Equal-proportional four-stage hydraulic-mechanical compound stepless transmission

A technology of hydraulic machinery and stepless transmission, applied in the field of vehicle transmission, can solve the problems of unfavorable transmission system power density and reliability improvement, large volume and weight, complicated control of the starting clutch, etc., and achieves good starting characteristics, high transmission efficiency, compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

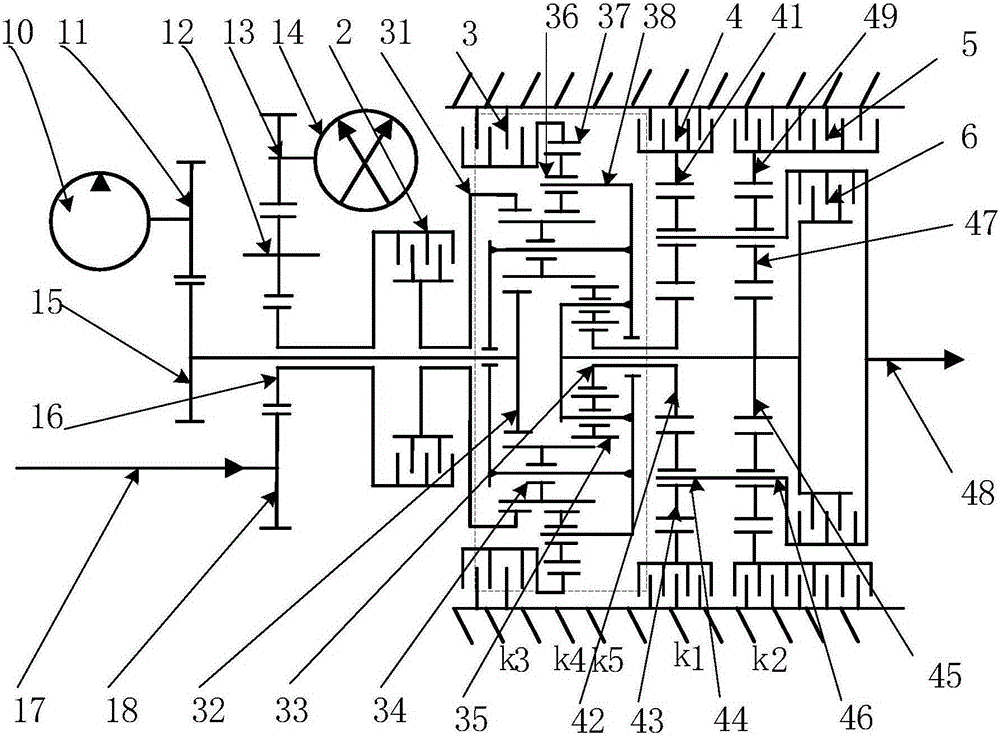

[0017] See attached figure 1 , one An equal-ratio four-stage hydraulic-mechanical compound stepless transmission device, composed of planetary row k3, planetary row k4, planetary row k5 and the ring gear 37 of the hydraulic section planetary row to form a positive and negative confluence planetary mechanism, and planetary row k1, planetary row 3-speed transmission mechanism composed of row k2 planetary row;

[0018] Engine input shaft 17 is connected to input gear 18; gear B16 meshes with input gear 18 on the one hand, and meshes with transition gear 12 on the other hand; transition gear 12 meshes with hydraulic pump gear 13, and hydraulic pump gear 13 is connected with hydraulic pump 14; Clutch C0 is connected with gear B16 and the ring gear 31 of the positive and negative confluence planetary mechanism; the hydraulic motor 10 is connected with the hydraulic motor gear 11, and the hydraulic motor gear 11 meshes with the gear A15, and the gear A15 is connected with the large...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com