Three-section-type electromechanical composite stepless transmission device for wheel-type load-carrying vehicle

An electromechanical composite, stepless transmission technology, applied in the direction of gear transmission, transmission, mechanical equipment, etc., can solve the problem that the transmission ratio adjustment range is difficult to meet the load-bearing vehicle, etc., and achieve good starting performance, improve power density, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

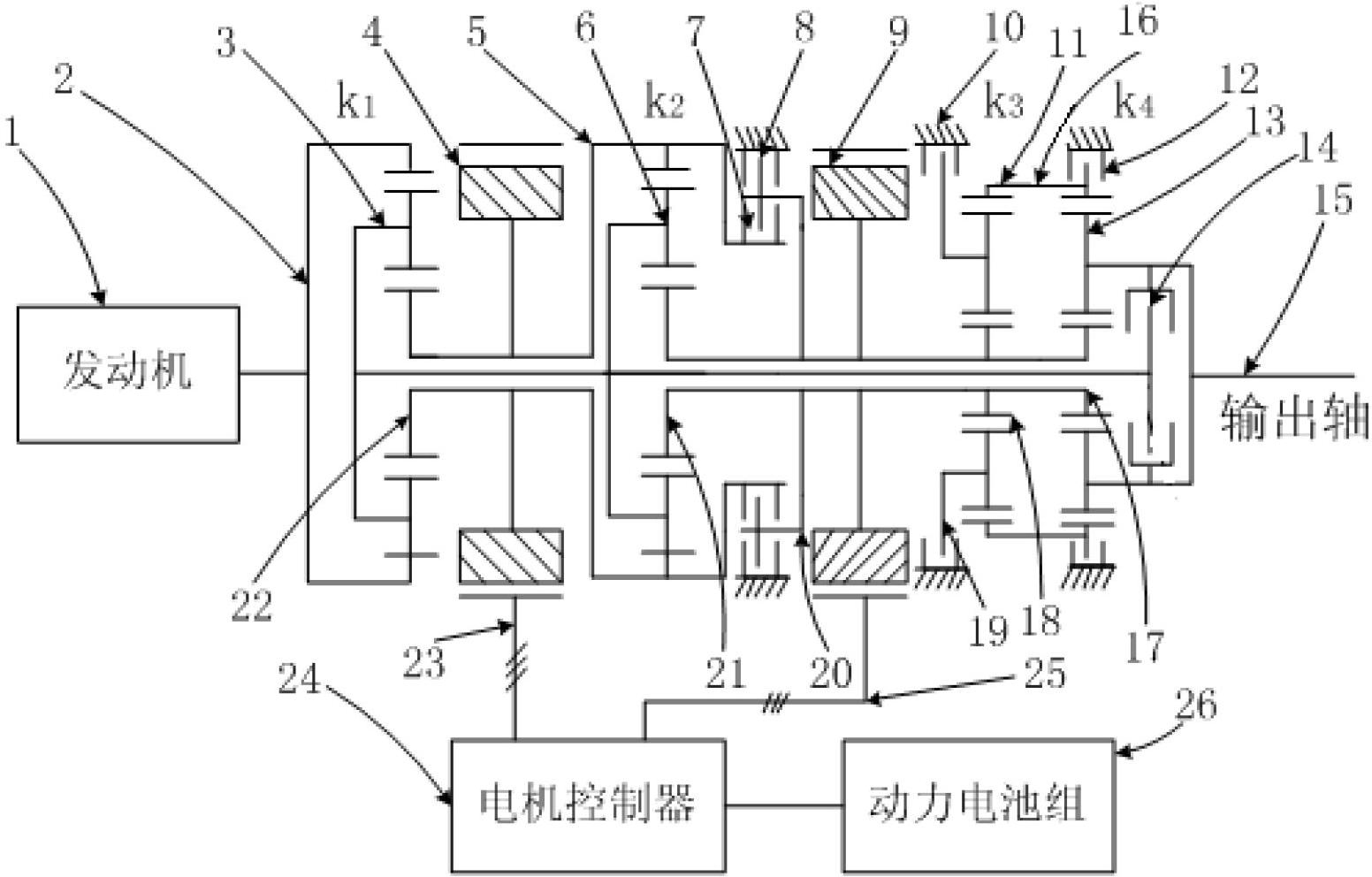

[0026] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings and examples. The following examples are only used to illustrate the technical solutions of the present invention more clearly, but not to limit the protection scope of the present invention.

[0027] Such as figure 1 As shown, the technical solution of the present invention is a three-stage electromechanical compound stepless transmission device for wheeled trucks, including engine 1, k1 planetary row, k2 planetary row, k3 planetary row, k4 planetary row, motor a4 , motor a cable 23, motor b9, motor b braking member 20, motor b cable 25, clutch a7, clutch b14, brake a8, brake b10, brake c12, capacity output shaft 15, motor controller 24 and power battery pack 26 ;

[0028] Among them, the k1 planetary row is composed of the k1 planetary row ring gear 2, the k1 planetary row sun gear 22 and the k1 planetary row carrier 3;

[0029] The k2 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com