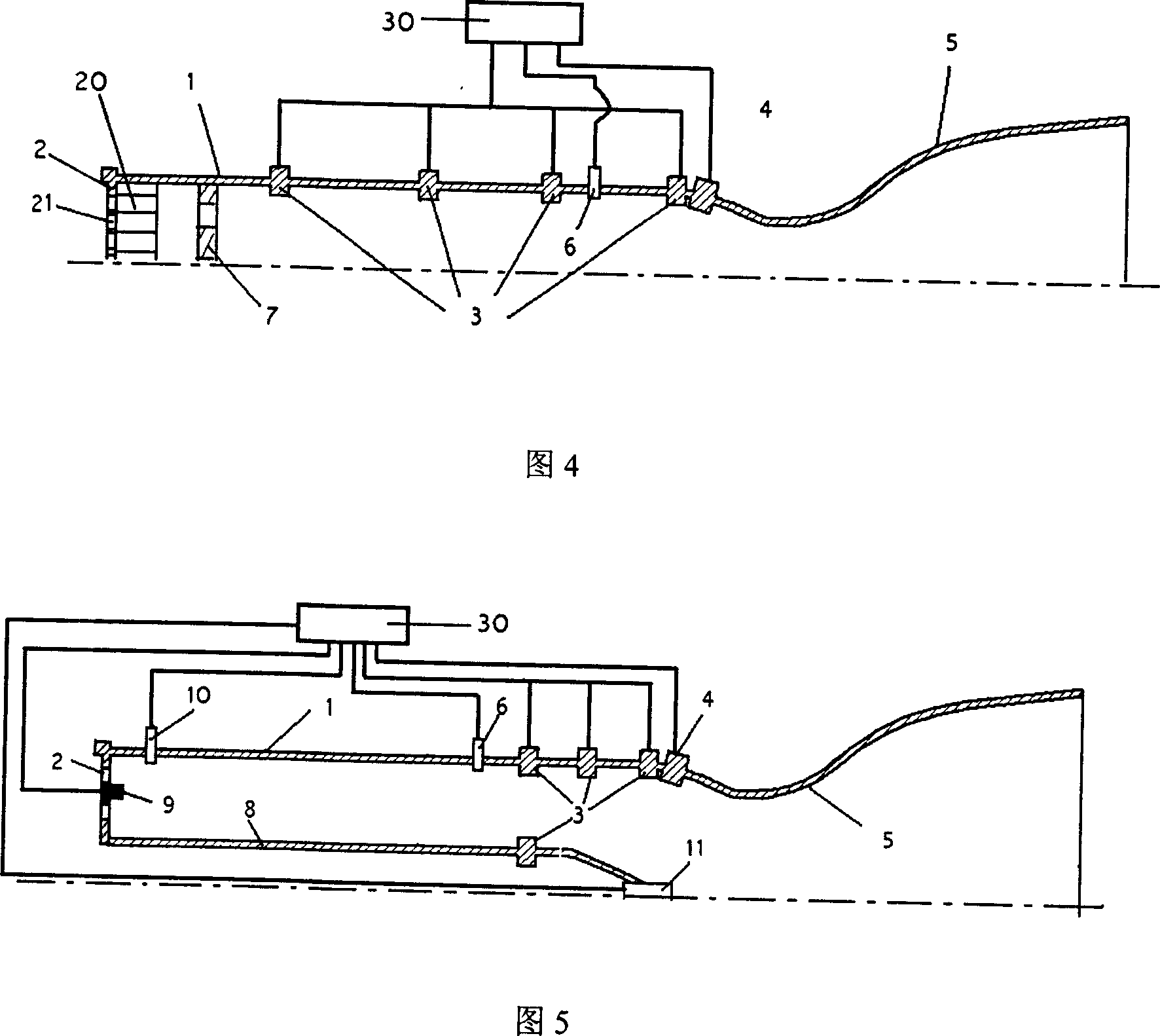

[0035] Embodiment 1, as shown in FIG. 4 , includes a pulse detonation engine combustion chamber housing 1 with an inner diameter of 100 mm and a length of 500 mm. Main propellant injection panel 2, secondary propellant nozzle 3, detonation auxiliary nozzle 4, nozzle 5, perforated plate 7, rectifier 20, control unit 30 and rear sensor 6, one end of the combustion chamber shell 1 is connected to the main propellant Injection panel 2, the other end is connected with nozzle 5; a rectifier 20 is fixedly connected on the main propellant injection panel 2, each channel of the rectifier 20 corresponds to a main propellant injection on the main propellant injection panel 2 Hole 21, the length of the rectification channel is 20mm. A perforated plate 7 is installed on the main propellant injection panel 2 and 100mm downstream. The clogging ratio of the perforated plate 7 is 0.4, and the Ф3 small holes are evenly distributed. 24 secondary propellant nozzles 3 are evenly distributed in si...

Embodiment 2

[0037] Embodiment 2, as shown in Figure 5, includes a pulse detonation engine combustion chamber housing 1, a main propellant injection panel 2, a secondary propellant nozzle 3, an auxiliary detonation nozzle 4, a nozzle 5, a rear sensor 6, a head Secondary propellant nozzle 9 , igniter 11 , control unit 30 and combustion chamber casing 8 . Combustion chamber shell 1 internal diameter 150mm, long 500mm, and combustion chamber shell external diameter 75mm, long 500mm. One end of the combustion chamber housing 1 is connected to the main propellant injection panel 2, and the other end is connected to the nozzle 5; the secondary propellant nozzles 3 are evenly distributed on the rear section of the combustion chamber housing 1 and the combustion chamber housing 8, and the detonation assists The nozzle 4 is located downstream of all secondary propellant nozzles 3 and before the nozzle throat; there is also a rear sensor 6 on the combustion chamber casing 1, which is located 100mm u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com