Method for regulating the actual torque delivered by an electric machine in a motor vehicle to the nominal torque

A technology of rated torque and actual torque, applied in the direction of using engine-driven traction, motor vehicles, and the arrangement of multiple different prime movers of general power plants, which can solve the problem of expensive protection measures, high additional costs, and high integration costs. and other problems, to achieve the effects of improved starting characteristics, low consumption and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

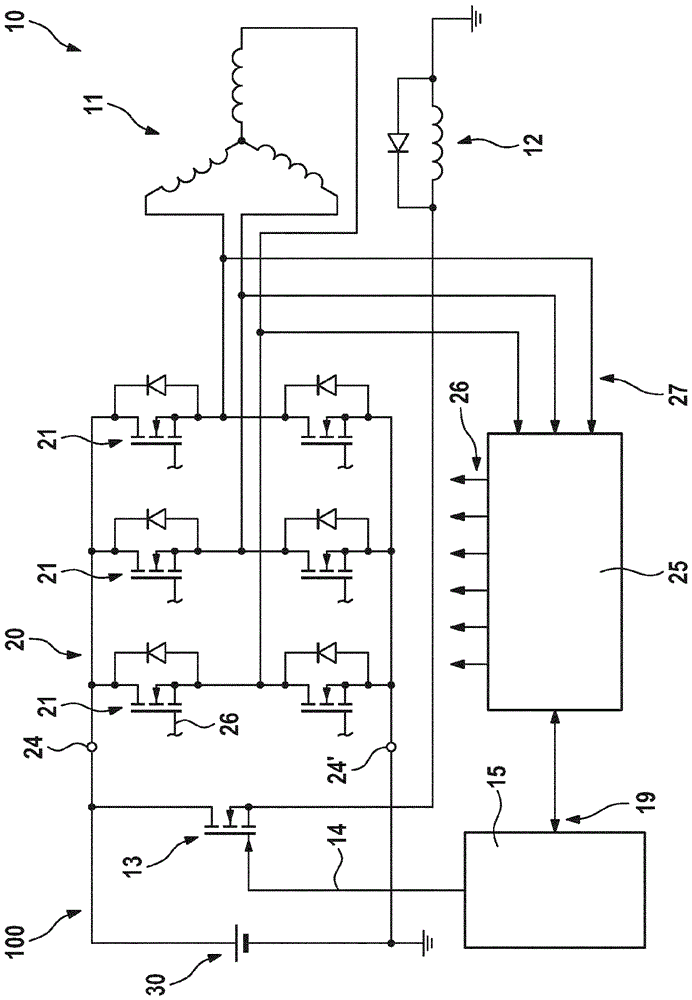

[0026] exist figure 1 An electric machine on which the invention may be based is shown in a wiring diagram in FIG. 2 and is generally designated 100 . The electric machine has a generator part 10 and a converter part 20 . The converter components are usually operated as a rectifier during generator operation of the machine and as an inverter during motor operation.

[0027] Generator part 10 is shown only schematically in the form of a star-connected stator winding 11 and an excitation winding or rotor winding 12 connected in parallel with diodes. The rotor winding is pulsed switched by a power switch 13 , which is connected to a connection 24 of the converter part 20 . The actuation of the power switch 13 is carried out according to the standard of a field regulator 15, wherein the power switch 13 is usually integrated in the application-specific integrated circuit (ASIC) of the field regulator like a diode connected in parallel with the rotor winding 12 ASIC).

[0028] A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com