Single-tube rotary valve type double-bypass pulse detonation engine

A technology of pulse detonation and rotary valve, which is applied in the direction of machines/engines, mechanical equipment, jet propulsion devices, etc. It can solve the problems of high valve driving power, large volume and weight, and complex structure, and achieve light weight, small volume, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

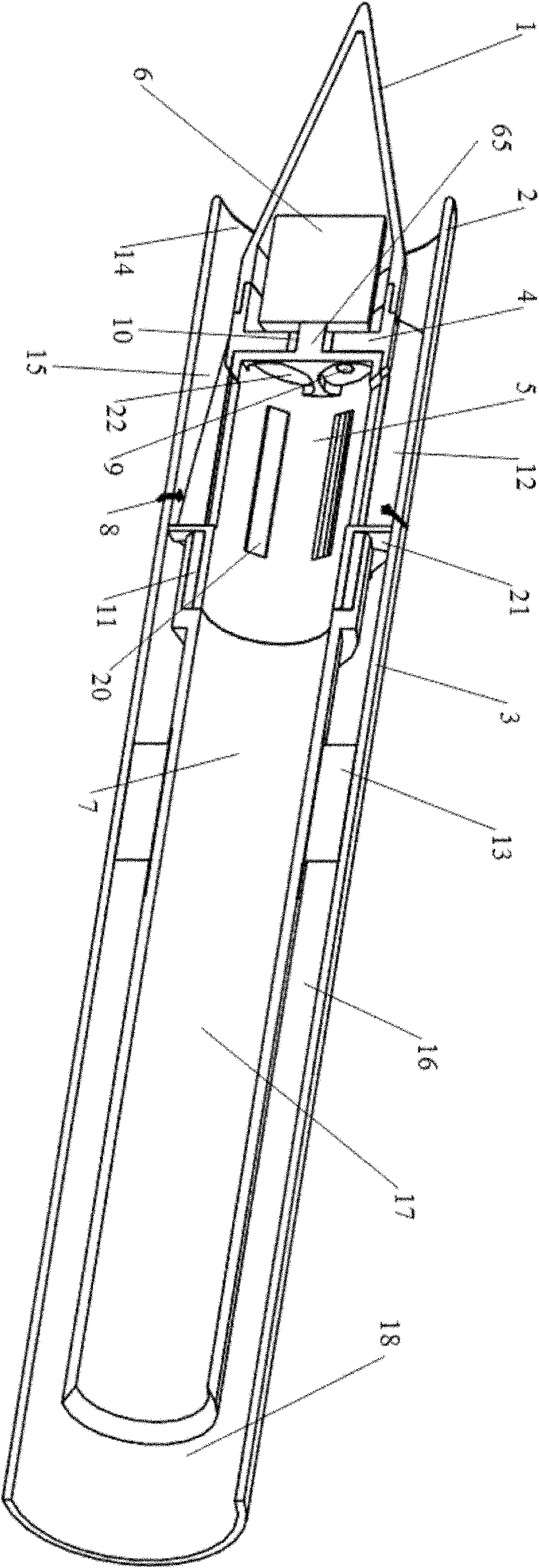

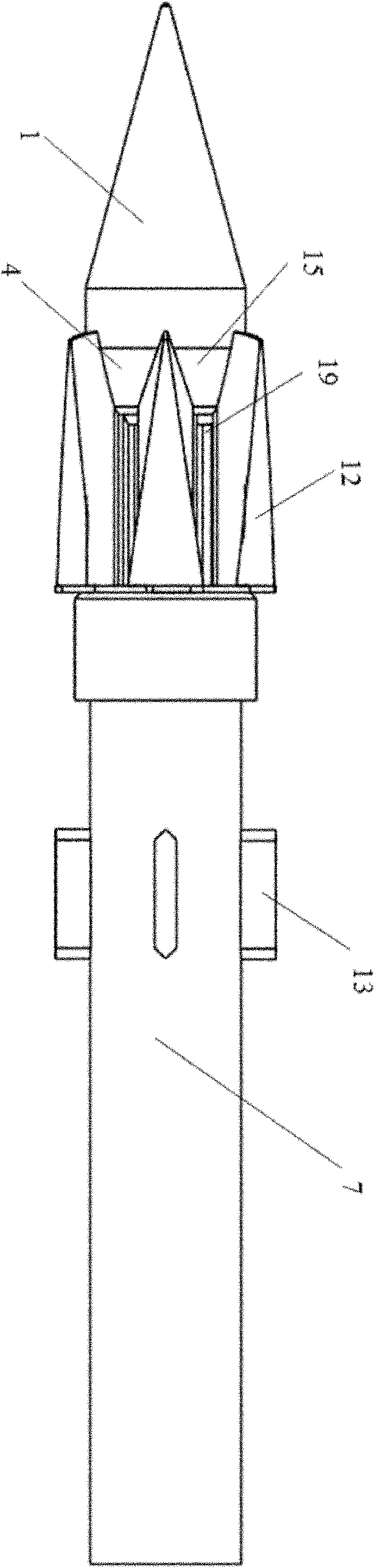

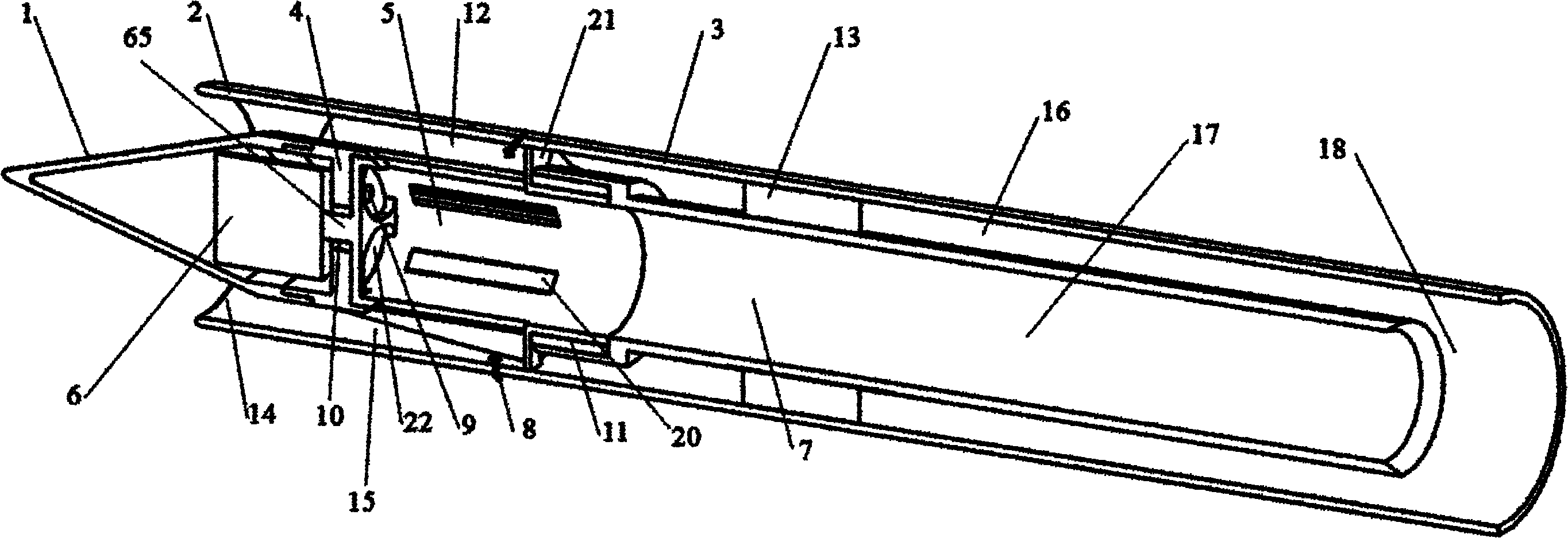

[0011] see figure 1 and figure 2 As shown, the present invention discloses a single-pipe rotary valve type double-duct pulse detonation engine, a central cone 1, a lip cover 2 surrounding the central cone 1, and an outer shell 3 extending from the lip cover 2 along the longitudinal direction , the thrust wall barrel 4 extending from the central cone 1, the barrel valve 5, the drive motor 6 connected to the barrel valve 5 and used to drive the barrel valve 5 to rotate, and the barrel valve 5 to penetrate and be located in the outer shell 3 Detonation tube 7, igniter 8, fuel nozzle 9, front bearing 10, rear bearing 11, front support 12 and rear support 13. The cylindrical valve 5 and the driving motor 6 are located inside the thrust wall cylinder 4; the cylindrical valve 5 is provided with a plurality of inner air intake holes 20 and an auxiliary air intake baffle 21 located at the rear end of the inner air intake holes 20, so that The thrust wall cylinder 4 is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com