Start control device of internal combustion engine

A technology for starting control device and internal combustion engine, which is applied in engine control, fuel injection control, internal combustion piston engine, etc., can solve the problems of unreliable, unreliable, and heavy load of engine starting characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

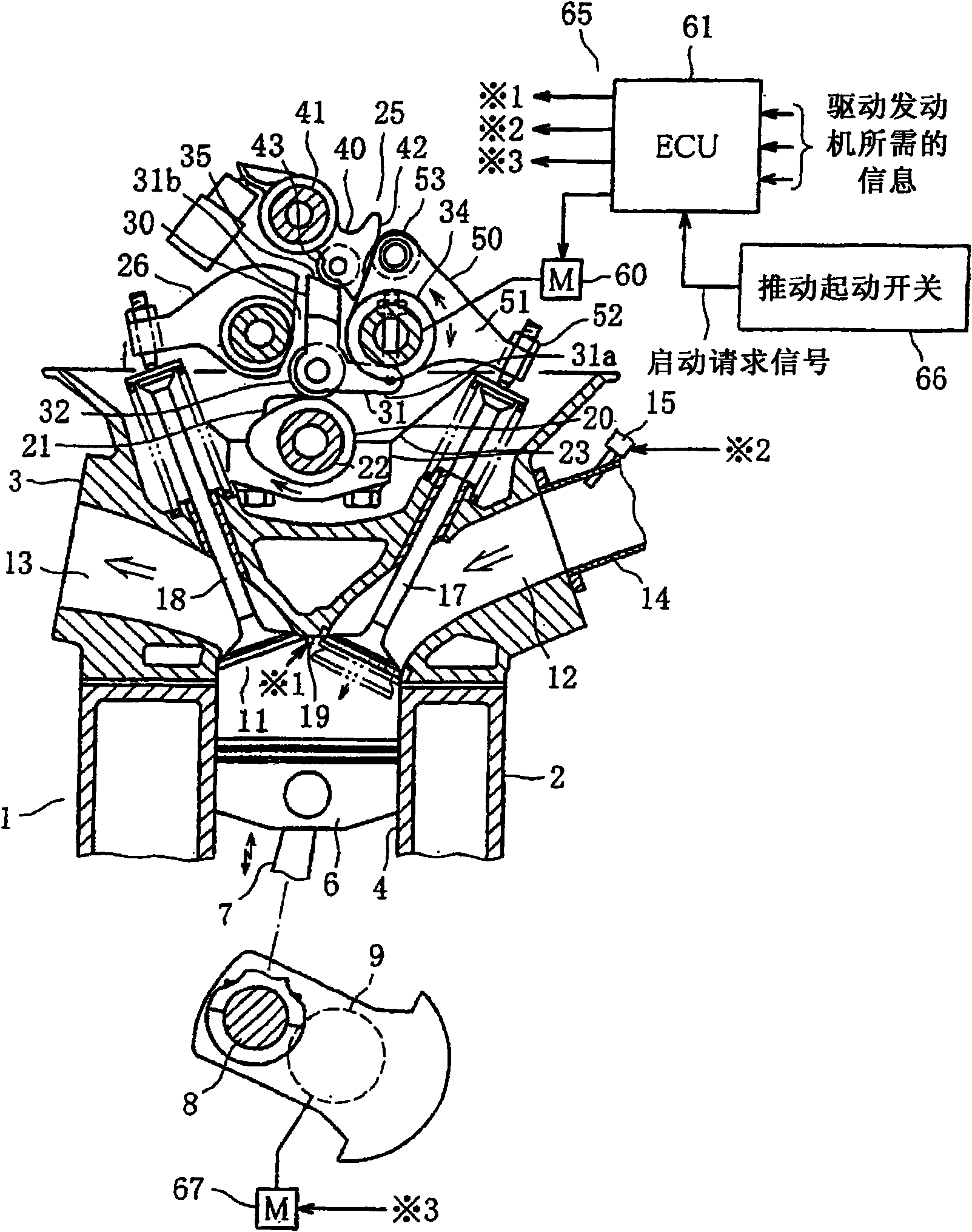

[0038] In the following, based on Figure 1 to Figure 4 The invention will be described with reference to a first embodiment shown.

[0039] figure 1 Schematically shows part of an internal combustion engine, such as a reciprocating SOHC engine 1 that can use alcohol blended fuel (mixed fuel), and the control system of the same engine 1 .

[0040] First, describe Engine 1, in figure 1 In , reference numeral 2 denotes a cylinder block, and reference numeral 3 denotes a cylinder head mounted on an upper portion of the cylinder block 2 . In these cylinder blocks 1, cylinders 4 (only partly shown) are formed. Inside the cylinder 4, a piston 4 is mounted for reciprocating motion. The piston 6 is connected to a crankshaft 9 provided on the lower part of the cylinder block 2 via a connecting rod 7 and a crankpin 8 .

[0041] In the lower surface of the cylinder head 2, a combustion chamber 11 is formed. On both sides of the combustion chamber 11, an intake port 12 and an exhaus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com