Polymer electrolyte, polymer electrolyte membrane, membrane-electrode assembly, and solid polymer fuel cell

A polymer and electrolyte technology, applied in the direction of solid electrolyte fuel cells, fuel cells, fuel cell components, etc., can solve the problems of polymer electrolyte membrane, excellent durability and heat resistance, etc., and achieve excellent starting characteristics , excellent durability and heat resistance, the effect of excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0119] The present invention is further specifically described below by reference examples, examples and comparative examples, but the present invention is not limited thereto at all. As chemicals (compounds, etc.) used in Reference Examples, Examples, and Comparative Examples, those with the highest purity available were used, and those that were sufficiently degassed were used for solvents.

[0120] Confirmation of the structure of the products (intermediate compounds, final compounds) obtained in the Reference Examples, determination of the number average molecular weight of the polymers obtained in the Examples and Comparative Examples, and measurement of the polymer electrolytes or polymers obtained in the Examples and Comparative Examples were performed as follows The ion exchange capacity, membrane strength, ionic conductivity, linear expansion coefficient and methanol permeation rate of the electrolyte membrane and the dynamic mechanical test of the polymer electrolyte ...

reference example 1

[0144] Preparation of 1-(4-vinylphenyl)adamantane

[0145] 1-(4-Vinylphenyl)adamantane (20 g) was synthesized in the same manner as described in JP-A-2006-96988.

Embodiment 1

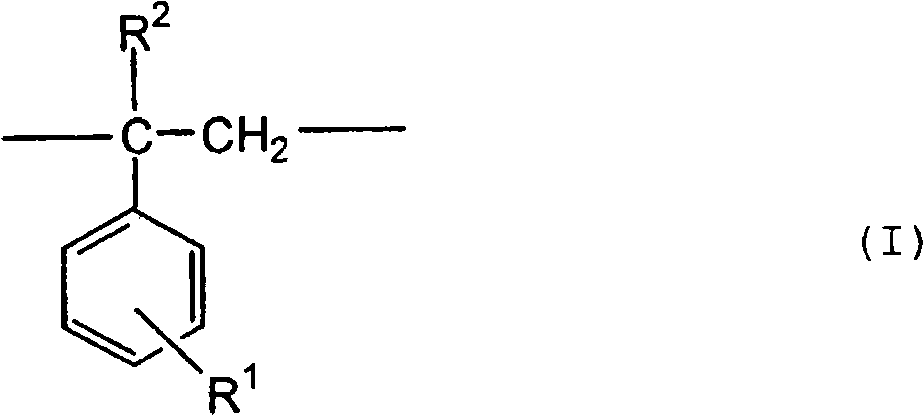

[0147] (a) comprising polystyrene (polymer block (A)), hydrogenated polyisoprene (polymer block (B)) and poly[1-(4-vinylphenyl)adamantane] (polymer Synthesis of block copolymers of object block (C))

[0148] After putting 526ml of dehydrated cyclohexane and 2.89ml of sec-butyllithium (1.3M cyclohexane solution) into a 1,400ml autoclave, add 1-(4-vinylphenyl)adamantane in cyclohexane solution (1 -(4-vinylphenyl) adamantane: 27g, cyclohexane: 200ml), 27.5ml styrene and 70.4ml isoprene, make them each carry out polymerization at 45 ℃, then add phenyl benzoate in 35.3 ml of a 3% by mass solution in cyclohexane to perform a coupling reaction, thereby synthesizing poly(1-(4-vinylphenyl)adamantane)-b-polystyrene-b-polyisoprene- b-polystyrene-b-poly(1-(4-vinylphenyl)adamantane) (hereinafter abbreviated as AdSSISAdS). The number average molecular weight (measured by GPC, converted to polystyrene) of the obtained AdSSISAdS was 136,400, which was obtained by 1 H-NMR measurement determ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com