Discharge lamp with an auxiliary ignition element

A technology for auxiliary components and discharge lamps, applied in discharge lamps, gas discharge lamps, high-pressure discharge lamps, etc., can solve problems such as safety risks and devitrification of discharge vessels, and achieve the effect of preventing electrolysis and improving starting characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Refer to the following The invention is explained in the context of high-pressure discharge lamps, which are used, for example, in microscopy or in plastics technology. However, the discharge lamp according to the invention is by no means limited to such a discharge lamp.

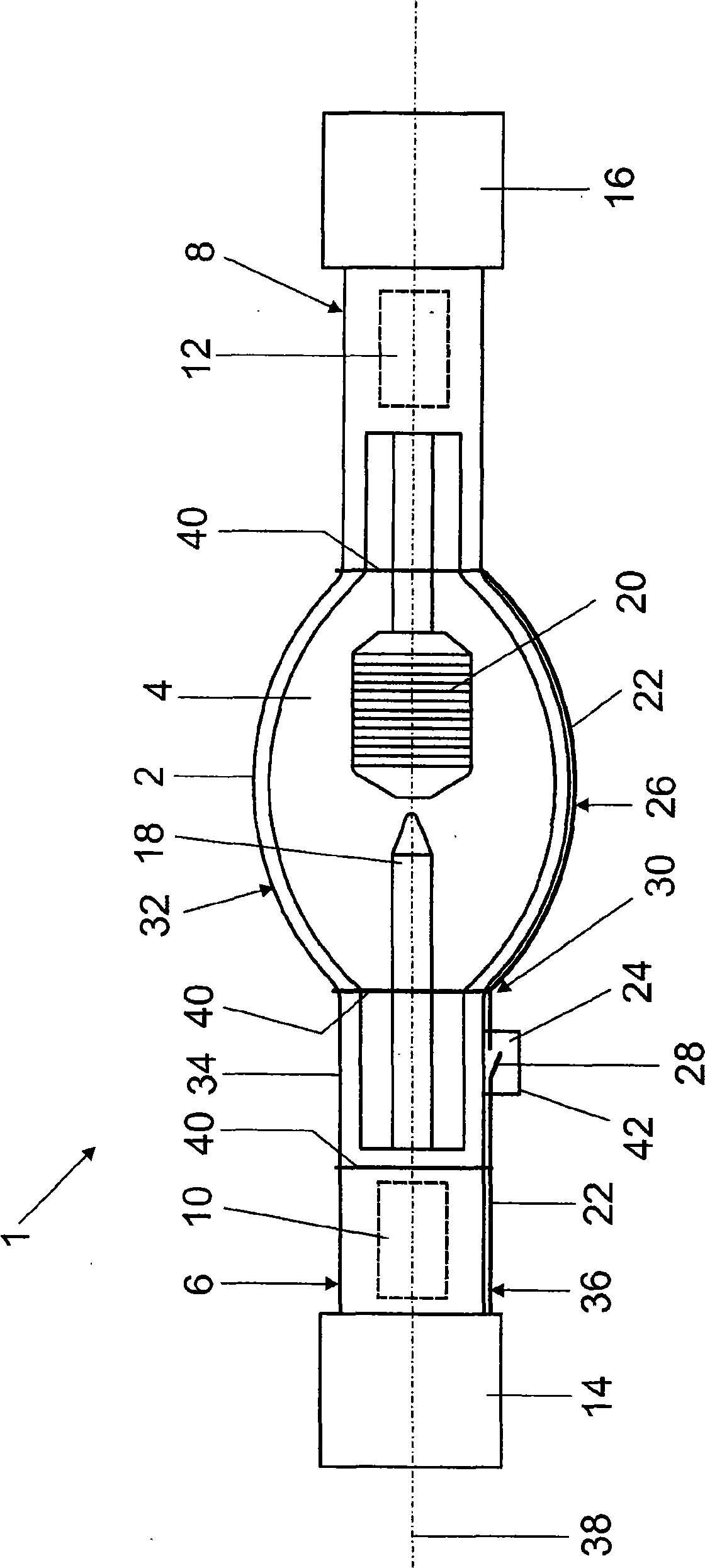

[0015] The only figure shows the use of short arc technology to form the lamp cap on both sides Schematic view of a high-pressure discharge lamp 1 . The discharge lamp has a discharge vessel 2 made of quartz glass with an inner space 4 and two diametrically opposed sealed base necks 6 , 8 each having a schematically indicated molybdenum film The not-shown power supply of the seals 10 , 12 is also provided with cap sockets 14 , 16 . Two diametrically opposed electrodes 18 , 20 protrude into interior space 4 , which electrodes are each connected to one of the power supply devices and between which a gas discharge is formed during lamp operation. For this purpose, an ionizable filling is contained...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com