Discharge lamp, in particular low pressure discharge lamp

A technology for low-pressure discharge lamps and discharge lamps, applied to low-pressure discharge lamps, discharge lamps, gas discharge lamps, etc., which can solve the problems of degraded photoelectric value, high working amalgam temperature, and high cost, and achieve the effect of improving regulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In the figures, identical or functionally identical elements are provided with the same reference symbols.

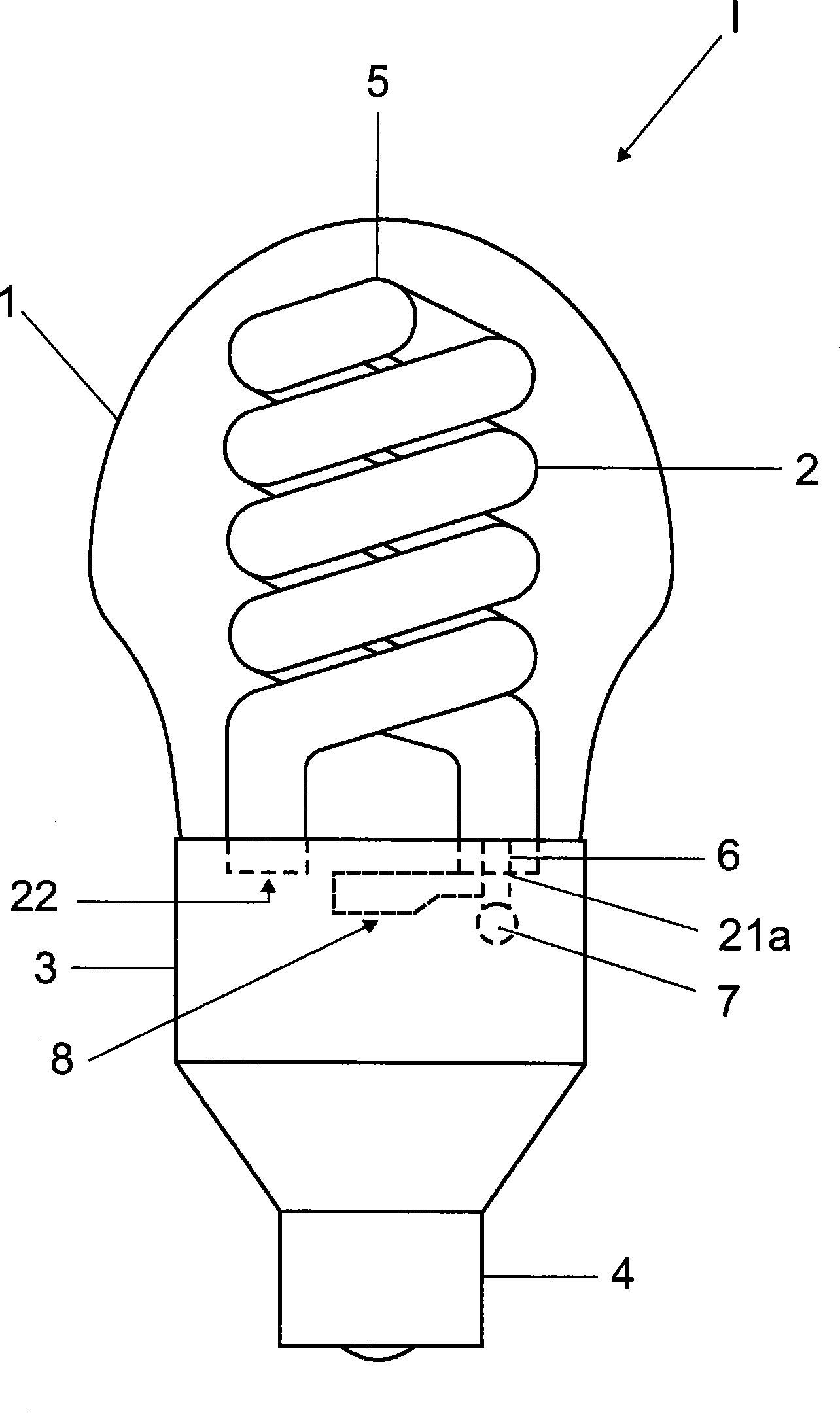

[0028] exist figure 1 shows a discharge lamp 1 constructed as a compact fluorescent lamp with an outer bulb 1 . The envelope bulb 1 surrounds a helically wound discharge vessel 2 . The tubular and helically wound discharge vessel 2 is connected to an electronic ballast, shown only by its housing 3 . The housing bulb 1 is also fastened to the housing 3 via locking elements.

