supersonic rotary engine

A rotary engine, supersonic technology, applied in the field of thermal energy and power, can solve the problems of waste and low efficiency of power system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

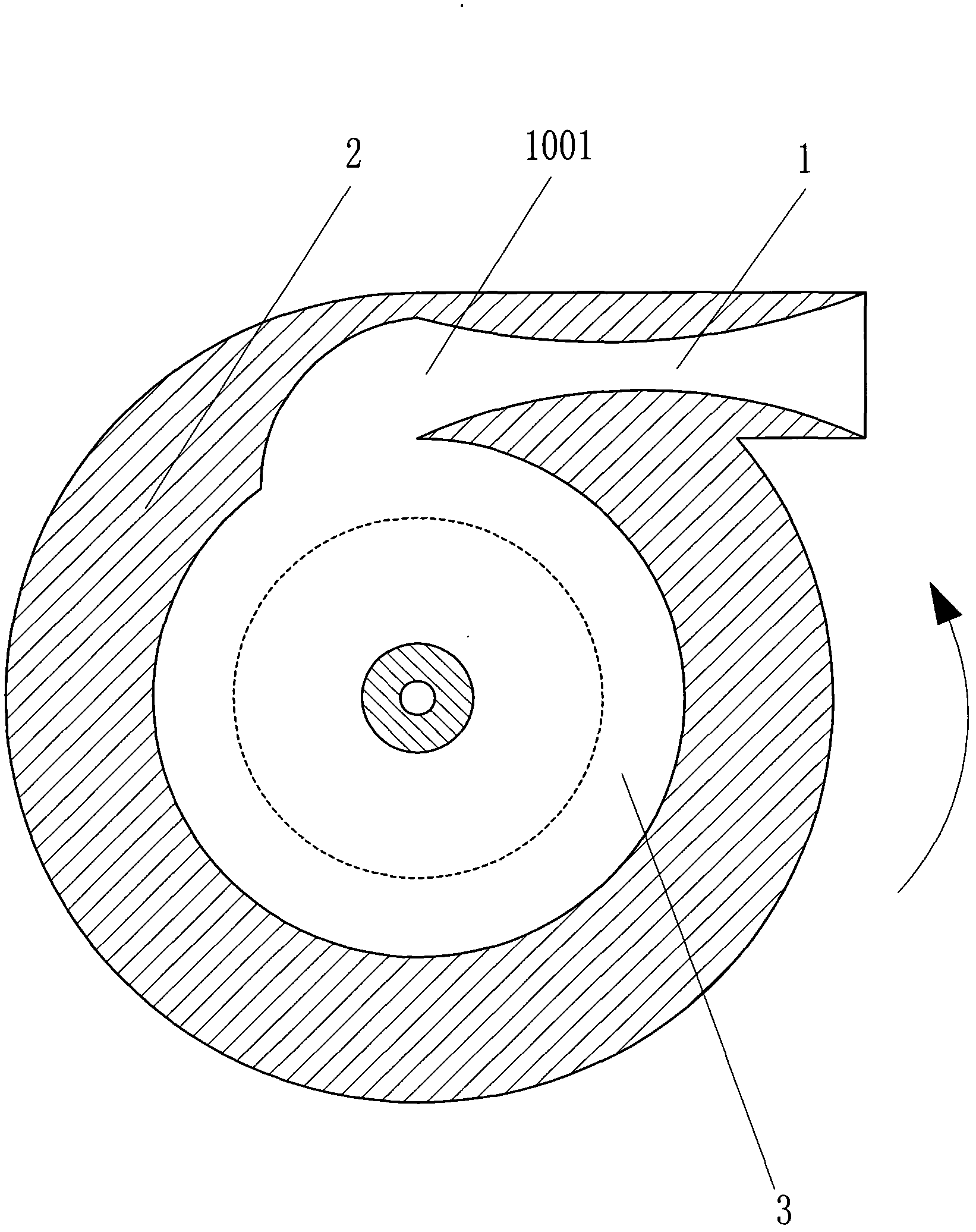

[0092] Such as figure 1The supersonic rotary engine shown includes a supersonic injection channel 1, a rotating structure 2 and a high-pressure working medium source 3. The supersonic injection channel 1 is arranged on the rotating structure 2, and the working medium inlet 1001 of the supersonic injection channel 1 is connected to the The high-pressure working medium source 3 is connected, and the pressure bearing capacity of the high-pressure working medium source 3 is greater than 2MPa. The injection direction of the supersonic jet channel 1 is generally directed at the tangent of the rotation circle of the rotating structure 2, and the rotating structure 2 outputs power to the outside. . When the supersonic rotary engine is working normally, the velocity of the airflow ejected from the supersonic injection channel is greater than Mach 2, and the static pressure of the airflow ejected from the supersonic injection channel is equal to the ambient pressure at the exit of the s...

