Rotor of synchronous magneto resistance motor

A synchronous reluctance motor and rotor technology, applied in synchronous machines, synchronous motors for single-phase current, magnetic circuit rotating parts, etc., can solve problems such as affecting motor characteristics, reducing motor starting characteristics, etc., to improve starting characteristics. , the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

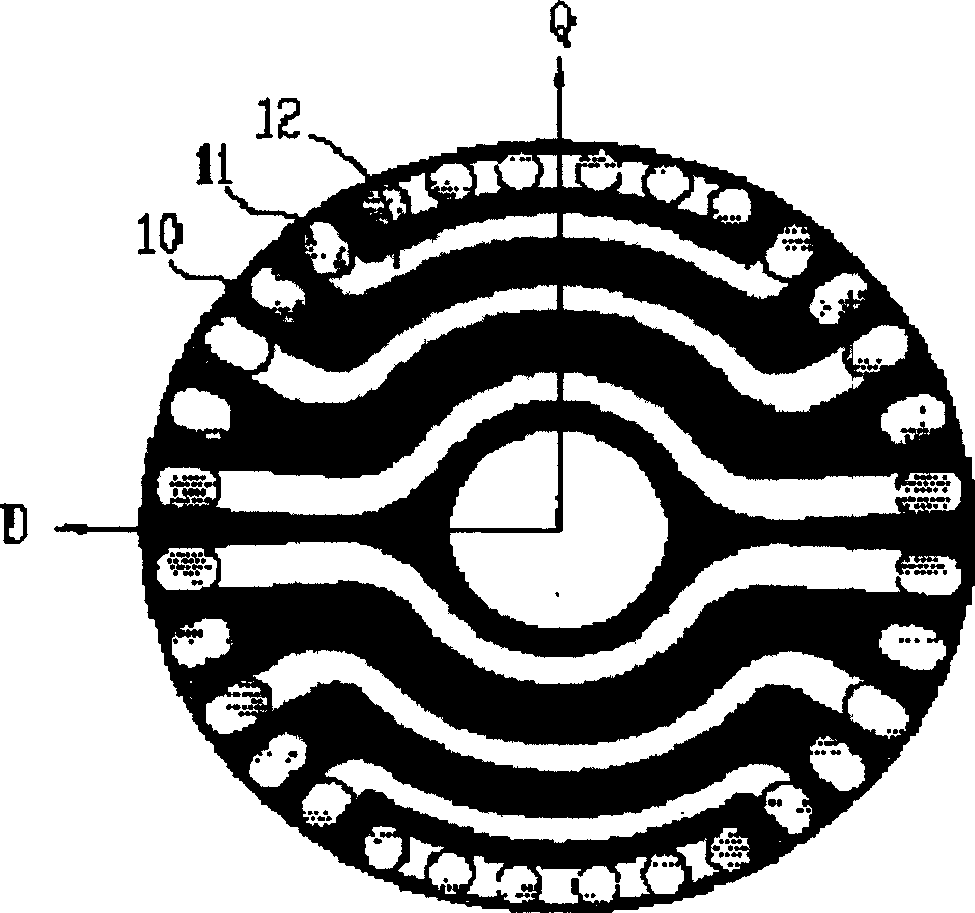

[0026] Figure 4 It is a plan view of the rotor structure of the synchronous reluctance motor of the present invention.

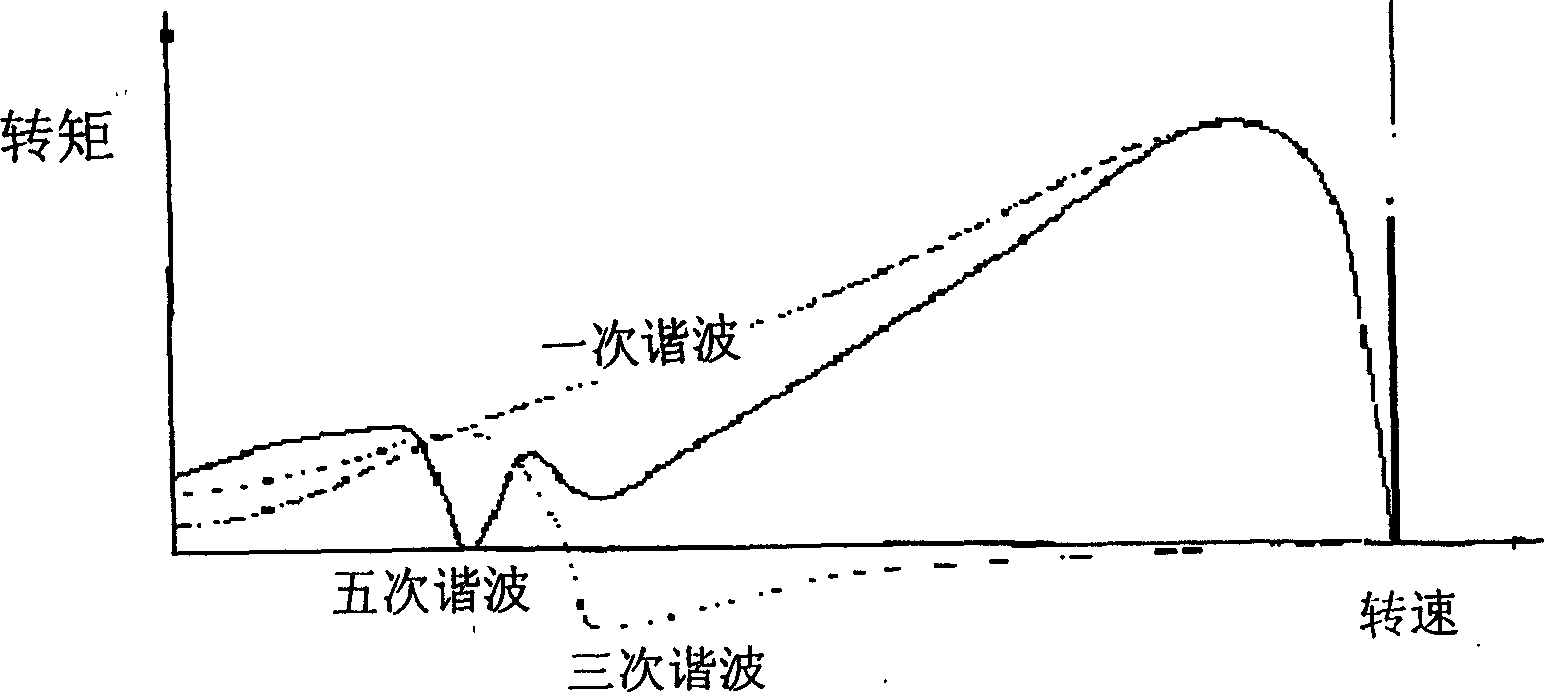

[0027] Figure 5 It is a comparison chart of the simulated experiment data of the starting effect of the existing common synchronous reluctance motor and the synchronous reluctance motor of the present invention after adding a load.

[0028] like Figure 4 As shown, the rotor of the synchronous reluctance motor of the present invention includes: an iron core 10, several conductor bars evenly embedded in the outer peripheral surface of the iron core 10 and several separators 12 inserted into the iron core 10; 12 around the rotor shaft and divided into two groups symmetrical to each other centered on the rotor shaft.

[0029] The conductor rods include: conductor rods 11 embedded in the outer peripheral surface of the iron ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com