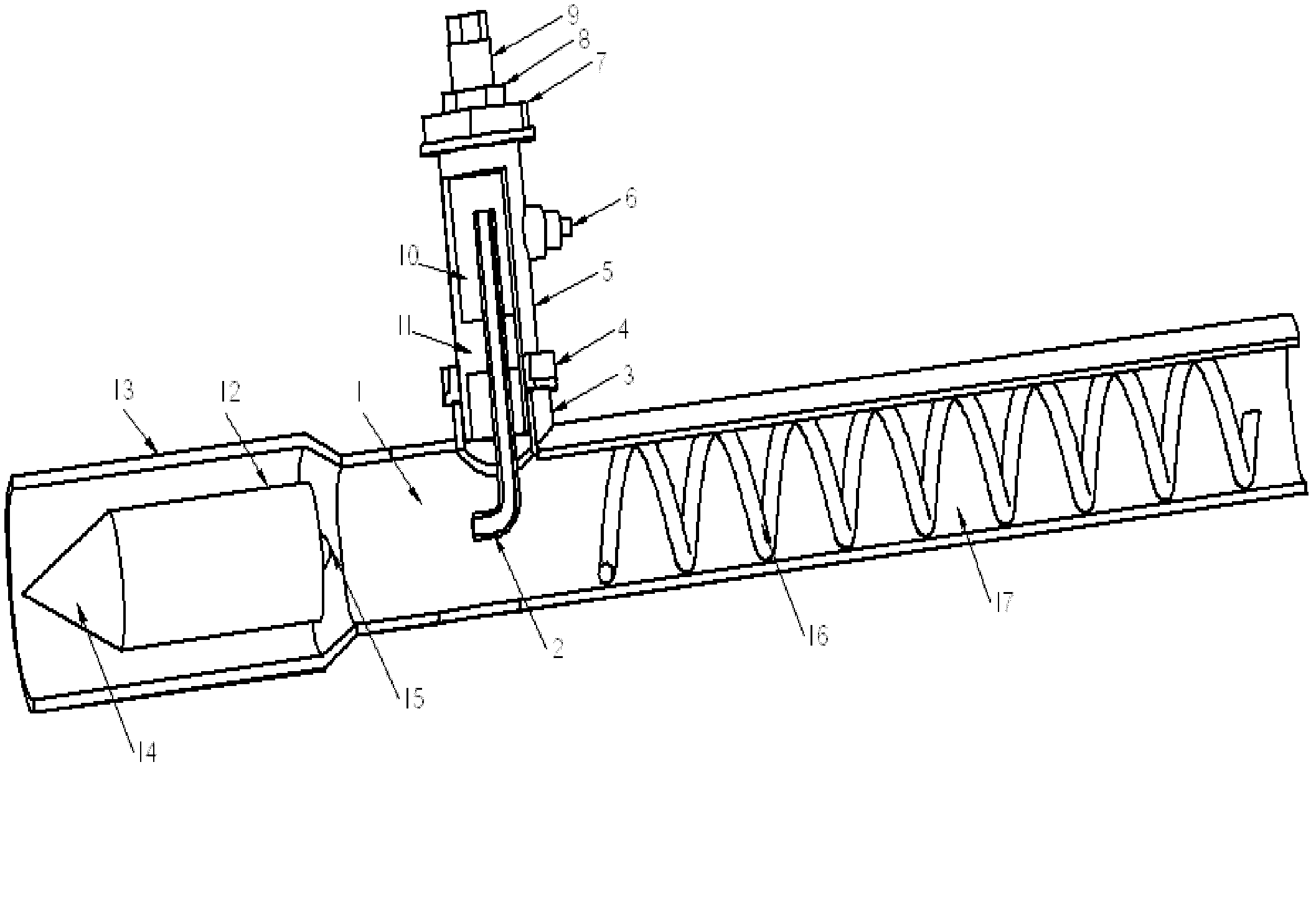

Jet ignition device of pulse detonation engine

A pulse detonation and ignition device technology, which is applied in rocket engine devices, machines/engines, intermittent injection devices, etc., can solve the problems of low ignition energy, long DDT distance, and increased system complexity, so as to improve operating frequency, The effect of shortening length, shortening time and distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