Embodiment 2

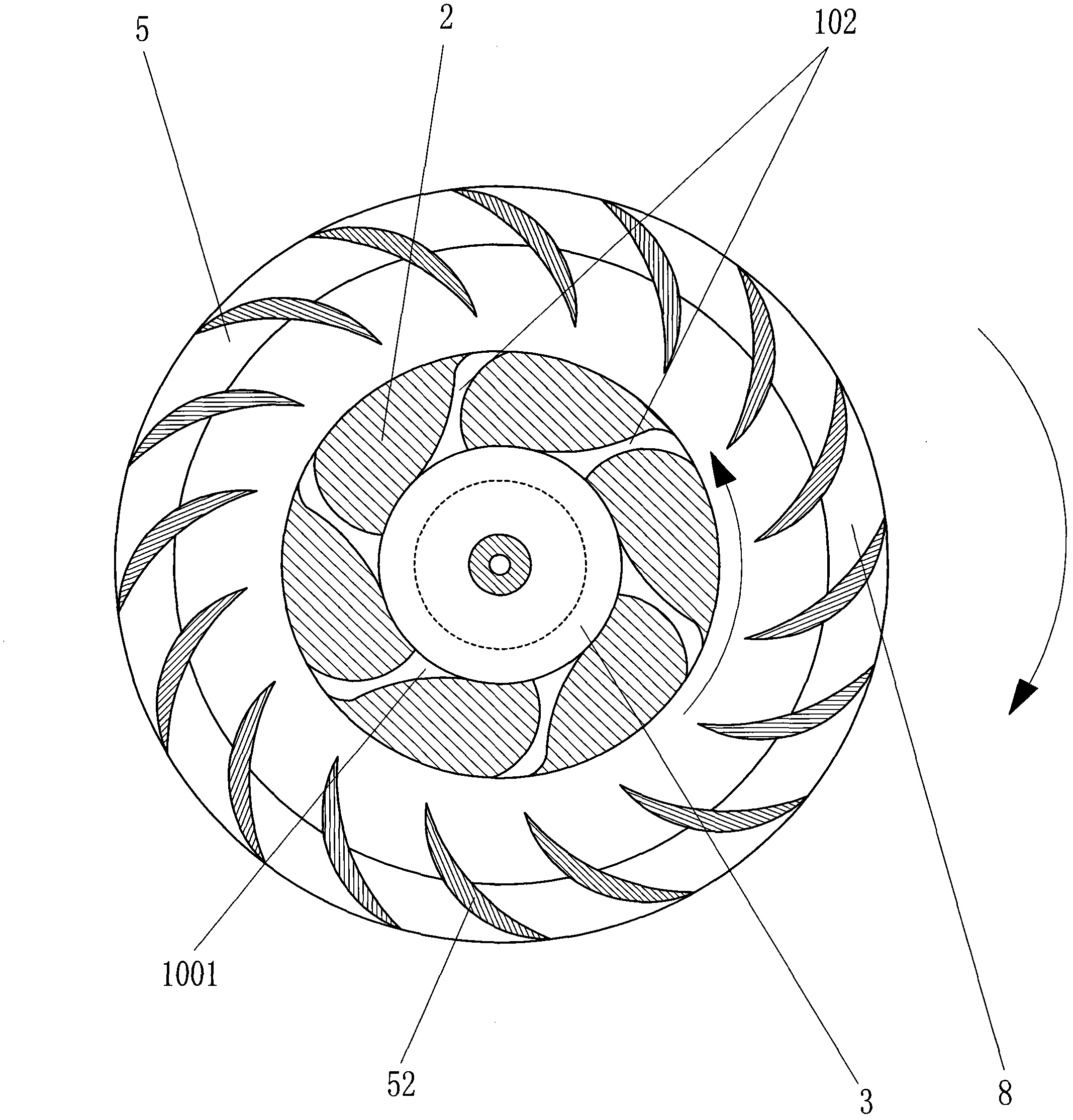

[0095] Such as figure 2 The difference between the shown supersonic rotary engine and Embodiment 1 is that the supersonic injection channel is set as the Laval nozzle 102, and the supersonic rotary engine also includes a passive rotating structure 5, and an impact is set on the passive rotating structure 5. The transmission structure 52, the jet air flow of the supersonic jet channel 1 impacts the passive rotating structure 5 on the impact transmission structure 52 to drive the passive rotating structure 5 to rotate, and the passive rotating structure 5 also outputs power to the outside. The passive rotating structure 5 is arranged on the periphery of the rotating structure 2 , and the working medium inlets 1001 of two or more Laval nozzles 102 communicate with a high-pressure working medium source 3 . The passive rotating structure 5 is provided with a diversion channel 8, and the jet flow of the supersonic jet channel 1 impacts and drives the passive rotating structure 5 an...

