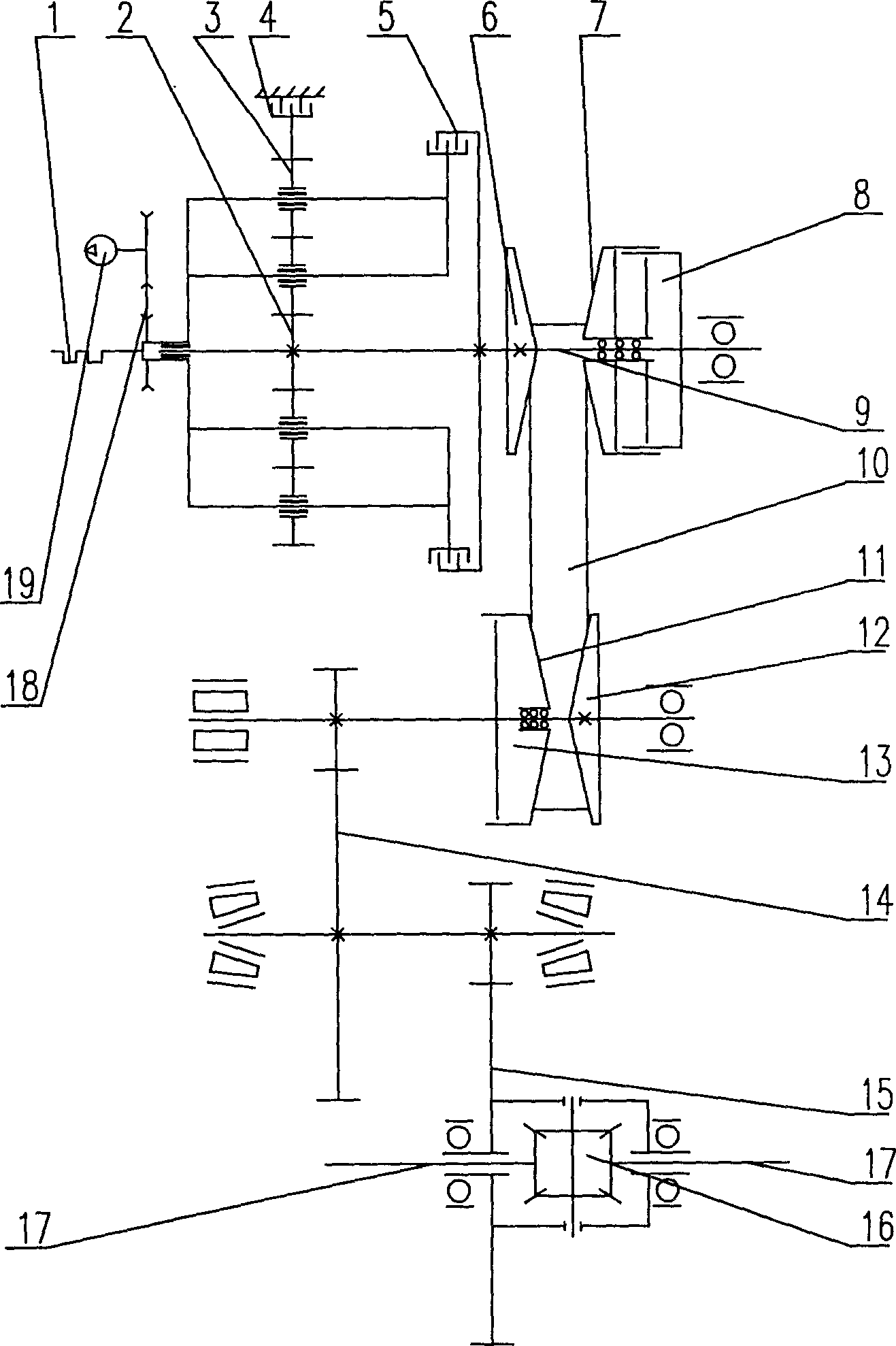

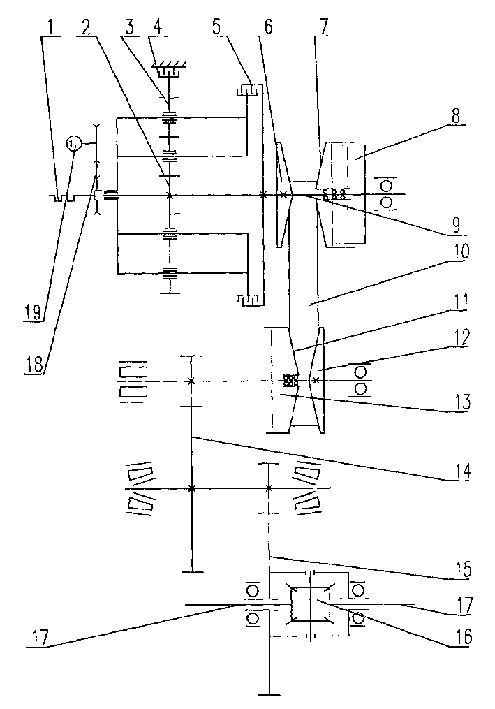

Stepless speed change gearing device

A transmission device and continuously variable speed technology, which is applied in the transmission field, can solve the problems such as difficult layout of the axial size, achieve the effect of reducing the axial size, meeting the design requirements, and improving the starting characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The embodiment given in conjunction with the accompanying drawings further illustrates that the engine output shaft 1 is linked with the forward gear clutch frame provided in the transmission book, and the power is transmitted to the oil pump 19 through the sprocket drive pair 18, and the forward gear clutch hub is connected with the gearbox main shaft 9, The active cone wheel linkage, the active cone wheel includes a fixed cone 6 and a moving cone 7 oppositely arranged, the fixed cone 6 is located on one side of the forward gear clutch 5, and the outside of the moving cone 7 of the driving wheel is provided with a pressure cylinder 8, and the same The driven cone wheel also includes a fixed cone 12, a moving cone 11 and a pressure cylinder 13 which are arranged oppositely. The axial distance between the two conical discs of the disc wheel makes the metal conveyor belt assembly 10 move radially, thereby changing the transmission radius of the driving and driven conical d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com