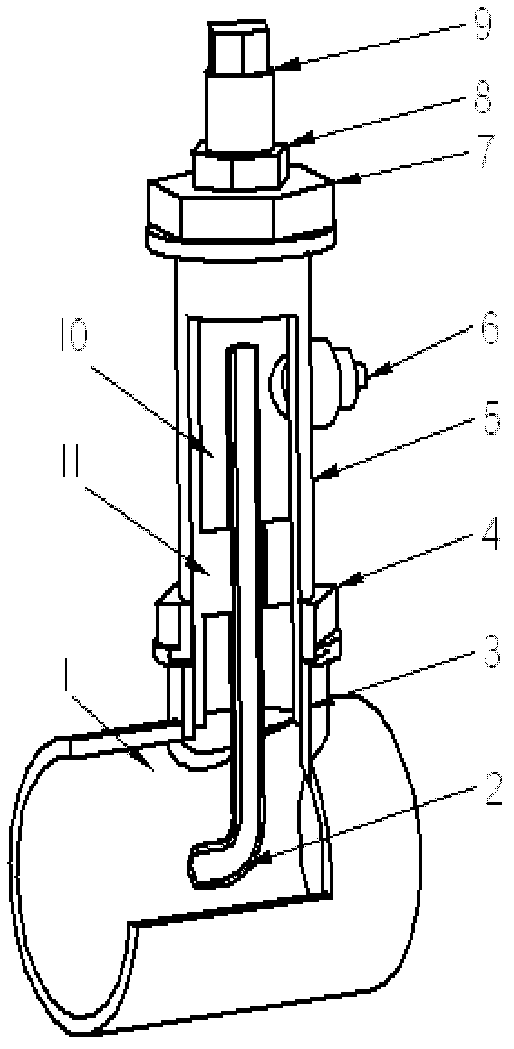

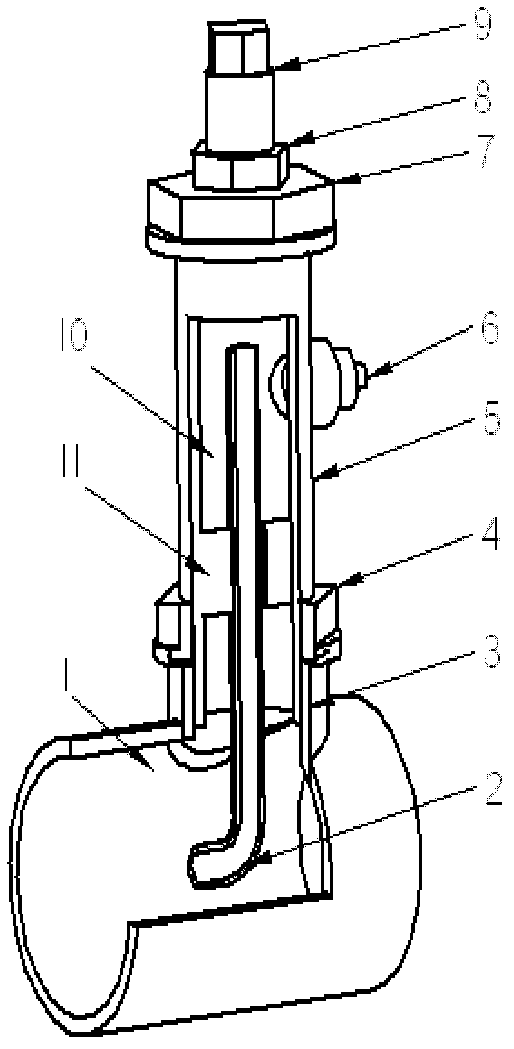

[0016] This embodiment includes mixing chamber 1, drainage tube 2, ignition seat 3, jet tube 5, igniter 6 and adjustment plug 9; jet tube 5 is fixedly connected with mixing chamber 1 through sealing fastening nut 4, jet tube 5 is connected with mixing The installation angle of the chamber 1 is 90°; the adjusting plug 9 is installed on the top of the jet tube 5 through the sealing nut 7 and the fastening nut 8; The tube is connected, and the lower end extends into the mixing chamber 1, the ratio of the inner diameter of the drainage tube to the inner diameter of the jet tube is 0.3; the ignition seat 3 is placed on one side of the jet tube 5, and is located at the outlet end of the drainage tube 2; Part of the combustible gas mixture flows into the jet cavity 10 through the drainage tube 2, and the other part directly enters the jet cavity 10. After the two parts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com