Embodiment 3

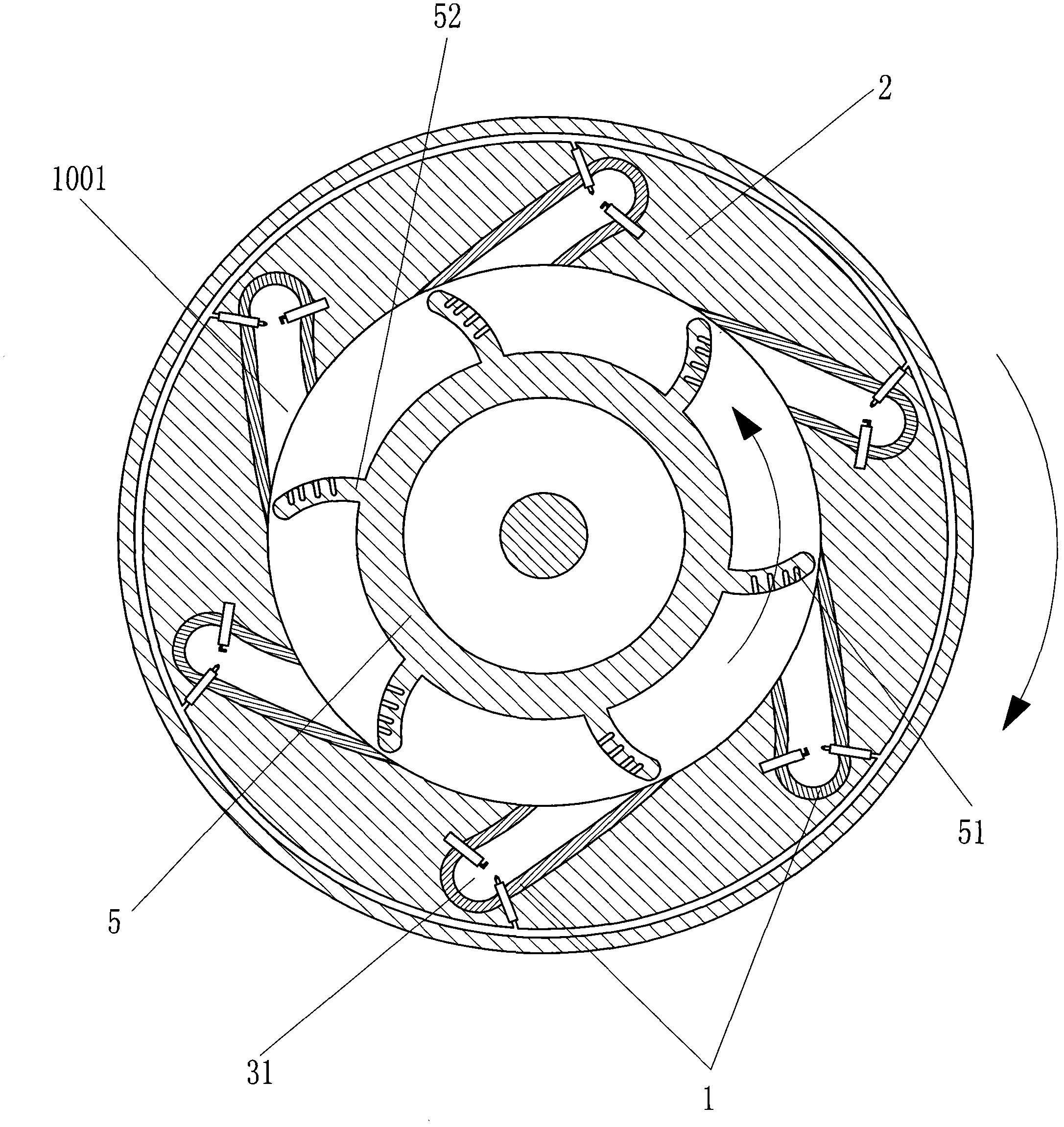

[0097] Such as image 3 The difference between the shown supersonic rotary engine and Embodiment 2 is that the high-pressure working medium source is set as a rocket combustion chamber 31, and the rotating structure 2 is arranged on the periphery of the passive rotating structure 5, and the passive rotating structure 5 is supersonic. An air-cushion buffer structure 51 is provided on the part where the high-speed jet stream impacts the sonic jet channel 1, and the air-cushion buffer structure 51 reduces the reflection of the high-speed jet stream. When the supersonic rotary engine is working normally, the velocity of the airflow ejected from the supersonic injection channel is greater than Mach 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com