[0029] On the side facing away from the enveloped bulb 1 , the housing 3 of the ballast is terminated by a standardized base 4 . In this embodiment, the discharge vessel 2 consists of two coiled discharge tubes which meet each other in a region 5 .

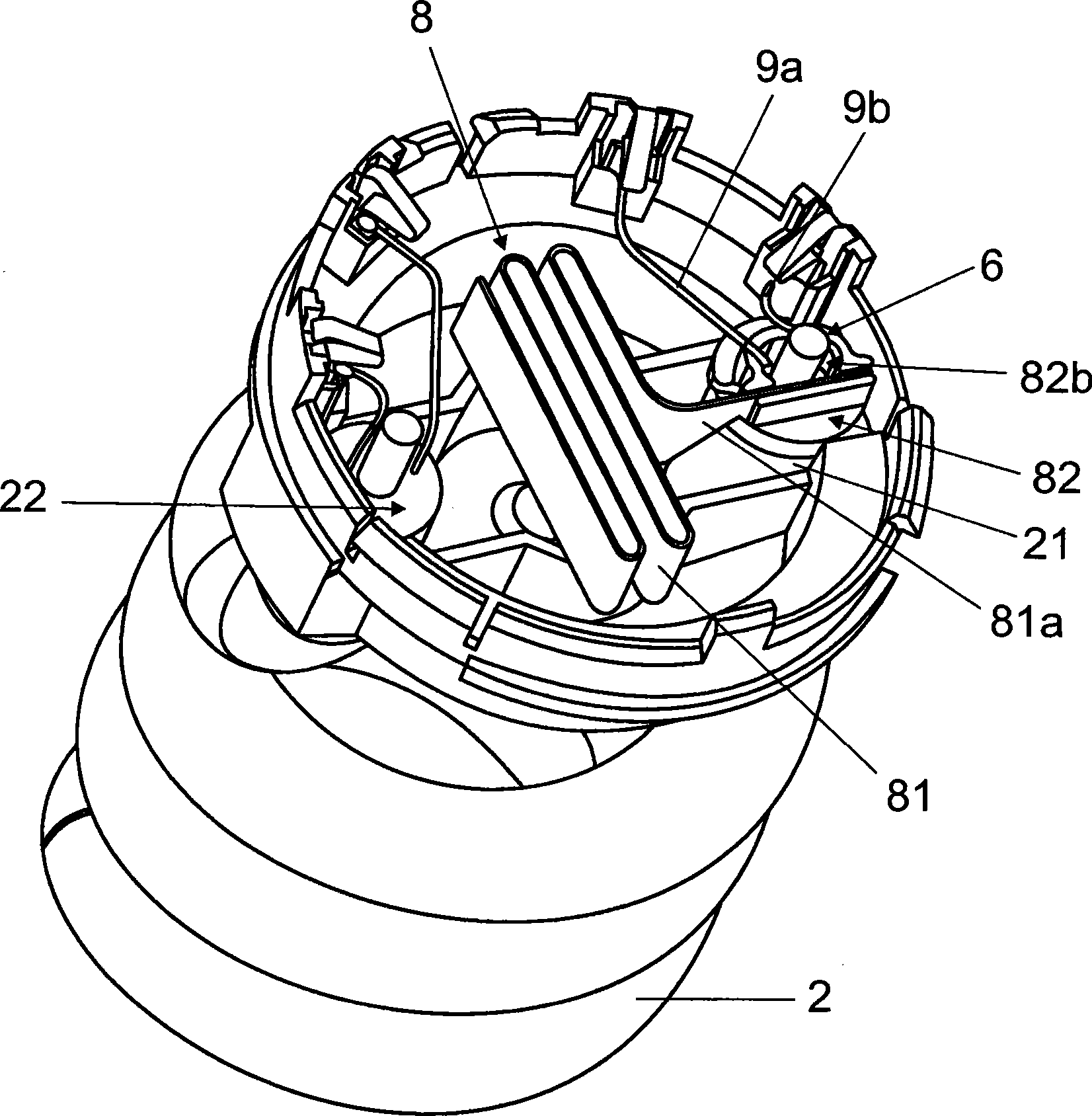

[0030] The two ends 21 and 22 of the discharge vessel 2 are arranged substantially opposite each other and with the same orientation in the direction of the housing 3 . as from figure 1 As can be seen in the view of , these ends 21 and 22 e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com